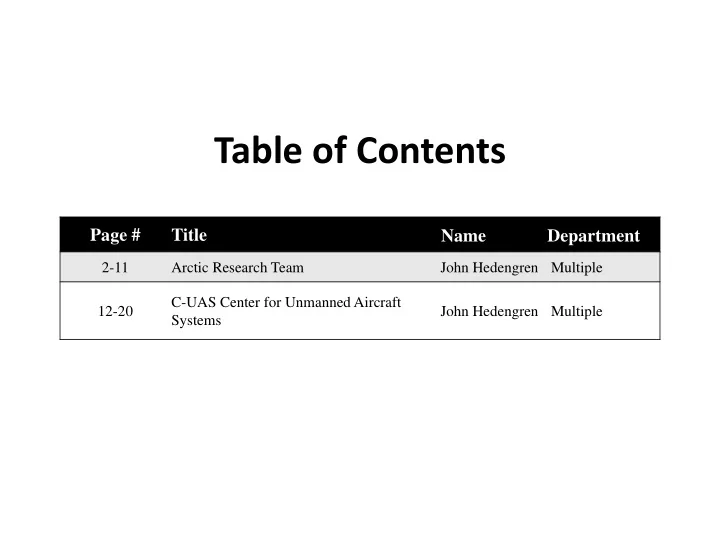

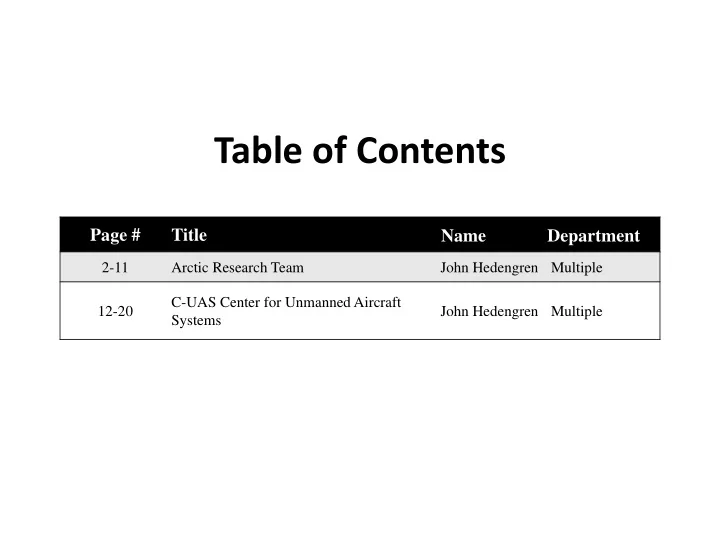

Table of Contents Page # Title Name Department 2-11 Arctic Research Team John Hedengren Multiple C-UAS Center for Unmanned Aircraft 12-20 John Hedengren Multiple Systems

Proposed Arctic Research Center John Hedengren Conrad Monson Chemical Engineering Research Development john_hedengren@byu.edu conrad_monson@byu.edu (801) 422 ‐ 2590 (801) 422 ‐ 2674 Research and Development Challenges: Composite materials to reduce riser weight and efficiency • High ‐ performance computing and advancements in • software and analytics to find oil and gas Better imaging to find resources in deepwater • Better understanding of environmental impacts • Greater reliability of subsea equipment •

John Hedengren and Conrad Monson Ira A. Fulton College of Engineering and Technology Brigham Young University 26 August 2013

• Estim ate 13% of the worlds undiscovered oil and 30% of its undiscovered natural gas 1 • Chulkchi Sea holds 15 billion barrels of recoverable oil and about 76 trillion cubic feet of recoverable natural gas 2 1 Unger, David. “White House Arctic strategy: What's next for oil, gas drilling?” Christian Science Monitor, May 13, 2013

“ We seek an Arctic region that is stable and free of conflict, where nations act responsibly in a spirit of trust and cooperation, and where economic and energy resources are developed in a sustainable manner that also respects the fragile environment and the interests and cultures of indigenous peoples (National Strategy for the Arctic Region, May 2013)”

• Statoil - tripled its Arctic research budget to $43.9 million in 2013 from some $14 million last year • ConocoPhillips - proposed to drill up to six exploration wells beginning in the summer of 2014 • Shell Oil - last year started exploratory drilling efforts

Statoil - despite spending $2M for • leases, the company is delaying and may abandon plans to drill ConocoPhillips - deferred drilling • until at least 2015; needs to address safety and other concerns raised by the Federal Government Shell Oil – last year’s exploratory • drilling efforts were plagued with The damaged Royal Shell Dutch drilling barge Kulluk technical problems and is loaded onto the transport ship XRK in Unalaska, Alaska. Unruly seas and severe storms plagued environmental and safety violations; exploratory oil and gas drilling in the Arctic last shell has to provide a plan to summer (Jim Paulin/AP/File) address concerns before it can drill again

Better oil spill preparedness Emergency preparedness cooperation among multiple operators that minimizes environmental impacts Length of time to get oil market after it is discovered (a decade or more) Potential environmental impacts to drilling Impacts from ice flow and overall freezing temperatures Short drilling season (July to October) in Chukchi and Beaufort Seas Strict government and tribal regulations Maintain infrastructure such as roads for drilling rigs Exxon Valdez Oil Spill

Composite materials to reduce riser weight and efficiency High-performance computing and advancements in software ScanEagle UAV and analytics to find oil and gas Better imaging to find resources in deepwater Better understanding of environmental impacts Greater reliability of subsea equipment

Math and Statistics Model/simulate operations in harsh conditions Calculate probability of ice occurrence Chemistry Research pollutants Develop enhanced measurement techniques for cold environments Geology Map and research the drilling impact of boulders and other sea floor features Mechanical engineering Analyze the behavior of structures (containment covers, tow lines, oil rigs, etc.) challenged by the harsh environment 1 from Shell report

Chemical Engineering Model vessels and/or oil rig usage Do research to help oil companies avoid permit violations Find better ways to provide propulsive power for oil and gas development with lower pollutions loads Business Address resource (including human) management issues Civil Engineering Measure salinity, temperature, etc. in the arctic ocean cold water column Anthropology Determine how to better work with the native tribes

Center for Unmanned Aircraft System Industry/University Cooperative Research Center Tim McLain Randy Beard Mechanical Engineering Electrical and Computer Engineering mclain@byu.edu beard@ee.byu.edu (801) 422 ‐ 6537 (801) 422 ‐ 8392 Program Objectives: Bring together university and industry researchers to • collaborate on research having industrial significance Explore new IR&D directions for industry • Solve problems of importance to industry • Provide training for next generation of industry leaders •

A National Science Foundation Industry/University Cooperative Research Center Tim McLain Randy Beard Brigham Young University

Presentation Outline • BYU UAS Research Overview • Center for Unmanned Aircraft Systems Overview

UAS Research at BYU • Cooperative timing problems • Cooperative persistent imaging Cooperative Control • Cooperative fire monitoring • Consensus seeking • 3D Waypoint path planning • Wind compensation Path Planning • Collision avoidance Trajectory Generation • Optic flow sensor • Laser ranger • EO cameras • Image stabilization Image Directed Control • Geo ‐ location • Vision ‐ aided tracking & engagement • Autopilot design for small UAVs • Attitude estimation Autonomous Vehicles • Adaptive control • Tailsitter guidance & control

Autonomous Flight For SUAS with SWPC Constraints Sensor Based Flight Applications • Optic Flow • Canyon following • Laser range finder • Collision avoidance • EO/IR • GPS denied navigation Applications Path Following • Precision Navigation • Robust to wind • Target tracking • Computationally • Target geo ‐ location efficient Kestrel Autopilot Technology Transition • Auto take ‐ off, land • Waypoint NAV • GPS guided 2004 2012

Guiding Objective Develop enhanced autonomous capabilities for small autonomous aircraft Develop and utilize: Novel custom sensors small light COTS sensors low cost Autonomy algorithms appropriate for computational resources Goal: Approximate large UAS capabilities with low ‐ cost, small UAS

NSF I/UCRC Program Overview • I/UCRC: Industry ‐ University Cooperative Research Centers Program • Objective: Bring together university and industry researchers to collaborate on research having industrial significance – Explore new IR&D directions for industry – Solve problems of importance to industry – Provide training for next generation of industry leaders

NSF I/UCRC Program Highlights • Established in 1980 • 56 centers, 156 sites currently • 754 industry memberships • Average of 18 industry members per center • Average of 4 universities per center • Average of 15 faculty scientists per center • Largest ‐ $12M, Mean ‐ $1.7M, Smallest ‐ $120K Well established, proven, highly successful program

Industrial Advisory Board Members • AFRL Aerospace Systems Directorate • AFRL Munitions Directorate • AAI ‐ Textron • BP • Boeing • Insitu • L ‐ 3 Communications • NASA Dryden Flight Research Center • National Oceanic and Atmospheric Administration • Northrop Grumman • United Technologies Research Center • Utopia Compression • Strong interest from: USBR, USACE, Lockheed Martin Several others being actively recruited and close to joining

Recommend

More recommend