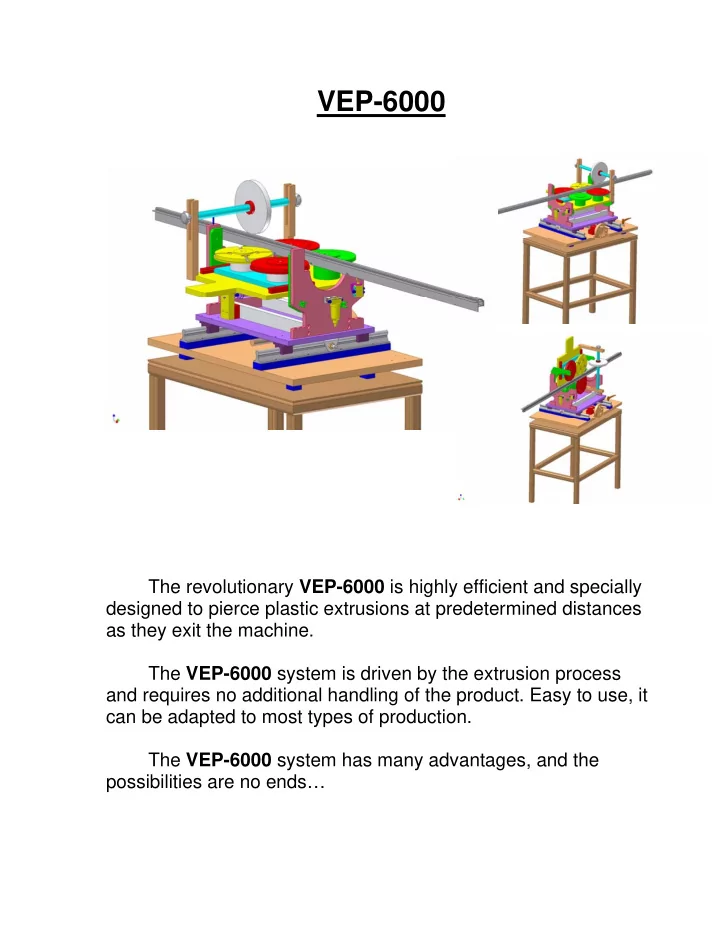

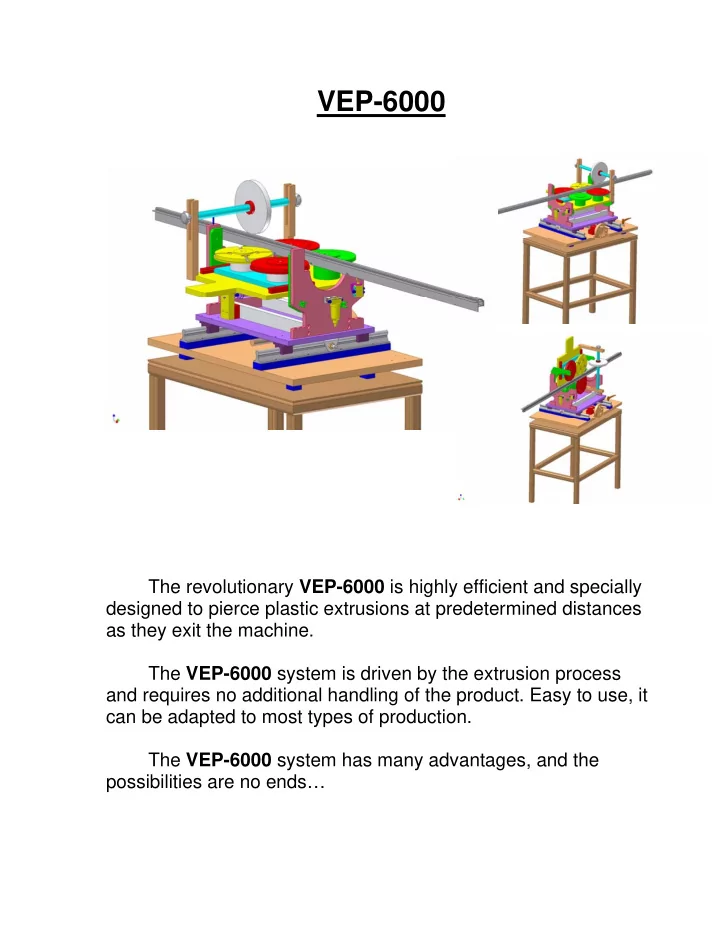

VEP-6000 The revolutionary VEP-6000 is highly efficient and specially designed to pierce plastic extrusions at predetermined distances as they exit the machine. The VEP-6000 system is driven by the extrusion process and requires no additional handling of the product. Easy to use, it can be adapted to most types of production. The VEP-6000 system has many advantages, and the possibilities are no ends…

There is a possibility of alignment between the VEP-6000 and the extruder in a ± 7.5º setting. In minutes, you will have your system aligned with the extruder because of the lineal adjustable handle. No more endless accuracy work for the tooling table to be aligned at the right spot of the extruder release. With this new system, all you need is to place the table at the extruder exit and proceed with the necessary adjustments to start the operation; all this in minutes!

Whith the transversal adjustment of 6’’ work line, you are sure to succeed in a perfect alignment between the VEP-6000 and the extruder and this, without any complicated and expensive positioning. Everything has been designed in a manner that your employees will be able to set up the machine in no time with a simple and secure procedure.

You will have the possibility to pierce holes at 90º with a fast and efficient setting, which will permit you to change profile in the extruder without changing the tooling. With simple settings, the VEP-6000 can work for you.

Recommend

More recommend