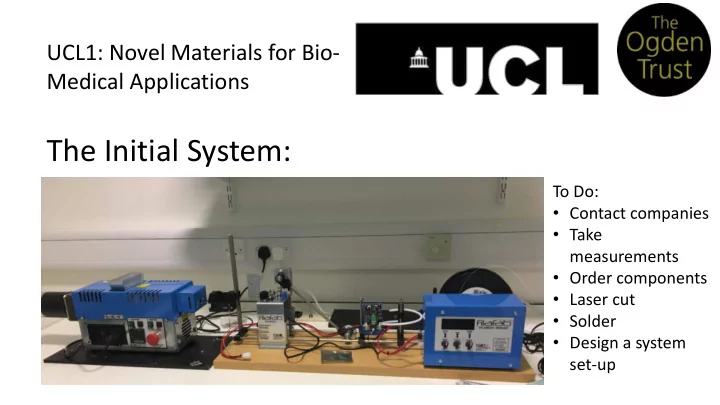

UCL1: Novel Materials for Bio- Medical Applications The Initial System: To Do: • Contact companies • Take measurements • Order components • Laser cut • Solder • Design a system set-up

The Updated System • Longer distance to extrude along • All components are level • Sturdy & fixed • Protected • Fancy

Thomas Sanladerer Filament Diameter Sensor Uses a Hall sensor & magnet pairing to detect magnetic fields and convert to potential differences. This is converted to ADC input via the Arduino which can be calibrated within the sketch (right column indicates diameter in millimetres). There is some magnetic interference causing noise to effect the outputs, my next step is to develop something to cancel this out.

The clear colorfabb_XT filament below indicated that there were a lot of air pockets My First Filaments: in my filaments which could cause issues when trying to print. The next step in my development of this system was to reduce the air pockets as far as possible & create filaments of consistent diameters.

Improving the quality of filaments I extruded the colorfabb_XT filaments To improve consistency in To improve the quality further I’d propose again at 200 degrees Celsius rather that we remove an element of the extruder filament diameter, it would be than 240 degrees Celsius I had used that prevents the raw granules from entering beneficial to develop a casing for previously. This allowed for a much the diameter sensor which the Auger screw at an even distribution. slower extrusion speed. This I’d also suggest a more narrow hopper to reduces noise in the readings by immediately resulted in a drop in the cancelling out interfering prevent granules from sitting at the sides of number of air pockets. the entrance. magnetic fields.

My Recycled Filament I made a filament using 50% failed prints and 50% PLA granules. I was only able to attempt this once before the end of my internship but I saw a big potential in making filaments from recycled materials using this set-up. Issues arose from the uneven distribution of the materials, resulting in a slow extrusion, discoloration and uneven surfaces. However, with a few adjustments to the hopper, where materials are funnelled into the extruder, I think this could make a big impact on the waste involved with 3D printing plastics.

Public Engagement • Teaching Year 8 boys about Ultrasound • Teaching Year 2 children about 3D printing & organs in the body • Speaking with school-children enabled us to question what they thought it meant to be a scientist. Q: What is a scientist? A: Curious, respectful, resilient • Breaking stereotypes allows students to view science as a possible pathway for themselves; rather than a job done by adult men in lab coats.

Attending workshops & workplace events: • Frugal innovation workshop with Dr Prashant Jha • WEISS away day • UCH nurses training Workshop: learnt about how medical issues can be solved at low costs to increase accessibility & pitched our own solutions to common issues. Also learnt about the opportunity to work for Dr Prashant Jha as an intern in San Francisco. Away day: observed the achievements of WEISS in the past year & spoke to members about their own journeys. This gave me some ideas what I would like to do after graduating. Training: learnt about PCNL kidney stone removal & the tools/technology uses to do so.

Kidney Phantom for PA Imaging Below is the set-up used to mix the material used to print the phantom. We used gel wax, glass microspheres, titanium oxide and optional dye. We used a hand mixer, a sonicator and a de-gas chamber to mix on a particle level and remove air pockets. (left) First model printed, over-extruded and too much carbon black dye in healthy material. (right) The completed half shell kidney print using the Wel Gax printer. The second model was good and we were able to scan it and confirm the mixture for the healthy & unhealthy tissue were suitable for PA imaging. However, the model was under-extruded so we printed again to create a whole model without gaps for the internal structure. We planned to then print another model with the internal structure made from a material with contrast somewhere between the healthy & unhealthy tissue.

First Photoacoustic Image Second Photoacoustic Image The healthy tissue composition was the same as the We used glass microspheres, titanium oxide & carbon black unhealthy but had much less carbon black dye. When dye for the unhealthy tissue in both models (red shapes in both images). The first scan showed that our healthy tissue making the second model we didn’t use dye and the results were much better. We were told to fill the internal structure was too attenuating and we needed to change the material composition. with a material in-between the healthy and unhealthy tissue to give a contrast & detail in the scan.

We improved the extrusion rate by increasing the heat bath. This The final imaging session we did Third Kidney Model reduced the air holes in the model showed a nice contract between the making it much more suitable for external and internal structure. photoacoustic imaging. However, the unhealthy tissue We filled the internal structure with blended too much with the internal a material in-between the healthy structure and we were advised to & unhealthy tissue; adding some make the tissue using much more unhealthy tissue into a pocket. dye. This is something we will pass on to those continuing with the project.

A big thank you to Ogden Trust, Daniil, Guy & Karol for making my 8 week internship at UCL not only possible but also unforgettable in the best of ways! The people I’ve met & the tasks I’ve been set have inspired me even more to pursue a career in medical physics & research.

Recommend

More recommend