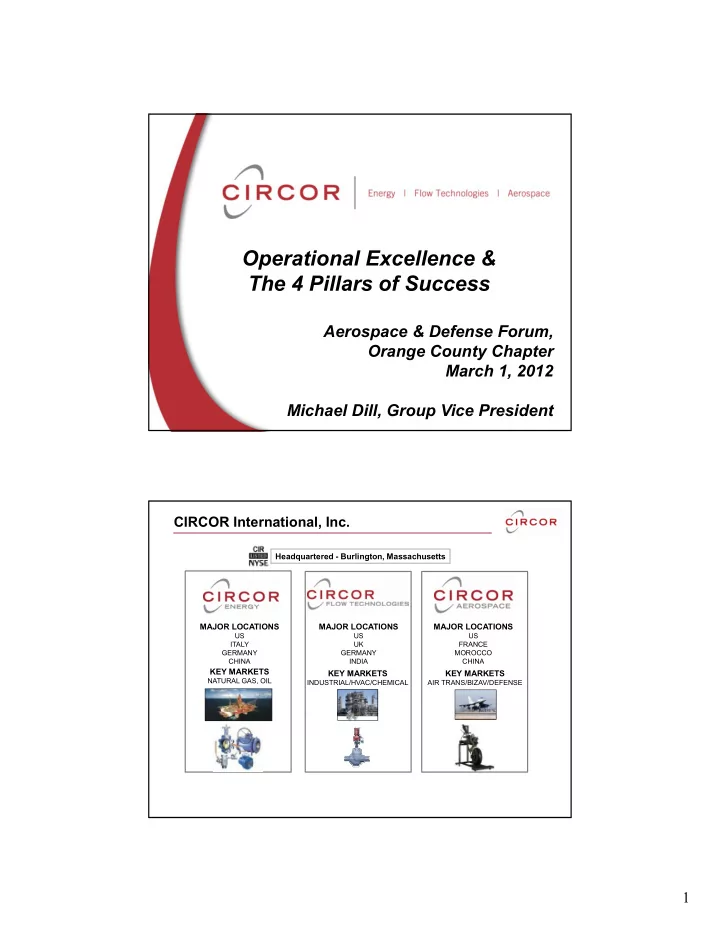

Operational Excellence & The 4 Pillars of Success Aerospace & Defense Forum, & f Orange County Chapter March 1, 2012 Michael Dill, Group Vice President CIRCOR International, Inc. Headquartered - Burlington, Massachusetts MAJOR LOCATIONS MAJOR LOCATIONS MAJOR LOCATIONS US US US ITALY UK FRANCE GERMANY GERMANY MOROCCO CHINA INDIA CHINA KEY MARKETS KEY MARKETS KEY MARKETS NATURAL GAS, OIL INDUSTRIAL/HVAC/CHEMICAL AIR TRANS/BIZAV/DEFENSE 1

Group Structure CIRCOR North America and Europe Aerospace Products Group (900 + Employees Worldwide) Landing Gear / Fluid Control Electromechanical Control Actuation Systems Group Headquarters Paris, FRANCE 6 Mfg., Sales and Sylmar, California Pau, FRANCE Service Sites Dayton, Ohio Chemille, FRANCE Corona, California 2 Low Cost Mfg Sites Hauppauge , New York Tangiers, MOROCCO Suzhou, CHINA Engineering + HCL partnership HCL partnership “One CIRCOR Aerospace” “One CIRCOR Aerospace” ‐ ‐ Building the Brand with an Building the Brand with an Integrated, Global Footprint Integrated, Global Footprint 3 2011 Sales Estimate Sales By Segment Sales By Region Medical Other Business 7% Misc. Global 3% 3% Aviation 6% EMEA 42% Military OEM NA 50% Commercial 37% Aftermarket 6% Commercial Commercial Air Transport Military OEM LA 1% Spares 8% 37% Electromechanical Control 16% Fluid Control Systems Landing Gear 53% Systems 31% 31% Sales By Product Line Overall Business Balance Improving with Sylmar Acquisition Overall Business Balance Improving with Sylmar Acquisition and Key 2011 Wins and Key 2011 Wins 4 2

Harnessing The Power of Proven Industry Innovators Bringing together proven innovative capabilities of industry leading brands… …to develop and deploy the precision solutions… to develop and deploy the precision solutions …necessary for our customers to succeed – and continue to partner with us Bringing together proven industry innovators into one brand, one image, one aerospace company 5 Major Programs – Commercial Aircraft, Defense Aircraft/Rotorcraft/UAV, Regional Air Transport, Business Jets Airbus A350 XWB , A330/340 Boeing Next Generation: 737, 747, 767 and 777 Mitsubishi Regional Jet / Bombardier Regional Jet Gulfstream 650/Learjet 85/Hawker Beechcraft/Dassault 7X, 2000/ Cessna Citation / BBJ / Hondajet / Embraer Phenom/Bombardier Global Express T ‐ 38 / T ‐ 45 / F ‐ 15 / F ‐ 16 / F ‐ 18 / F ‐ 22 /F ‐ 35 UAVs: Predator / Global Hawk / Fire Scout CH ‐ 47 / Augusta Westland 129 BCH Helicopter / AH ‐ 64D / Eurocopter EC ‐ 175 (Z ‐ 15) Sikorsky UH ‐ 60 Black Hawk 3

Product Portfolio Actuation Electro-Mechanical Sub-Systems Components Fluidic Landing Gear Control Control Air Transport Regional Business Aviation Military Fix Wing Military Rotorcraft Unmanned Aircraft Growth = Creating Customer/Shareholder Value Strategy � Expand commercial and aftermarket business � Invest in engineering and proprietary products � Develop sub ‐ system integration capability Design to Spec D i t S � Partner with Tier 1 system providers � Win major, long ‐ term growth platforms with customer performance � Acquire complementary technologies for Value critical controls and landing gear solutions Build to Print Machining 8 4

Low Cost Sourcing Strategy China – Suzhou � Machining / Final Assy / Test � Local supply chain Morocco - Tangier � Assy & Test � Machining � Windings India - Coimbatore � Engineering + HCL partnership � Sourcing components � Future potential: Assy, machining CIRCOR Ownership of Low Cost Facilities is a Key Value CIRCOR Ownership of Low Cost Facilities is a Key Value Proposition for our Customers Proposition for our Customers 9 OUR VISION . . . THE CIRCOR BUSINESS SYSTEM (CBS) TALENT SUSTAINED PROFITIBILITY IMPROVED EXPLOIT NEW OPERATIONAL CULTURE ACQUISITON & COMPETITIVE & ASSET STAKEHOLDER OPPORTUNITIES EXCELLENCE DEVELOPMENT ADVANTAGE VELOCITY VALUE • Talent • Leadership • Continuous • Cash • Acquisitions • Values Improvement p Generation • Growth Gro th • Engaged E d • New Markets N M k t • Behaviors • Speed & • ROIC Employees • New Products • Customer • Brand Flexibility Loyalty • Employment Identity Branding • Repeatable & • Customer Reliable Lean • Careers Focus Processes Product Innovation Customer Relationship Development Global Business & Supply Chain Development pp y p Acquisition Integration & Repositioning Talent Acquisition, Development & Retention Lean Enterprise, Six Sigma & Continuous Improvement 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 5

CIRCOR’s Operational Excellence Model � Applying Lean “an inch wide and a mile deep” – focus efforts, gain success, and increase impact to the corporation. – Must be Measurable!!! � Ten Steps to a Model Line – Modeled after proven methodologies – 12-18 month process – Multi-Tiered (Continuous Improvement) – Internally Developed Training/Tools – Cross Corporation Sharing – Model Cells � Operational Excellence Leadership Team – Roadmap/Vision Roadmap/Vision – Standards – Educational Tools � CIRCOR Problem Solving – Basic Problem Solving Education – Structured Certification Process – Advanced Course 11 MODEL LINE Approach CIRCOR Business System 4 Value Stream Performance Gold levels World Class Performance 3 Silver Value Stream Linked From Customer through Factory to Lean Enterprise Supply Chain 2 Bronze Completion of CBS-Ten Steps to make a Value Stream Lean (Inside the 4 walls) 1 Stability – Lean Fundamentals No “hockey stick”, lean thinking “critical mass”, robust kaizen activity, basic lean training accomplished 12 6

10 Step Process Communication 13 We were still missing something……. 14 7

Marrying Culture and Op-Ex Business Results 4 Pillars Gaps to Culture of Excellence Excellence THE THE O Operational ti l The Base CIRCOR BUSINESS SYSTEM Excellence (CBS) 4 Pillars of Future Excellence 16 8

Pillar 1: Customer Satisfaction Relentless Pursuit of Customer Satisfaction � We must make it a part of our DNA � We must make it a part of our DNA � Should permeate through all levels � Messaging, measurement, process, tools � Goes well beyond Delivery and Quality Performance Performance 17 Pillar 2: New Product Introduction Best in Class New Product Introduction � Process/skillset/people/discipline � Process/skillset/people/discipline � “We are an engineering company that manufactures, not a manufacturing company with engineering capabilities” � Migraton; Mfg – BTP to Increased BTS � Critical to Strategy – Tier 1 Design Partner � It is a Whole Business Process 18 9

Pillar 3: Great Place to Work CIRCOR a great place to work at all levels � Attraction � Attraction - Retention - the best people…. Retention the best people � Our people as a competitive weapon � Leadership must create the environment: � Empowerment leads to … � Engagement … � Ownership… � Passion… � Passion � Performance TURN IT LOOSE!!! 19 Pillar 4: Leadership Leadership Team with few equals � First Class Tone at the top � Value driven, we do things right g g � Brave and Decisive yet data driven � Performance Orientation � Pure: open/honest/no fear of expression of opinion � Drivers of continuous improvement across enterprise � Passionate about new leader development � Continuing Education is way of life � Leaders of the Culture Change 20 10

CIRCOR Aerospace Success � CH47 Landing Gear Line Achieved Bronze Certification – Lead-time Reduction from 18 months to 1 Month – Floor Space Reduction of 80% – Single Point of Schedule and Single Piece Flow through two facilities Single Point of Schedule and Single Piece Flow through two facilities – 21% cost Reduction – All flow on Pull of Customer – 3 Years without a missed delivery � Benchmarked by Multiple Leading Customers � Won Sikorsky Blackhawk Landing Gear – And all major programs targeted +$200 million in 2011 � 4 Additional Model Lines Launched in 2011/2012 – Fluid Control, Corona – A350, France – Landing Gear Sylmar – JSF Pneumatic Launch Modules 21 Corona F-16, CH-47 Cells & A350 Test Lab Before After 22 11

Corona Machine Shop Progress toward future state Market Cell – holding stock at various of WIP & Finished Goods 23 CIRCOR Industria – A350 Cell “before” 24 12

CIRCOR Industria – A350 Cell progress 25 CIRCOR Industria – A350 Cell “after” 26 13

Long Island Facility Move & Upgrade 27 Sylmar Pre-work for overhaul “Future State” 28 14

Lean Benchmarking “I will say on behalf of the Messier ‐ Bugatti staff that we were very impressed with your facility and operations. It truly demonstrated what is possible with the correct lean perspective. You should be proud of what you are doing and it is evident that you are Thank you very much evident that you are. Thank you very much for the opportunity to be a witness to your success.” – Mike Michele, Operations and Supply Chain Manager ‐ Wheels and Brakes, Messier ‐ Bugatti USA Moving OpX Excellence Beyond MFG � 12 Global NPI Kaizens in 2011 +30% of Kaizens scheduled in 2012 are Transactional � � Engagement of Front Office/Back Office � Expanded CIRCOR Problem Solving to include Advanced training January 11- Planning/Scheduling Kaizen Team 30 15

Recommend

More recommend