Parker Eaton, Tyler Bowes, Preston Cecil, Haleigh Tucker BOATY MCFLOATY FEDD 2016

Research • Focused on the general composition and utility of concrete structures • Main objective geared toward methods of reinforcement and processes of mixing and curing cement • Found that greater water-cement ratio leads to greater air entrainment • Adding variety of chemical admixtures to cement increases durability and water resistance • Proper curing allows cement to retain sufficient hydration before hardening (prevents shrinking/cracking) • Providing reinforcements for the cement while drying is critical to maintaining desired structure

Materials • Glass microspheres • Aluminum powder • Quikrete • Plastic cups and forks • Plywood (for base) • Trash bags • Insulation Foam • Hot glue • Concrete bonder • Gloves • Plastic Wrap • Paper Towels

Foam Mold • Purchased 1x24 sheet of insulation foam • Cut foam into shaped pieces and hot glued layers on top of each other • Sanded mold by hand into final curved shaped • Finished by joining two halves of mold with glue • Also built wooden mixing box in craft center woodshop

Construction of Boaty McSinky Equation: 58% Quikrete, 20% glass • microspheres, 16%water, and 6% air 2 Liters total worth of mix • Covered foam mold with trash bag prior to • application of cement Scooped Quikrete into plastic cups and • pulled out larger pieces of gravel Poured concrete powder into wooden • mixing box Added concrete binding liquid, aluminum • powder, and glass microspheres into wooden box—mixed with plastic forks Used gloves and forks to coat mold with • cement Repeated application three times, • attempting to smooth layers and prevent holes in structure

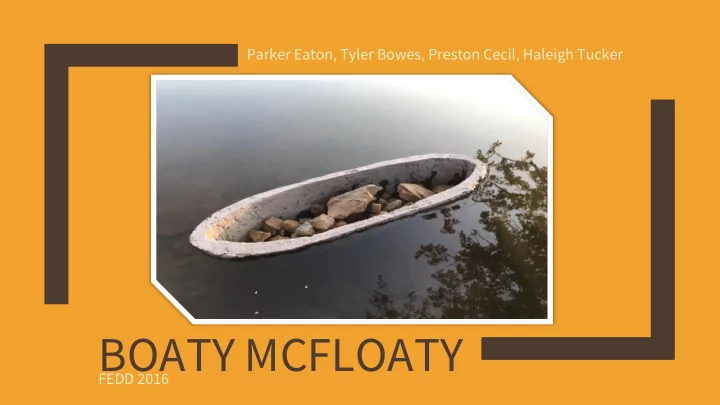

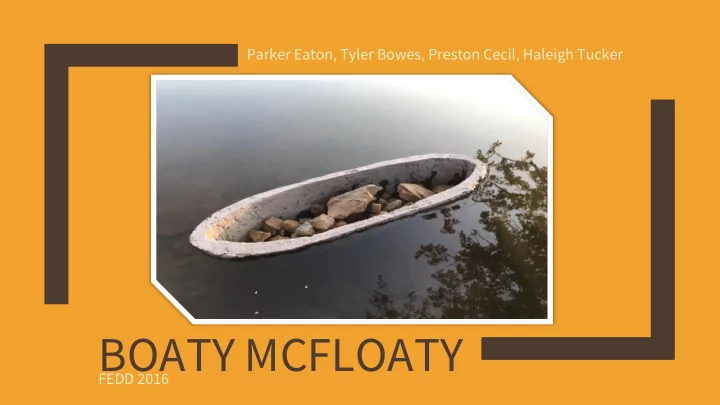

Results of First Iteration • Layering cement in multiple layers caused canoe to take on water • Flimsy structure created cracks • Canoe shattered after sinking and hitting a rock • Addition of aluminum powder may have widened pores—increasing likelihood of developing holes • Required team to go back to the drawing board • Cured with wet paper towels, which were less capable of retaining moisture • Outer structure was not smooth • Failure to construct a foam mold using the Garage Shopbot prolonged construction process

Second Iteration Modified plastic cups to sift out Quikrete • powder and remove gravel more efficiently Eliminated aluminum powder from list of • aggregates added Mixed all cement in one bath instead of • applying the four layers separately Cured twice daily for a period of one week • by sprinkling with water and covering with cling wrap to retain moisture for longer periods of time Sanded Interior and exterior to smoothen • texture Tested Boaty McFloaty II in Lake Raleigh on • Centennial Campus– it didn’t sink!

Conclusion • Errors with “Boaty McSinky” required all members of the team to consider the Engineering Design Cycle and resolve problems through critical thinking • Learned the importance of preserving resources in case of disaster—taught team members the importance of preparing for failure • Exploration of resources and facilities aided the construction of the canoe and prevented team from going over budget • Each team member contributed their unique skills and talents to promote the project overall

Recommend

More recommend