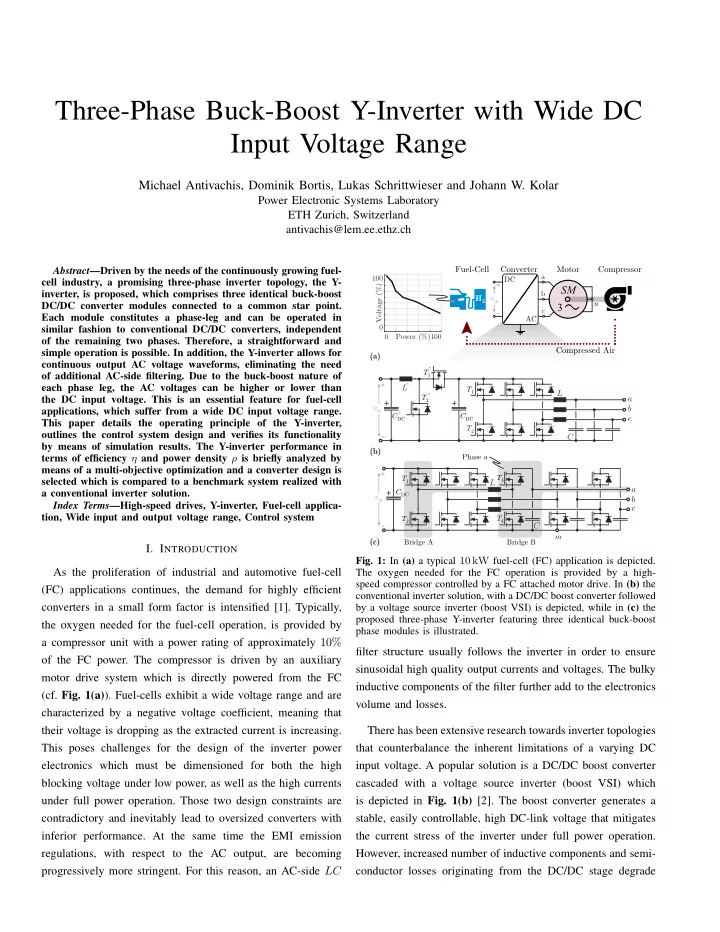

Three-Phase Buck-Boost Y-Inverter with Wide DC Input Voltage Range Michael Antivachis, Dominik Bortis, Lukas Schrittwieser and Johann W. Kolar Power Electronic Systems Laboratory ETH Zurich, Switzerland antivachis@lem.ee.ethz.ch Fuel-Cell Converter Motor Compressor Abstract —Driven by the needs of the continuously growing fuel- a 100 DC cell industry, a promising three-phase inverter topology, the Y- Voltage (%) SM inverter, is proposed, which comprises three identical buck-boost b H 2 v in n DC/DC converter modules connected to a common star point. 3 c Each module constitutes a phase-leg and can be operated in AC 0 similar fashion to conventional DC/DC converters, independent 0 Power (%) 100 of the remaining two phases. Therefore, a straightforward and Compressed Air simple operation is possible. In addition, the Y-inverter allows for (a) continuous output AC voltage waveforms, eliminating the need ‘ T 1 of additional AC-side filtering. Due to the buck-boost nature of ‘ each phase leg, the AC voltages can be higher or lower than L T 1 ‘ L T 2 a the DC input voltage. This is an essential feature for fuel-cell + + v in b ‘ applications, which suffer from a wide DC input voltage range. C DC C DC c This paper details the operating principle of the Y-inverter, T 2 outlines the control system design and verifies its functionality C by means of simulation results. The Y-inverter performance in (b) terms of efficiency η and power density ρ is briefly analyzed by Phase a means of a multi-objective optimization and a converter design is T 3 T 1 selected which is compared to a benchmark system realized with L a a conventional inverter solution. + C DC v in b Index Terms —High-speed drives, Y-inverter, Fuel-cell applica- c tion, Wide input and output voltage range, Control system T 2 T 4 C m (c) Bridge A Bridge B I. I NTRODUCTION Fig. 1: In (a) a typical 10 kW fuel-cell (FC) application is depicted. As the proliferation of industrial and automotive fuel-cell The oxygen needed for the FC operation is provided by a high- speed compressor controlled by a FC attached motor drive. In (b) the (FC) applications continues, the demand for highly efficient conventional inverter solution, with a DC/DC boost converter followed converters in a small form factor is intensified [1]. Typically, by a voltage source inverter (boost VSI) is depicted, while in (c) the proposed three-phase Y-inverter featuring three identical buck-boost the oxygen needed for the fuel-cell operation, is provided by phase modules is illustrated. a compressor unit with a power rating of approximately 10% filter structure usually follows the inverter in order to ensure of the FC power. The compressor is driven by an auxiliary sinusoidal high quality output currents and voltages. The bulky motor drive system which is directly powered from the FC inductive components of the filter further add to the electronics (cf. Fig. 1(a) ). Fuel-cells exhibit a wide voltage range and are volume and losses. characterized by a negative voltage coefficient, meaning that their voltage is dropping as the extracted current is increasing. There has been extensive research towards inverter topologies This poses challenges for the design of the inverter power that counterbalance the inherent limitations of a varying DC electronics which must be dimensioned for both the high input voltage. A popular solution is a DC/DC boost converter blocking voltage under low power, as well as the high currents cascaded with a voltage source inverter (boost VSI) which under full power operation. Those two design constraints are is depicted in Fig. 1(b) [2]. The boost converter generates a contradictory and inevitably lead to oversized converters with stable, easily controllable, high DC-link voltage that mitigates inferior performance. At the same time the EMI emission the current stress of the inverter under full power operation. regulations, with respect to the AC output, are becoming However, increased number of inductive components and semi- progressively more stringent. For this reason, an AC-side LC conductor losses originating from the DC/DC stage degrade

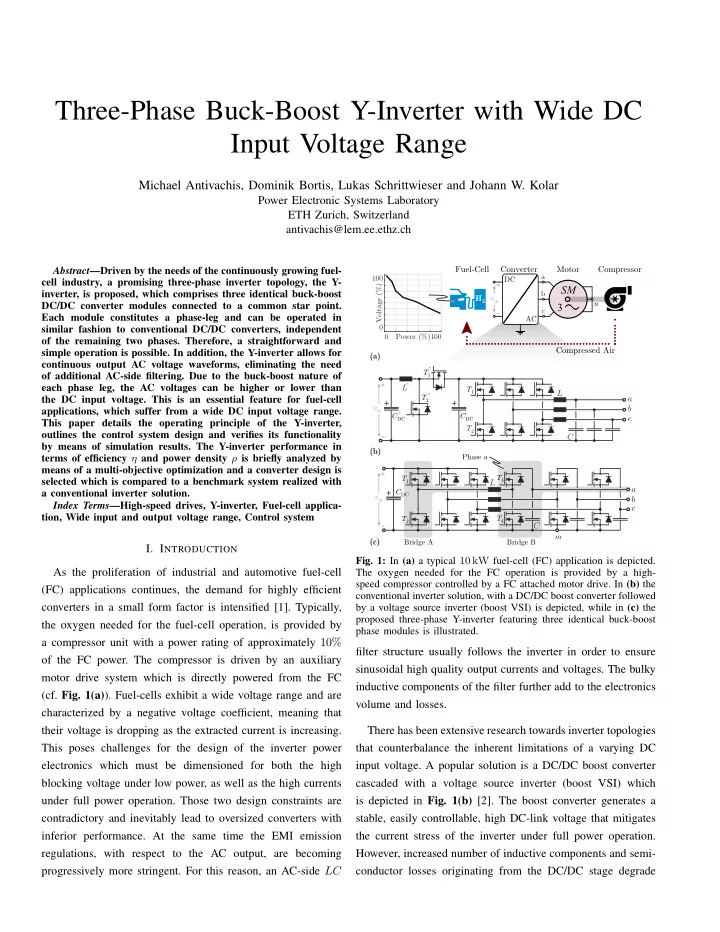

i in i a c b 1 a ˆ U o u an u bn u cn T 1 T 3 Machine Voltage i La + Duty Cycles L u in u am A B d A C 0 0.5 d B T 2 T 4 m Buck Boost (a.i) ˆ Bridge Bridge - U o i a 0 a (b) 0 T o /2 T o (d) 0 T o /2 T o T 1 T 3 Time Time i La + L 2 ∆I L,Pk u in u am ˆ C ˆ 2 I o 2 U o Boost u am T 2 T 4 U in i La Terminal Voltage ˆ I o (a.ii) m U in Current i a ˆ 0 a U o T 1 T 3 u off Buck ˆ - I o L i La + u in v am i a C ˆ 0 -2 I o T 2 T 4 (c) (e) 0 Time T o /2 T o 0 Time T o /2 T o m Boost Buck Boost Buck (a.iii) Fig. 2: Operating principle of the Y-inverter. In (a.i) one of the three identical bridge-leg modules comprised in the Y-inverter is depicted. In (a.ii) and (a.iii) the boost and buck operation are highlighted respectively. In (b) the three AC motor voltages voltages are illustrated while in (c) the corresponding strictly positive terminal inverter output voltage of phase a is depicted. The required buck d A and boost d B duty cycles are presented in (d) and the inductor current i La is plotted on top of the motor AC current i a in (e) . TABLE I: Y-inverter fundamental quantities. the overall system performance. Alternative single conversion Parameter Buck Operation Boost Operation stage topologies, such as the Z-source inverter, have gained ≤ U in ≥ U in u am significant interest over the past decade [3] [4]. The Z-source u am ( t ) d A ∈ [0 ... 1] 1 inverter utilizes a unique impedance network and shoot-through U in U in 1 u am ( t ) ∈ [0 ... 1] d B zero states to boost the voltage of the capacitors of the Z-source Switch signals T 1 on : d A > Car T 1 on network, but suffers from increased voltage stress under high T 2 on : d A < Car T 2 off boost ratios. T 3 on T 3 on : d B > Car T 4 off T 4 on : d B < Car In response to these shortcomings, an inverter module, ref- u A d A U in U in erenced to as Y-inverter (cf. Fig. 1(c) ), is presented within u B u am d B u am this paper. Based on the well established idea of realizing a 1 u am d A U in d B U in three-phase inverter by connecting three DC/DC converters to 1 Low freq. ind. i a d B i a a common star point [5]–[10], three identical phase modules current � i La � d A (1 − d A ) U in d B (1 − d B ) u am 1 1 are attached to the negative DC-rail m . The Y-inverter benefits ∆ I L,Pk 2 2 f s L f s L from three key features. Firstly, each phase-leg can employ of simulation results. Sec. IV is dedicated to the selection of the simple controllers similar to conventional DC/DC converters. hardware demonstrator and the critical design aspects. Finally, Secondly, the Y-inverter provides a continuous AC output the conclusions are drawn in Sec. V . voltage which eliminates the need of a dedicated output filter. II. O PERATION P RINCIPLE Finally, due to its buck-boost characteristic, the DC input voltage can be higher or lower than the AC voltage. The Y-inverter, presented in Fig. 1(c) , consists of three In this paper, in a first step the operating principle of the identical phase-legs: Each phase is comprised of two half Y-inverter is explained in Sec. II . An appropriate control bridges connected to the opposite terminals of an inductor L , scheme in introduced in Sec. III while the seamless and and an output capacitance C placed between the AC output uncomplicated operation of the Y-inverter is verified by means terminal a, b, c and the negative DC-rail m , which forms a

Recommend

More recommend