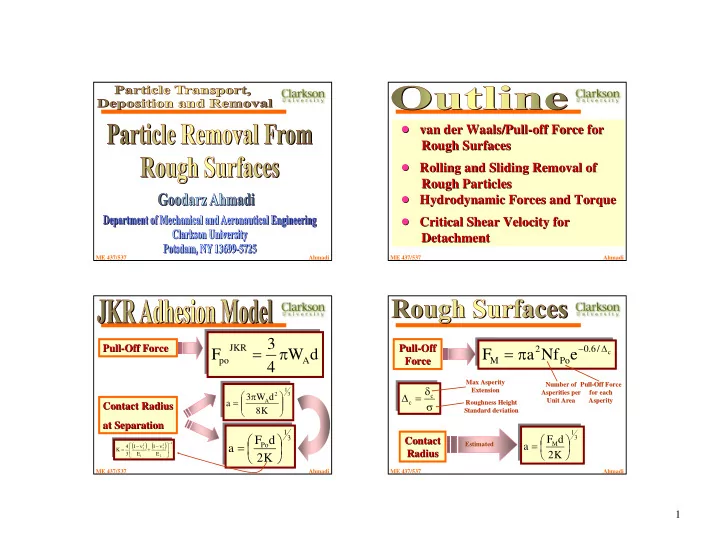

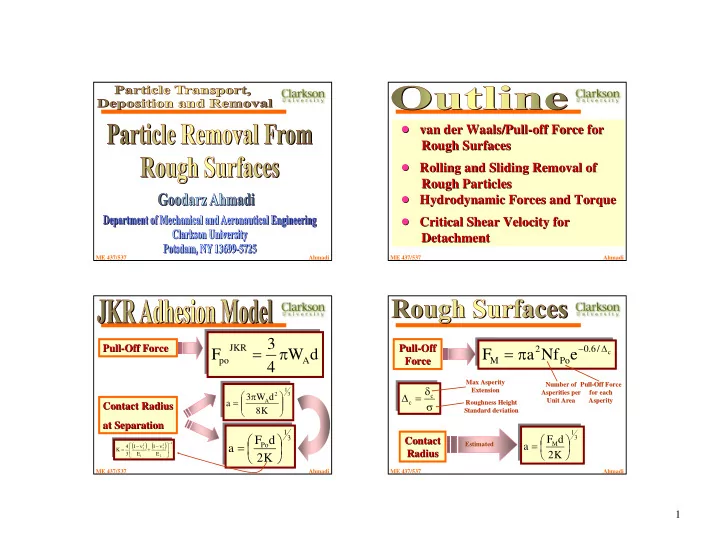

! van ! van der der Waals Waals/Pull /Pull- -off Force for off Force for Rough Surfaces Rough Surfaces ! Rolling and Sliding Removal of ! Rolling and Sliding Removal of Rough Particles Rough Particles ! Hydrodynamic Forces and Torque ! Hydrodynamic Forces and Torque ! Critical Shear Velocity for ! Critical Shear Velocity for Detachment Detachment ME 437/537 Ahmadi ME 437/537 Ahmadi 3 − ∆ = π = π Pull- -Off Force Off Force JKR Pull- -Off Off Pull Pull 2 0 . 6 / F W d F a Nf e c po A Force M Po Force 4 Max Asperity Max Asperity Number of Number of Pull Pull- -Off Force Off Force δ 1 Extension Extension ⎛ π ⎞ Asperities per for each ∆ = Asperities per for each 2 3 3 W d c = ⎜ ⎟ Unit Area Unit Area Asperity Asperity A a σ Roughness Height ⎜ ⎟ c Roughness Height Contact Radius Contact Radius ⎝ ⎠ 8 K Standard deviation Standard deviation at Separation at Separation 1 1 ⎛ ⎞ ⎛ ⎞ F d 3 F d 3 Contact Contact = ( ) ( ) = ⎜ ⎟ ⎜ ⎟ − Estimated M ⎡ − ν − ν ⎤ 1 Po a 2 2 a 4 1 1 = + 1 2 K ⎢ ⎥ ⎝ ⎠ Radius Radius ⎝ ⎠ 2 K ⎣ ⎦ 3 E E 2 K 1 2 ME 437/537 Ahmadi ME 437/537 Ahmadi 1

Equilibrium Separation Distance Equilibrium Separation Distance 1 / 3 ⎡ ⎤ 2 JKR f JKR δ = Po ⎢ ⎥ Model Model β c 2 ⎣ ⎦ 3 K Greenwood- - Greenwood σβ N ≈ 0.1 Williamson Williamson Average Roughness Height Average Roughness Height Displaced Origin of Velocity Profile Displaced Origin of Velocity Profile = 5.9 σ e = k r 0.53k r ME 437/537 Ahmadi ME 437/537 Ahmadi π µ 3 f d + + = = u y F V Drag Force Drag Force t C c + = − β + + ≤ 2 v y , y 1 . 85 ( ) dV / dy = ρµ 1 / 2 2 o F 1 . 61 d V Lift Force Lift Force l 1 / 2 dV / dy + = β + + w 2 y z o πµ 2 2 f d V = Hydrodynamic Hydrodynamic m M β o = t 0 . 01085 Torque Torque C c ME 437/537 Ahmadi ME 437/537 Ahmadi 2

πρ * 2 5 . 8 du L + = Drag Force d Drag Force F + = + σ + + + − α + = + u 2 . 76 H L t C 0 2 ρ 2 * 3 1 . 95 d u L Λ + + = Lift Force d Lift Force F + = β + σ + + + − α + w ( 2 . 76 H ) ν L 0 2 2 πρ * 2 2 2 . 14 u d L Hydrodynamic Hydrodynamic d = = + σ + − α M L 2 . 76 H 0 Torque Torque t 2 C ME 437/537 Ahmadi ME 437/537 Ahmadi F l F M l t M t F d / 2 t d F mg t mg L O a a F a F M ME 437/537 Ahmadi ME 437/537 Ahmadi 3

MOMENT DETACHMENT MOMENT DETACHMENT 1 / 2 ⎡ ⎤ ⎢ ⎥ π − ∆ + 2 2 aC [ a Nf exp[ 0 . 6 /( ) ] mg ] = Rolling * ⎢ po c ⎥ Rolling u c d * ⎢ aCu ⎥ + − α + − ≥ ρ π + 2 c M F ( ) ( F mg ) a F a Ld ( 5 . 04 1 . 95 ) ⎢ ⎥ ⎣ ν ⎦ t t 0 L M 2 1 / 2 ⎡ ⎤ ⎢ ⎥ π − + 2 2 kC [ a Nf exp[ 0 . 6 /( D ) ] mg ] Sliding Sliding SLIDING DETACHMENT SLIDING DETACHMENT = ⎢ po c ⎥ * u . c * ⎢ kCdu ⎥ ρ π + c Ld ( 5 . 8 1 . 95 ) ⎢ ⎥ ν ≥ + − ⎣ ⎦ F k ( F mg F ) t M L ME 437/537 Ahmadi ME 437/537 Ahmadi Rolling Rolling ⎡ ⎤ 1 / 2 ( ) ⎢ ⎥ π − ∆ + 2 2 aC a Nf exp[ 0 . 6 /( ) ] mg ⎢ ⎥ = * po c u ⎢ ⎛ ⎞ ⎥ c * * * u L aCu u L ρ + ⎜ π + + ⎟ 2 1 / 2 ⎢ c c c ⎥ Ld ( 1 . 72 0 . 1 ) ⎜ 5 . 04 1 . 95 ( 1 . 72 0 . 2 ) ⎟ ν ν ν ⎝ ⎠ ⎣ ⎦ Sliding Sliding 1 / 2 ⎡ ⎤ ⎢ ⎥ π − ∆ + 2 2 kC [ a Nf exp[ 0 . 6 /( ) ] mg ] ⎢ ⎥ = * po c u ⎢ ⎛ ⎞ ⎥ c * * * u L kCdu u L ρ + ⎜ π + + ⎟ 1 / 2 ⎢ c c c ⎥ dL ( 1 . 72 0 . 1 ) ⎜ 5 . 8 1 . 95 ( 1 . 72 0 . 2 ) ⎟ ν ν ν ⎣ ⎝ ⎠ ⎦ ME 437/537 Ahmadi ME 437/537 Ahmadi 4

5 Ahmadi Ahmadi ME 437/537 ME 437/537 Ahmadi Ahmadi ME 437/537 ME 437/537

� Rolling detachment is the dominant mechanism � Rolling detachment is the dominant mechanism for detachment of rough spherical particles. for detachment of rough spherical particles. � Roughness significantly reduces the adhesion � Roughness significantly reduces the adhesion pull- -off force. off force. pull � Turbulence near wall flow structure plays an � Turbulence near wall flow structure plays an important role in particle detachment process. important role in particle detachment process. � Accounting for surface roughness improves the � Accounting for surface roughness improves the agreement between the model prediction and agreement between the model prediction and experimental data experimental data ME 437/537 Ahmadi ME 437/537 Ahmadi ME 437/537 Ahmadi 6

Recommend

More recommend