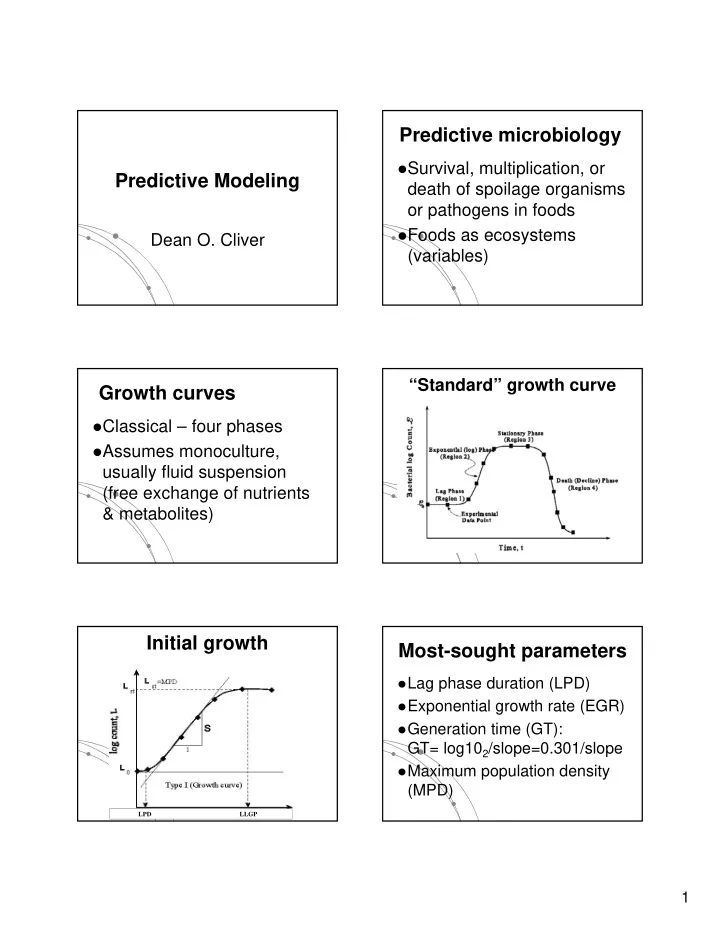

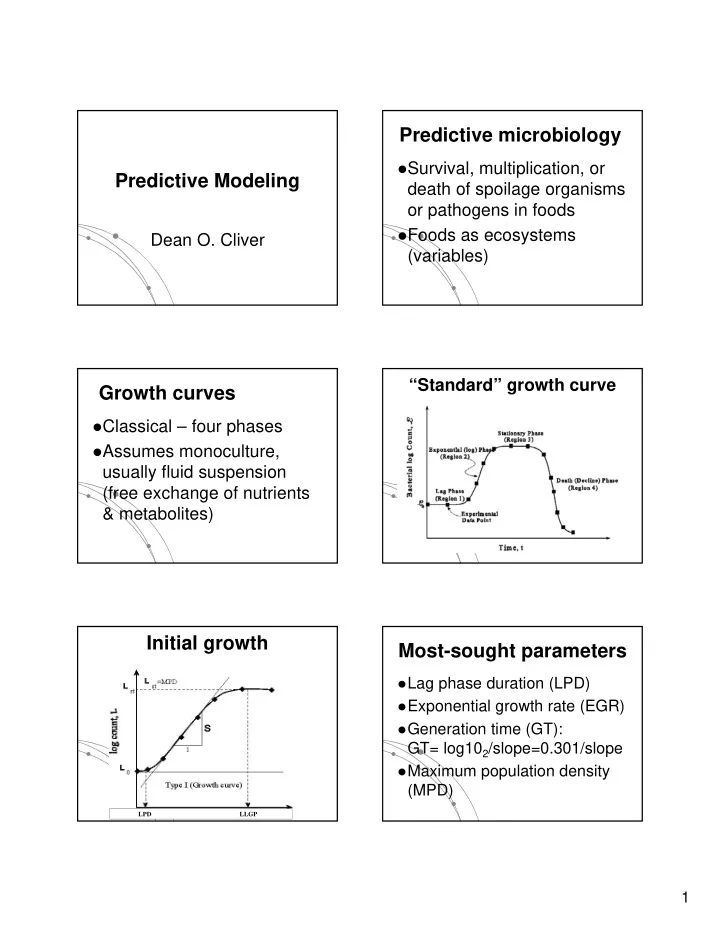

Predictive microbiology � Survival, multiplication, or Predictive Modeling death of spoilage organisms or pathogens in foods � Foods as ecosystems Dean O. Cliver (variables) “Standard” growth curve Growth curves � Classical – four phases � Assumes monoculture, usually fluid suspension (free exchange of nutrients & metabolites) Initial growth Most-sought parameters � Lag phase duration (LPD) � Exponential growth rate (EGR) � Generation time (GT): GT= log10 2 /slope=0.301/slope � Maximum population density (MPD) LPD LLGP 1

Modeling Process Modified Gompertz equation 1. Planning 2. Collection and analysis of data 3. Mathematical description of where A, B, D, and M are data (model development) empirical constants, and t is time 4. Validation and maintenance of model Generic growth curve Most-sought parameters Survival – death NaCl vs E. coli 2

NaCl vs S. aureus USDA (ARS) Pathogen Modeling Program (PMP) http://www.arserrc.gov/mfs/pathogen.htm Applications of Applications of Microbiological Modeling Microbiological Modeling � Hygienic efficiency of meat � Validity of regulations, check processing operations, rationale for mandatory codes cooling, transport, meat of practice carton thawing � Microbial fermentation, � Shelf-life studies for meat, finding optimum conditions for poultry and dairy products growth of desirable microbes (e.g., starter cultures) Applications of HACCP – Pred. Microbiol. Microbiological Modeling 1. Identify 1. Identify the � Conditions for enrichment potential microorganism(s) of target microorganisms in hazards and of concern. assess their cultures severity at � Process optimization and different stages control of processing or operations. � Product formulation � Education 3

HACCP – Pred. Microbiol. HACCP – Pred. Microbiol. 2. Identify the 2. Develop an 3. Specification of 3. Compare Critical Control understanding control criteria information with Points (CCP) of the ecology and methods to preset control where control of the ensure that a specifications measures need microorganism control has (i.e., to be to better identify been achieved accept/reject implemented. the source and (when criteria). the likelihood of necessary). contamination. HACCP – Pred. Microbiol. 4. Establish and 4. Incorporate the available implement Some examples information into monitoring monitoring procedures, systems that and response indicate measures to microbial non- proliferation. compliance situations. 4

Recommend

More recommend