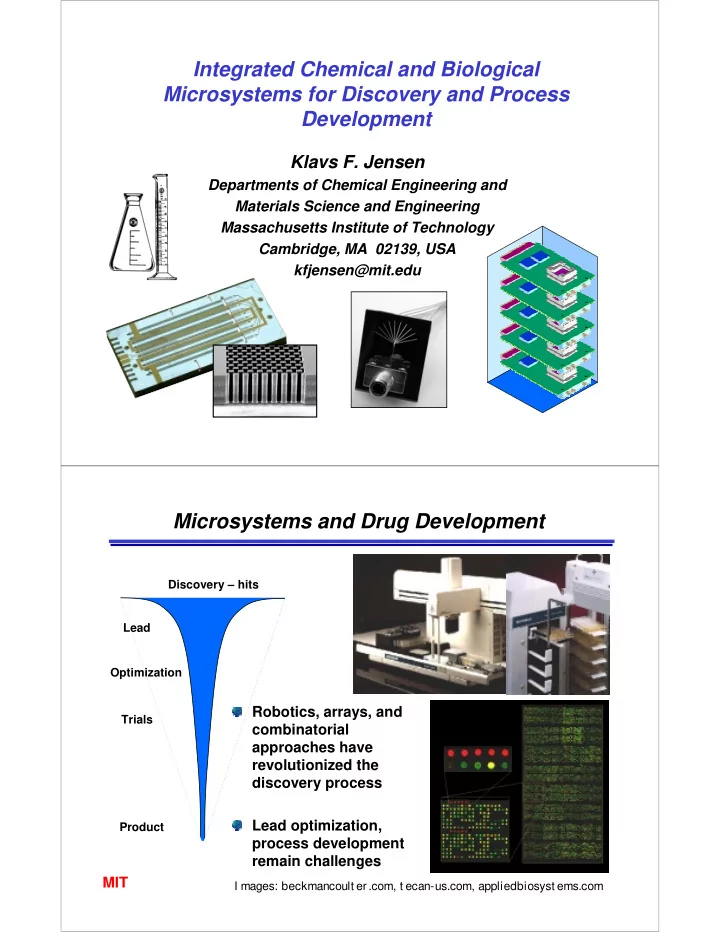

Integrated Chemical and Biological Microsystems for Discovery and Process Development Klavs F. Jensen Departments of Chemical Engineering and Materials Science and Engineering Massachusetts Institute of Technology Cambridge, MA 02139, USA kfjensen@mit.edu Microsystems and Drug Development Discovery – hits Lead Optimization Robotics, arrays, and Trials combinatorial approaches have revolutionized the discovery process Lead optimization, Product process development remain challenges MIT I mages: beckmancoult er.com, t ecan-us.com, appliedbiosyst ems.com

Biochemical and Chemical Microsystems Microfabrication has revolutionized ENIAC electronic and optical information technology Microfluidic systems are emerging for analysis (microTotal Analysis Systems) Instrumented microchemical systems could revolutionize chemical research and production by • speeding up time to production with reduced need for upfront capital investment • obtaining chemical information (e.g., kinetics) and optimize chemical processes more efficiently • providing timely, efficient synthesis platforms • providing safe and environmentally friendly research and production tools Reacto r MIT micro Total Analysis Systems (mTAS) Laboratory equipment and facilities have changed Workflow - individual, separate operations - has not evolved as rapidly ~2000 µ µ TAS integrate fluid manipulations, µ µ reactions, separations, and analysis Ultimately information management must also be included SEPARATE DETECT GEL LOADING THERMAL REACTION ~1930 DROP METERING Glass SAMPLE Silicon LOADING PC Board Wire Bonds MIT www.caliper.com Air Lines Burns et al. Science , 282, 484 (1998)

µ µ µ µ Total Analysis Systems - Biological Applications Applications J.D. Harrison • DNA identification (Univ. Alberta) • Assays • Synthesis Advantages: • www.gyrosmicro.com small volumes of expensive reagents, www.nanogen.com • parallel operation, • integration of flow, reactions, separation, and detection • integration with information management Andreas Manz, Imperial College MIT www.micronics.com Why Micro Systems? Reduced length scales 0.238 • Improved heat and mass transfer 0.198 Absorbance 0.158 • Increased surface to volume ratio 0.118 • Smaller reagent volume 0.078 0.038 -0.002 490 530 570 610 Wavelength (nm) Microfabrication • Controlled contacting of reagents • Integration of sensors and actuators • Ease of replication Chemical research and development • Safe handling of reactive, hazardous chemistry • Small amounts of expensive materials • Ease of performing experiments on new chemistry • New methods for high throughput screening • Scalable manufacturing by “numbering up” • Chem/bio information and faster development MIT

Fabrication Methods Si - MEMS LIGA (lithography + electroplating) Lamination of patterned glass,ceramic, polymer, and metal layers Rapid Prototyping (soft lithography) Micromachining (CNC, µ µ EDM, …) µ µ Si advantages: • Si and coatings compatible with chemicals • wide range of tools for micromachining • ease of integration of actuation and sensing Combination of new techniques and materials will be needed to realize advanced designs PDMS G.M. Whitesides Harvard MIT 50 µm Microreactor for Liquid Phase Chemistry Integrated Heat Exchangers and Temperature Sensors Heat Exchanger Thin-Film Temperature Sensor 300 µ m air gap cooling fluid reaction mixture U = 1500 W/m 2 °C Experiment Simulation Low Re flows - mixing by diffusion Accurate computational Optical fiber fluid dynamics predictions visible ~ 20 ms mixing time spectroscopy MIT

Microreactors Integrated with IR Spectroscopy Provide Rapid Optimization and Reaction Parameters epoxy Silicon connectors MIR crystal PDMS channels 0.5 cm 0.6 1791 2.43 s 0.5 1738 4.86 s 5 x 10 -3 Absorbance 48.6 s 0.4 Absorbance 81.0 s Acetic acid, 243 s 0.3 0.2 5 mm 0.1 0 1820 1795 1770 1745 1720 Wavelength (wavenumbers) Ethyl acetate Ethanol O O → + H 2 O + HCl 1000 1200 1400 1600 1800 MIT Cl OH Wavenumbers (cm -1 ) Microreactors for Photochemistry Potential advantages: • Continuous flow • Enhancement of mass and heat transfer • Large surface area-to-volume ratio • No deposition on window UV Lamp Conversion Immediately Following Irradiation 50% 40% conversion 30% 20% 10% 0% 0 2 4 6 8 10 12 flowrate ( µ l/min) H Subsequent O O O H O h ν (366 nm) + dark reactions + O H Model reaction: benzopinacol formation MIT

Multiphase Microreactors G L Microreactor K L a = 2-15 s -1 Mass transfer improved 100X G L Traditional multiphase packed-bed reactors: K L a = 0.001 - 0.08 s -1 100 µ µ m µ µ 36-38 µ m Dominated by mass transfer Particle size MIT Multiphase Microreactors - Hydrogenation G [ H ] Cyclohexene Hydrogenation SAT = 2 Rate 10 -4 1 1 + L η K a k (mol/s/g catalyst) L i 10 -5 Reaction Rate Microreactor Results 10 -6 10 -7 Typical 10 -8 K L a values G L 0.001 0.01 0.1 1 10 100 -1 ) K L a (s Traditional multiphase packed- bed reactors: Microreactor K L a = 2-15 s -1 K L a = 0.001 - 0.08 s -1 Mass transfer improved 100X MIT

Handling Reactive and Toxic Chemistry � COCl 2 ( ∆ ∆ H = -109 kJ/mol ∆ ∆ Phosgene synthesis CO + Cl 2 � � � Shipping and storage restrictions � � Distributed production � � 1 Conversion 0.8 On demand 0.6 synthesis of 0.4 phosgene 0.2 0 50 100 150 200 250 300 Temperature (°C) R NH 2 + COCl 2 R NH 2 + COCl 2 R NH 2 + COCl 2 R NH 2 + COCl 2 R R R R NHCOCl NHCOCl NHCOCl NHCOCl -HCl -HCl -HCl -HCl -HCl R N C O R N C O R N C O R N C O R NHCONH R R NHCONH R R NHCONH R Point-of-use synthesis of isocyanate - 10 multichannel reactors: ~ 2 g/min. MIT Microreaction Technology for Direct Fluorination Current routes to fluorinated aromatics NH 2 F + N N Multi-step process NaNO 2 /HCl ∆ − BF 4 + N 2 + BF 3 Low yields HBF 4 Not suitable for all aromatics R Obstacles for direct fluorination scale-up Room temperature F Hazardous HF and F 2 H operation gives similar Heat management + F 2 + HF (l) (g) results as experiments at (l) (l) - low temperature R very low temperature R - diluted reactants Microreactor for direct fluorination Pyrex glass Microreactors expand operating regimes – Interchannel wall allowing reactive chemistry to be performed safely Nickel under optimal conditions Silicon MIT Ni coating makes device compatible with F 2 and HF

Demonstration of Scale-Up and Integration Gas Phase Catalyst Gas Phase Catalyst x 2 Test System Test System 0.65 m 0.65 m Jim Ryley et al. DuPont 0.55 m 0.55 m David Quiram MIT Replace walk-in chemical fume hood space with desktop system System integration raise significant challenges MIT µ Fluidic Integration with Soft Lithography µ µ µ fluid out air pressure fluid in Peristaltic Pump 3D Microfluidic Networks Quake et al . Whitesides et al . Anal. Chem. Science, 288 , 113 (1999) 72 , 3158 (2000) PMDS based systems are flexible, but not compatible with most organic solvents Microfluidic Arrays Applications are primarily for Whitesides et al . Anal. Chem. 73 5207 (2000) biological systems MIT

µ µ Fluidic Systems for Biological Applications µ µ Patterning Cells in Laminar Flow Whitesides et al . Acc. Chem. Res . 33 , 841 (2000) Microfabricated Fluorescence- Activated Cell Sorter Quake et al. Nature Biotech . 17 , 110 (1999) Soft lithography methods provide opportunities for realizing microsystems with unique properties for biological applications MIT Example – Isolation of Mitochondria Would like to explore role of specific organelles in cell signaling Conventional approaches • potential artifacts with mechanical or chemical cell lysis • large samples and time consuming • study of average of large population (~10 6 ) Microsystems • novel cell lysis and organelle separation approaches • small cell populations (~10 3 ) • probe a subpopulation • integrate functions MIT

Lysing by Electroporation (HT-29 cells) Electroplated gold structure µ µ Fluidic electroporation device µ µ SU-8 wall 50 µ m 200 µ m Bond pad Gold thin film electrode Channel on glass substrate nucleus nucleus Intact cell Dissolving membrane Bare nucleus MIT IsoElectric Focusing of Mitochondria Flow beginning of channel pH gradient middle of channel end of channel MIT

Separation of Mitochondria from Cells Whole cells This experiment used full content of cell lysate and whole cells. Other fractions are not labeled, therefore not visible. Mitochondria and cells were in a homogeneous mixture at the start of the channel. Separation of mitochondria from whole cells in lysate 100 µ m achieved. Mitochondria fraction MIT Enhanced contrast Integrated Device Concept Waste Buffer inlet Micro Facs Sample inlet / Sample Image selection outlet Stimulus Further Buffer analysis inlet Sample inlet / Lysing unit Rough separation unit Fine separation unit outlet Integrated microfluidic devices could enable study of organelle and subcelluar response to stimuli MIT

Recommend

More recommend