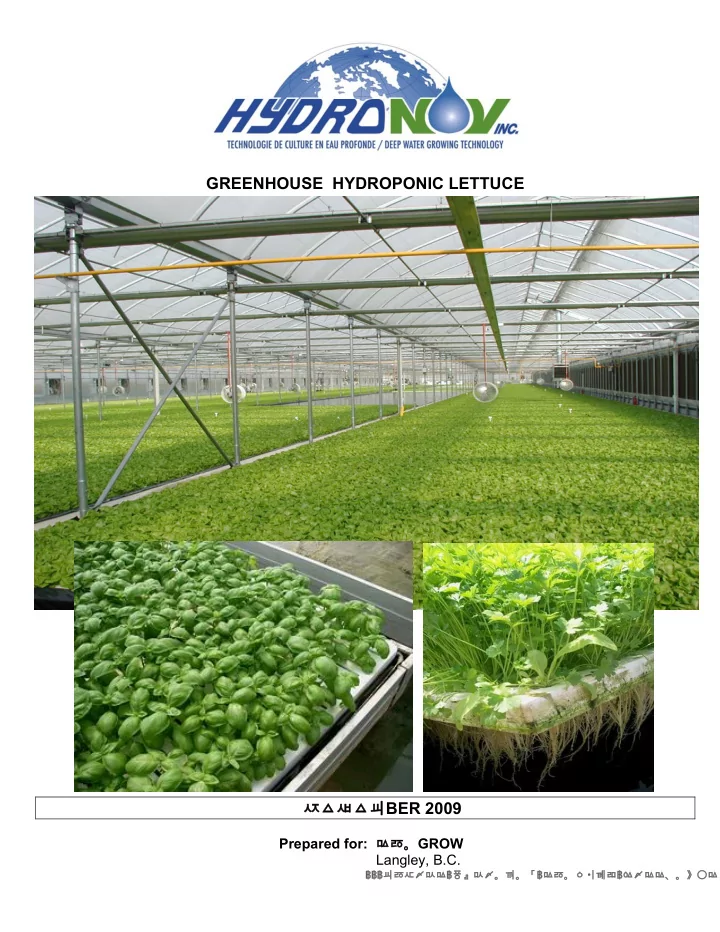

GREENHOUSE HYDROPONIC LETTUCE ����� BER 2009 Prepared for: ��� GROW Langley, B.C. ������������������������������������

HydroNov Inc . an international leader in greenhouse production since 1987, has developed and adapted several agricultural production technologies, leading to harvest far superior to traditional growing method, both in quality and quantities. HydroNov's distinctive approach is to get involved on a long term basis into technical and production supervision, bringing 20 years of hands-on experience available to each new project. HydroNov has been active and successful during the last 15 years, in exporting and implementing its technology over 30 hectares in Canada, China, Mexico, USA, Japan. Projects are currently under development in Dubai, Malaysia, Ivory Coast, Mongolia and China More information , pictures & videos at: www.hydronov.com MIRABEL, CANADA, J7N 2H4 2

1 > Introduction of the growing technology � All this expansion has been done based on the development of a revolutionary growing technique, the F loating R afts T echnology ( FRT ), for vegetables and flowers. ■ Floating Rafts Technology is certainly the most “water-conscious” system among existing hydroponic growing systems. One of its key features is the use of a large volume of water allowing enormous buffer for fertilisation and oxygen control as well as economic plants transportation by floatation. This large buffer brings a level of security and easiness that no other growing system can match. ■ With FRT absolutely no water is lost through soil or growing media, no direct evaporation to the sun, no dumping of growing solution, no dripping gutters; just plant’s needs, making it the most economical system in terms of water needs. ■ FRT leads also to a much higher productivity, bringing up the possibility to grow up to 17 crops/year of lettuce for example, at average head weight of 200 grams ■ FRT provides an integrated internal transportation system, simply using growing water as a conveyor system. A biological support base is quickly established in the growing pools, giving the plant this extra strength. No herbicides or fungicides are ever needed. Harvest Transportation System Conveyors transports the harvested lettuce into the service building where these are packed and kept in the cold storage room until sold. 3

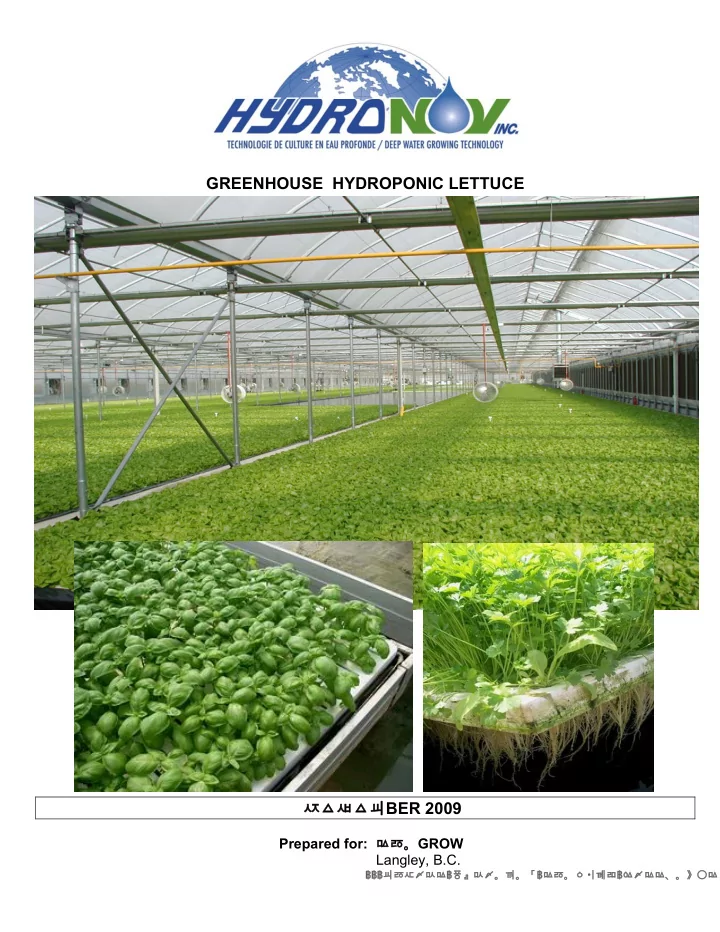

On all locations, market has been answering with enthusiasm to the arrival of a new upscale commodity, grown under a protected environment, fresh, clean, and with a constant supply. Butterhead has been adopted as a main standard for most of the greenhouse production for one simple reason: European breeders have been offering since the middle of the past century Butterhead varieties selected for their ability to grow well indoor. It was then and still is the standard lettuce for Western Europe, although recently the offer is much wider, just like in North America. No other types of lettuce seeds adapted for indoor production were offered until recently. Constant research is now bringing up the possibility to also produce a wider base of lettuce types including Romaine COS, Curly Lolo Biondo and Lolo Rosso, Oak Leaf green and red, as well as Leaf green and Red . Besides lettuce, other leafy crops can also be grown successfully, including aromatic herbs, medicinal herbs, American spinach, Chinese spinach, watercress, ….. Among other production choices: � Cooler night locations would be suitable for the production of red lettuces, due to a natural mix of quality light and cool nigh weather. The market has great expectations for a reliable source of quality greenhouse red lettuce. Red Butterhead, Lolo’s, Oak Leaf and Red Leaf types are showing great market possibilities 4

� The COS Romaine type has been a very fast growing market segment among the field grown lettuce. Beside the big size field types, greenhouse production is coming up with smaller one, bringing more quality and taste compare to its field grown counterpart � Mix Grown is an example of a product that can be easily grown in a greenhouse and marketed as a specialty item 5 �

6

A recent evolution of the FRT system is bringing up the possibility to produce all those direct seeded high density crop � , either herbs like basil, greens like Arugula or baby version of vegetables like spinach and lettuce 7

> HIGH DENSITY FLOATING SYSTEM FOR SEEDED CROPS > The HD board developed for this application integrates the advantages of Floating Rafts Technology with the simplicity and spacing flexibility of peat based media. > The end result is a highly mechanized system, where 5 workers can produce up to 320,000 KG of first quality baby leaf vegetables per hectare per year. > The direct production costs are limited to a small quantity of peat mix and a variable quantity of raw seeds, usually available at low cost. Direct labor cost is greatly reduced, the machines specially developed for this process having the capacity to supply several hectares of production within 1 shift per day. 8

2 > PROJECT DESCRIPTION The preliminary project presented here is based on year round daily harvest of lettuce 2.1 Localisation & Climatic conditions Available weather statistics for the potential location are indicating a climate with cool nigh � temperature year round, an important factor for quality leafy vegetables. We are as well expecting humidity to be on the high side, and winter light not sufficient to grow a quality crop without artificial lighting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � Detailed weather statistics will need to be provided when location is confirmed � 2.2 Choice of production systems HydroNov has developed over time 2 different yet complementary floating rafts systems: - The 1 inch block system for whole head production * Will produce more weight per surface * Do require more labour for handling of individual head * Appropriate for densities between 20 and 100 plants per M2 * Will produce regular and small size lettuces - The peat base system for high density seeded crop * Fully automated system from seeding to harvest * For densities from 500 to 2,000 seeds per M2 * Will produce baby type seeded vegetables like baby spinach, mizuna, and all baby lettuces 2.3 Project Numbers We will for now limit our project description to whole head lettuce The high density vegetables remains an option to consider . The choice between whole head and high density is a question of market. Obviously high density leaf must sell at a higher price to compensate the lower productivity. 9

PROJECT DESCRIPTION AND PRODUCTION CAPACITY / PHASE 1 Location: McBride HydroNov ecoGROW Greenhouse BC Customer: ecoGROW Crop Butterhead lettuce Dimensions (meters) Production area Block identification 1 Length 150.0 m Width 153.6 m 23 040 m 2 Covered area 19 833 m 2 Growing area Production boards 26 096 Nursery area Length 150.0 m Width 48 m 7 200 m 2 Covered area 4 958 m 2 Growing area Nursery boards 6 524 Testing area Testing Boards 0 Summary 31 315 m 2 Total Project Area 30 240 m 2 Total greenhouse area 24 791 m 2 Total growing area 5 449 m 2 Working & Transportation area 0 m 2 NetHouse circulation area 1 075 m 2 Packing & Warehouse area Capacity of Production Density 24.0 plants / m2 Annual Crop rotation 17.0 / year Total Harvest / m2 408 Marketable plants 85% Potential harvest per square meter 347 plants/m2/year for growing area 6 878 071 plant/year for sale 573 173 dozen/year 1 432 931 KILOS/year From testing Area Other greens 0 KILOS/year Expected Production Hours Expected Water Requirements (litres) 82,796 At Fill-up 7,437,360 On monthly basis 1,239,560 * IMPORTANT NOTICE PROJECTIONS & ANALYSIS ADAPTED TO LOCAL CONDITIONS BASED ON AVAILABLE DATA ALL NUMBERS MENTIONED FOR INFORMATION ONLY.

3- Project Cost Building, equipment and Services for the project are proposed at a firm price of 7,432,432 CND$. Other expenses related to land preparation, infrastructure and construction are estimated at $ 1,455,000 . McBride HydroNov ecoGROW greenhouse PRICE SUMMARY / PHASE 1 $ CDN 1- Land & services 200,000 Primary services 2-Greenhouse building 1,642,368 800,000 Installation 3-Greenhouse equipments 1,827,840 4-Services building+equipments 183,456 55,000 Internal partitions 5- Cold storage area 87,360 6- Floating raft growing system 2,032,128 7- Production equipment 833,280 100,000 Misc 8- Delivery & insurances 112,000 9-Installation & Concrete works 294,000 300,000 Concrete & Drainage 10- Follow-up/ Prod. Supplies 420,000 11-TOTAL $7,432,432 $1,455,000 $8,887,432 TERMS AND CONDITIONS *TRAVELLING EXPENSES INCLUDED * C.I.F. SITE * STATUS OF PROPOSAL : Preliminary * PAYABLE BY IRREVOCABLE LETTER OF CREDIT * ALL IN CDN $

Recommend

More recommend