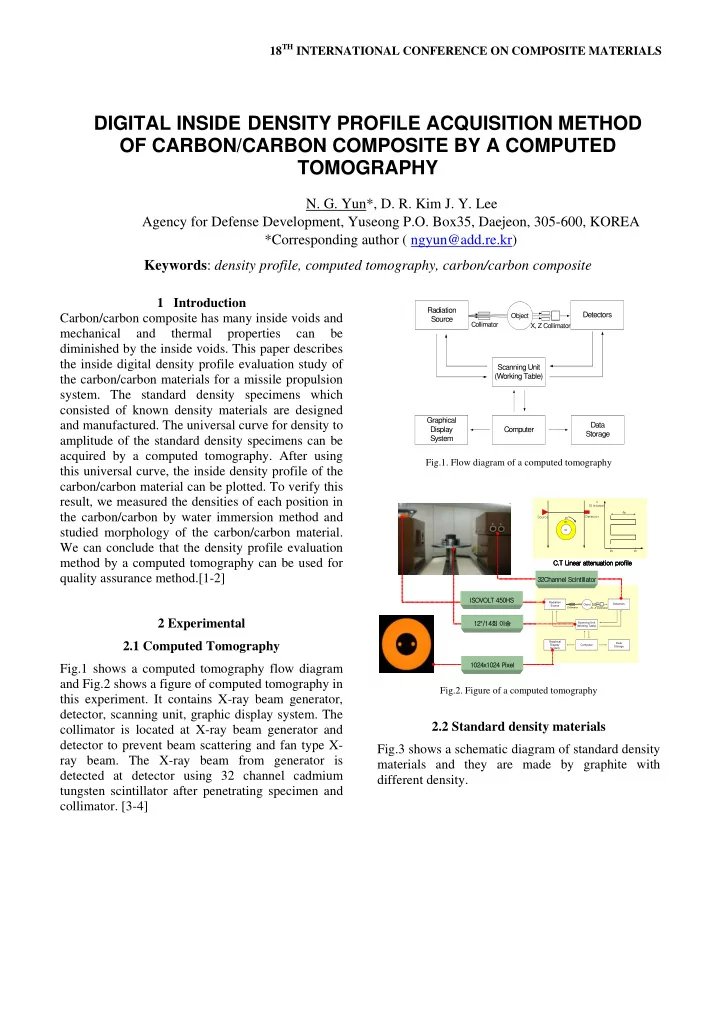

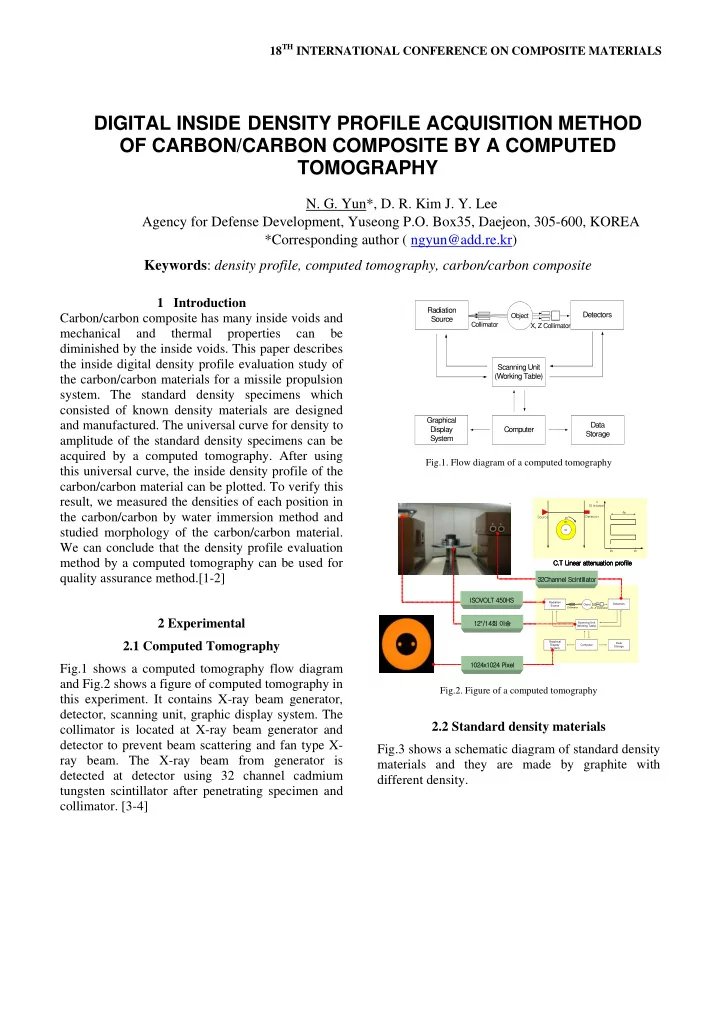

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS DIGITAL INSIDE DENSITY PROFILE ACQUISITION METHOD OF CARBON/CARBON COMPOSITE BY A COMPUTED TOMOGRAPHY N. G. Yun*, D. R. Kim J. Y. Lee Agency for Defense Development, Yuseong P.O. Box35, Daejeon, 305-600, KOREA *Corresponding author ( ngyun@add.re.kr) Keywords : density profile, computed tomography, carbon/carbon composite 1 Introduction Radiation Detectors Carbon/carbon composite has many inside voids and Object Source Collimator X, Z Collimator mechanical and thermal properties can be diminished by the inside voids. This paper describes the inside digital density profile evaluation study of Scanning Unit (Working Table) the carbon/carbon materials for a missile propulsion system. The standard density specimens which consisted of known density materials are designed Graphical and manufactured. The universal curve for density to Data Display Computer Storage System amplitude of the standard density specimens can be acquired by a computed tomography. After using Fig.1. Flow diagram of a computed tomography this universal curve, the inside density profile of the carbon/carbon material can be plotted. To verify this result, we measured the densities of each position in x x x (Distance) (Distance) (Distance) Δμ Δμ Δμ the carbon/carbon by water immersion method and μ b μ b μ b Detector Detector Detector Source Source Source μ n μ n μ n studied morphology of the carbon/carbon material. μ b μ b μ b We can conclude that the density profile evaluation μ b μ b μ b μ n μ n μ n method by a computed tomography can be used for C.T Linear attenuation profile C.T Linear attenuation profile C.T Linear attenuation profile quality assurance method.[1-2] 32Channel Scintillator 32Channel Scintillator ISOVOLT 450HS ISOVOLT 450HS Radiation Radiation Object Object Detectors Detectors Source Source Collimator Collimator X, Z Collimator X, Z Collimator 2 Experimental 12°/14회 이송 12°/14회 이송 Scanning Unit Scanning Unit (Working Table) (Working Table) 2.1 Computed Tomography Graphical Graphical Data Data Display Display Computer Computer Storage Storage System System 1024x1024 Pixel 1024x1024 Pixel Fig.1 shows a computed tomography flow diagram and Fig.2 shows a figure of computed tomography in Fig.2. Figure of a computed tomography this experiment. It contains X-ray beam generator, detector, scanning unit, graphic display system. The 2.2 Standard density materials collimator is located at X-ray beam generator and detector to prevent beam scattering and fan type X- Fig.3 shows a schematic diagram of standard density ray beam. The X-ray beam from generator is materials and they are made by graphite with detected at detector using 32 channel cadmium different density. tungsten scintillator after penetrating specimen and collimator. [3-4]

180° φ 73.0 +0.0 -0.2 2 mm B 밀도 A: 1.7489 g/cm 3 12.5 B: 1.7595 g/cm 3 270° 90° C A C: 1.8188 g/cm 3 D: 1.8566 g/cm 3 1 mm D +0.1 φ 15.2 -0.0 φ 15.0 +0.0 0° -0.2 2 mm 73.2 20.00 140 140 A B C D Voxel Size(0.2x0.2x1.5 mm) Fig.4. Schematic diagram of voxel image 15 15 15 Voxel Size(0.2x0.2x1.5 mm) Fig.3. Schematic diagram of standard density material Voxel Size(1.0x1.0x1.5 mm) 0.024 Standard Material A Voxel Size(2.0x2.0x1.5 mm) Standard Material B 0.020 Standard Material C 3 Results Standard Material D 0.016 3.1 Correction of linear beam hardening f(x) 0.012 Computed tomography image is affected by linear 0.008 beam hardening and Fig.4 shows a corrected image by polychromatic correction method. 0.004 0.000 Modification imgage 20000 17500 18000 18500 19000 19500 20000 20500 21000 CT number 15000 Fig.5. Standard deviation according to voxel size CT number Origainal image 10000 Table 1 CT number of the standard density materials 5000 CT number Standard density Mean materials 0 Min Max RMSD Percent 18,795 18,247.59 A 17,669 184.73 1.012 0 100 200 300 400 19,048 18,370.69 Distance(mm) B 17,809 185.60 1.010 19,679 19,045.14 C 18,331 193.47 1.016 Fig.4. Correction of beam hardening 20,224 19,548.53 D 18,901 216.90 1.110 3.2 Density distributions by voxel size Table 2 Confidence level for each voxel size The voxel size from computed tomography is shown Voxel size Min Max Mean RMSD Confidence in Fig. 5. If a void is existed in a voxel by the 20224.00 19548.53 216.91 computed tomography image the calculated density 18901.00 42.00% 0.2×0.2×1.5 mm will be decreased and the density distribution will be 19794.80 19548.53 101.35 19269.30 1.0×1.0×1.5 mm 76.37% broad. The density of standard density materials is 19666.84 19548.53 49.18 19448.91 related to CT number and table 1 shows normal 2.0×2.0×1.5 mm 98.53% distribution of standard density materials A, B, C, D and table 2 shows confidence level for each voxel size.

3.3 CT number profiles of carbon/carbon composite Fig. 6 and Fig. 7 shows CT number profile of carbon/carbon composite from computed tomography. 1.90 1.88 o A 90 o A 270 1.86 o B 90 o B 270 o C 270 Fig.8. Procedure of digital inside density profile acquisition program 3 ) o C 90 Density(g/cm 1.84 1.82 1.80 1.78 1.76 0 20 40 60 80 100 120 140 160 180 200 Distance(mm) Fig.6. CT number of X axis 1.90 1.88 o A 0 o A 180 o B 1.86 180 o B 0 o C 0 o C 180 Density(g/cm 3 ) 1.84 Fig.9. Result of digital inside density profile acquisition program 1.82 1.80 1.78 3.5 Morphology of carbon/carbon 1.76 Fig. 10 shows carbon/carbon composite inside 0 20 40 60 80 100 120 140 160 180 200 morphology. Distance(mm) Fig.7. CT number of Y axis 3.4 Density distributions of carbon/carbon The results of digital inside density profile acquisition program shows Fig.8-9. Fig.10. Morphology of carbon/carbon composite

4 Conclusions The standard density materials are designed and the CT number of 2.0 x 2.0 x 1.5mm voxel size by the computed tomography is converted to the density value in the carbon/carbon material. The converted density value is compared to real density by water immersion method. Two density values are very similar at same position in the carbon/carbon material. References [1] D. H. Phillips and J. J. Lannutti, "Measurement physical density with X-ray computed tomography", NDT & E International, vol. 30, 1997, pp.339-350 [2] R. T. Lopes, H. S. Rocha, E. F. O. de Jesus, R. C. Barroso, L. F. de Oliveira, M. J. Anjos, D. Braz and S. Moreira, "X-ray transmission microtomography using synchrotron radiation", Nuclear Instruments and Methods in physics Research, 2003, pp.604-607 [3] “Radiography and Radiation testing”, ASNT Non destructive Handbook 2Ed, Vol 3, Section 5, 1985, pp.839-878 [4] “Standard Guide for Computed Tomography (CT) Imaging”, ASTM E1441-00, pp.1-32, (1992)

Recommend

More recommend