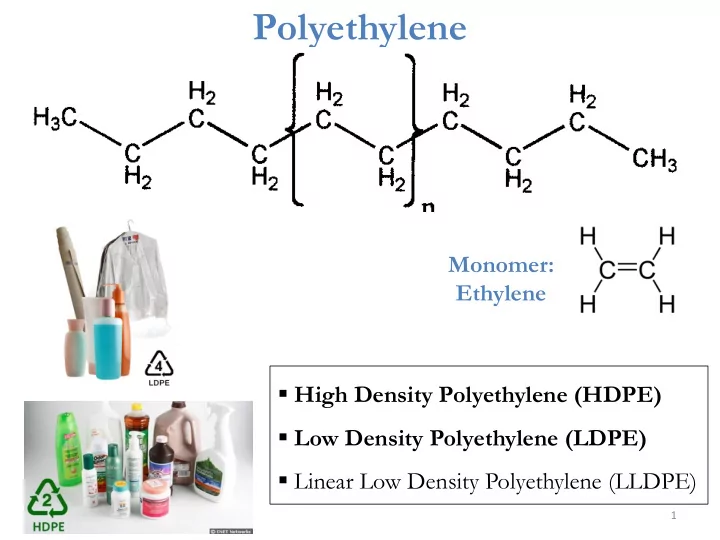

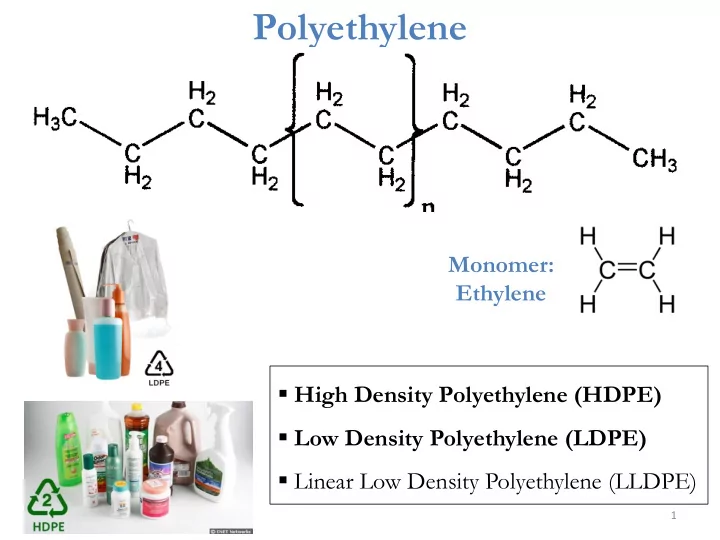

Polyethylene Monomer: Ethylene High Density Polyethylene (HDPE) Low Density Polyethylene (LDPE) Linear Low Density Polyethylene (LLDPE) 1

Low Density Polyethylene (LDPE) High Density Polyethylene (HDPE ) High degree of short and long chain Low degrees of branching (essentially branching linear) Density - 0.910 – 0.940 g/cm 3 Density > 0.940 g/cm 3 Lower tensile strength and increased High tensile strength Various catalysts (ZN, Metallocene) ductility Free radical polymerization Milk jugs, detergent bottles, garbage Plastic bags and film wrap containers and water pipes Long chain branching Short chain branching Hyperbranched (HDPE) (LLDPE) (LDPE) 2

Timeline of Polyethylene 1898 Synthesized by accident while heating diazomethane (Called Poly- “ methylene ” due to repeating – CH 2 group) 1930-35 First polymerization of ethylene at Imperial Chemical Industries. Advent of the free radical process to produce LDPE 3

Free Radical Polymerization 1. INITIATION (You need Initiators) AIBN Benzoyl Peroxide 4

Free Radical Polymerization 2. PROPAGATION High pressure is needed during the propagation step in order to bring the ethylene monomer closer to the free radicals 5

Free Radical Polymerization 3. TERMINATION (Many ways) a. COUPLING 6

Free Radical Polymerization 3. TERMINATION (Many ways) b. DISPROPORTIONATION 7

Free Radical Polymerization 3. TERMINATION (Many ways) c. CHAIN TRANSFER (Hydrogen Abstraction) 8

Free Radical Polymerization SIDE REACTIONS (Causes Branching) 9

Disadvantages 1. Uncontrolled Process • Structure, Molecular weight 2. Requires high pressure 3. Reactions are highly exothermic 4. Inefficient process (20% ethylene polymerized) 10

Timeline of Polyethylene 1898 Synthesized by accident while heating diazomethane (Called Poly- “ methylene ” due to repeating – CH 2 group) 1930-35 First polymerization of ethylene at Imperial Chemical Industries. Advent of the free radical process to produce LDPE 1950’s Ziegler-Natta Catalyst (Inorganic Catalyst for HDPE) 11

Zieglar-Natta Catalyst 12

Zieglar-Natta Catalyst Mechanism 13

Timeline of Polyethylene 1898 Synthesized by accident while heating diazomethane (Called Poly- “ methylene ” due to repeating – CH 2 group) 1930-35 First polymerization of ethylene at Imperial Chemical Industries. Advent of the free radical process to produce LDPE 1950’s Ziegler-Natta Catalyst (Inorganic Catalyst for HDPE) 1970’s Metallocene Catalyst (Organic-Inorganic Hybrid Catalyst for HDPE) 14

Metallocene Catalyst Zirconium Sandwich The Bread is Cyclopentadiene The Filling is Zr bonded to Chlorine 15

Timeline of Polyethylene 1898 Synthesized by accident while heating diazomethane (Called Poly- “ methylene ” due to repeating – CH 2 group) 1930-35 First polymerization of ethylene at Imperial Chemical Industries. Advent of the free radical process to produce LDPE 1950’s Ziegler-Natta Catalyst (Inorganic Catalyst for HDPE) 1970’s Metallocene Catalyst (Organic-Inorganic Hybrid Catalyst for HDPE) What is next ? Organic Routes (biological enzymatic reactions) 16

Zieglar-Natta Catalyst Mechanism 17

Recommend

More recommend