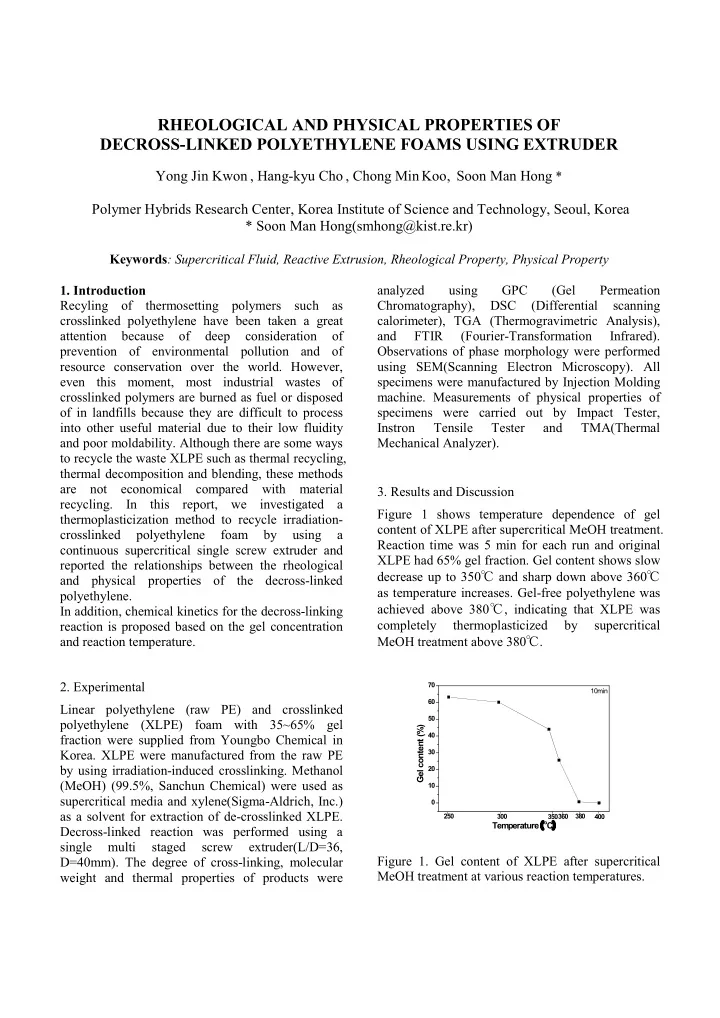

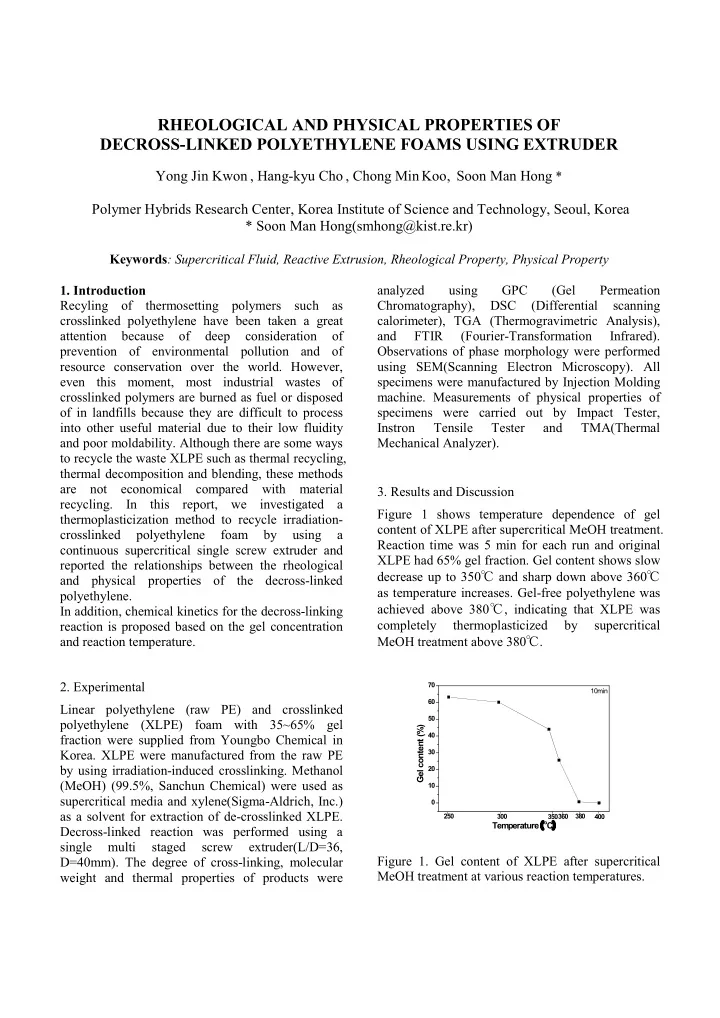

RHEOLOGICAL AND PHYSICAL PROPERTIES OF DECROSS-LINKED POLYETHYLENE FOAMS USING EXTRUDER Yong Jin Kwon , Hang-kyu Cho , Chong Min Koo, Soon Man Hong * Polymer Hybrids Research Center, Korea Institute of Science and Technology, Seoul, Korea * Soon Man Hong(smhong@kist.re.kr) Keywords : Supercritical Fluid, Reactive Extrusion, Rheological Property, Physical Property 1. Introduction analyzed using GPC (Gel Permeation Recyling of thermosetting polymers such as Chromatography), DSC (Differential scanning crosslinked polyethylene have been taken a great calorimeter), TGA (Thermogravimetric Analysis), attention because of deep consideration of and FTIR (Fourier-Transformation Infrared). prevention of environmental pollution and of Observations of phase morphology were performed resource conservation over the world. However, using SEM(Scanning Electron Microscopy). All even this moment, most industrial wastes of specimens were manufactured by Injection Molding crosslinked polymers are burned as fuel or disposed machine. Measurements of physical properties of of in landfills because they are difficult to process specimens were carried out by Impact Tester, into other useful material due to their low fluidity Instron Tensile Tester and TMA(Thermal and poor moldability. Although there are some ways Mechanical Analyzer). to recycle the waste XLPE such as thermal recycling, thermal decomposition and blending, these methods are not economical compared with material 3. Results and Discussion recycling. In this report, we investigated a Figure 1 shows temperature dependence of gel thermoplasticization method to recycle irradiation- content of XLPE after supercritical MeOH treatment. crosslinked polyethylene foam by using a Reaction time was 5 min for each run and original continuous supercritical single screw extruder and XLPE had 65% gel fraction. Gel content shows slow reported the relationships between the rheological decrease up to 350 ℃ and sharp down above 360 ℃ and physical properties of the decross-linked as temperature increases. Gel-free polyethylene was polyethylene. achieved above 380 ℃ , indicating that XLPE was In addition, chemical kinetics for the decross-linking completely thermoplasticized by supercritical reaction is proposed based on the gel concentration MeOH treatment above 380 ℃ . and reaction temperature. 2. Experimental 70 10min 60 Linear polyethylene (raw PE) and crosslinked 50 polyethylene (XLPE) foam with 35~65% gel Gel content (%) 40 fraction were supplied from Youngbo Chemical in Korea. XLPE were manufactured from the raw PE 30 by using irradiation-induced crosslinking. Methanol 20 (MeOH) (99.5%, Sanchun Chemical) were used as 10 supercritical media and xylene(Sigma-Aldrich, Inc.) 0 as a solvent for extraction of de-crosslinked XLPE. 250 300 350 360 380 400 o C ) Temperature ( Decross-linked reaction was performed using a single multi staged screw extruder(L/D=36, Figure 1. Gel content of XLPE after supercritical D=40mm). The degree of cross-linking, molecular MeOH treatment at various reaction temperatures. weight and thermal properties of products were

Table 1 shows molecular weight of the thermoplasticized XLPE by supercritical MeOH at 2.5 various temperatures. Molecular weight is Raw LDPE measuring by using the extracted from the treated 2.0 XLPE by hot xylene. Molecular weight of the Absorbance 360 o C 1.5 extracted decreases with temperature. Especially, the extracted from the treated XLPE containing 26% gel, o C 380 1.0 has lower molecular weight and broader molecular weight distribution than raw PE. This indicates that o C 400 0.5 chain decomposition takes place at random site, not at the selective crosslinking junctions. XLPE 0.0 4000 3500 3000 2500 2000 1500 1000 -1 ) Wavenumber (cm Table 1. Characterizations of raw PE and XLPEs Figure 2. FT-IR spectra of raw PE, XLPE and the treated XLPEs at various temperatures. after supercritical MeOH treatment at various temperature Figure 3 shows crystallization curves and melting curves of LDPE and XLPEs before and after supercritical treatment. All curves were measured in Gel the second run with the heating and cooling rates of Molecular Weight Temperature 10 o C/min. All DSC data were listed in Table 1. In content Figure 4a, the treated XLPEs had higher ( o C) (%) Mn Mw PDI crystallization temperature than XLPE. Partially or fully decrosslinked XLPE may have higher degree of freedom in chain mobility than XLPE because of 360 25.6 22,000 277,000 12.6 lower gel fraction. It appeared to help the treated XLPE start to crystallize higher temperature. Hence, 380 0.7 15,000 201,000 13.0 crystallization temperature of the crosslinked increased with the reaction temperature. In addition, the decrosslinked had higher crystallization 400 0 11,000 74,000 6.9 temperature than LDPE as well. It could be understood by the fact that the commercial XLPE was including a variety of additives such as Raw LDPE 0 40,000 343,000 8.5 pigments and foaming agents, and the additives could play as an effective nucleation agent. In Figure 4b, every sample had one melting endothermic peak, indicating a unimodal lamella. LDPE had melting Figure 2 shows FT-IR spectra of raw PE and XLPEs temperature of 100.7 o C. The decrosslinked had before and after supercritical treatment. All samples higher T m than LDPE and XLPE as well. show the same FT-IR curve as raw PE. Each sample Crystallinity X c.DSC was calculated from heat of has characteristic two peaks of polyethylene: 2800- fusion, D H m , using the following equation 1: 3000cm -1 peak of sp 3 C-H stretching and 1450cm -1 peak of CH 2 bending. Absence of new peaks such as X c.DSC = D H m / D H m.PE sp 2 C-H (3000-3300cm -1 ), sp C-H (>3300cm -1 ), C=C (1) (1600-1650cm -1 ), C=O (1600-1800 cm -1 ) peaks in , where D H m.PE =277 J/g was the theoretical heat of FT-IR of treated XLPE indicates absence of undesirable side reaction such as oxidation and fusion of perfect crystalline high density polyethylene. 11 The decrosslinked had the almost disproportionation in the supercritical methanol. same crystallinity about X c.DSC =0.5 as LDPE.

using Bragg’s law in equation 3 and orthorhombic plane distance relationship in equation 4. (a) XLPE l = d (3) 350 hkl q 2 sin Heat Flow hkl 360 2 2 2 1 h k l 370 = + + (4) 380 2 2 2 2 a b c d hkl 400 All WAXS results were also summarized in Table 1. LDPE Endo LDPE had orthorhombic lattice dimensions of a=7.39 Å , b=4.97 Å and crystallinity X c.WAXS = 0.55. 60 80 100 120 The decrosslinked XLPEs had the almost same unit o C) Temperature ( cell dimensions and X c.WAXS as the LDPE. In addition, the crystallinity from WAXS, X c.WAXS was pretty consistent with that from DSC, X c.DSC . (b) XLPE (110) 350 Heat Flow 360 Arbitrary Intensity (200) 370 380 400 XLPE LDPE 350 Endo 360 370 40 60 80 100 120 380 400 o C) Temperature ( LDPE 10 15 20 25 2 q Figure 3. DSC thermographs of LDPE and the decrosslinked XLPEs (A) at cooling scan and (b) heating scan. Figure 4. WAXS patterns of LDPE and the decrosslinked XLPEs at various temperatures. Figure 4 shows WAXS patterns of LDPE and Figure 5 shows storage moduli (E’) of LDPE and the XLPEs before and after supercritical treatment. Each decrosslinked XLPEs at various temperatures. sample had characteristic three scattering peaks: Storage modulus of XLPE was not measured (110) and (200) plane reflection peaks from because of its poor moldability. Storage modulus of orthorhombic unit cell of polyethylene and a broad the decrosslinked gradually decreased with the amorphous halo from amorphous portion. temperature until a steep drop appeared at the glass Crystallinity X c.WAXS was calculated from WAXS transition. LDPE (solid line) was compared with the using the following equation 2: decrosslinked. Storage modulus of the decrosslinked slowly decreased with reaction temperature. The X c.WAXS = (I(110)+I(200))/I total (2) decrosslinked had a little higher storage modulus than LDPE up to 360 o C, but lower storage modulus , where I(110), I(200) were intensity of (110) and 370 o C. than LDPE above Nonetheless, the (200) reflections and I total was the total observed decrosslinked XLPE had comparable storage intensity. The unit cell dimensions were calculated modulus with LDPE up to 380 o C. It could be 3

Recommend

More recommend