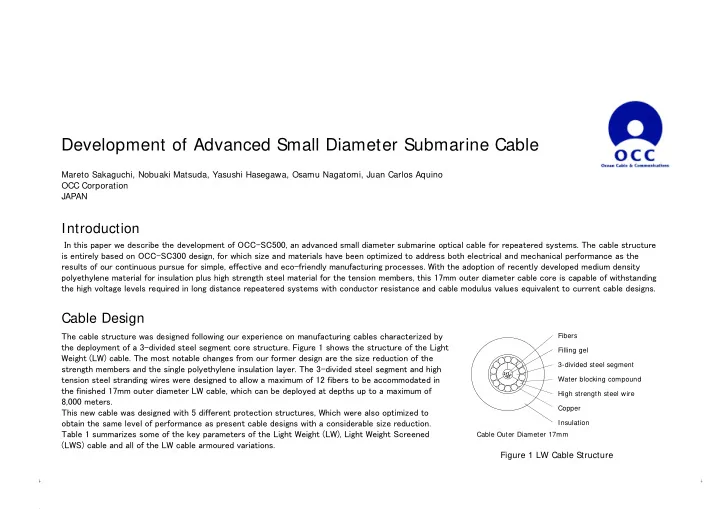

Development of Advanced Small Diameter Submarine Cable Mareto Sakaguchi, Nobuaki Matsuda, Yasushi Hasegawa, Osamu Nagatomi, Juan Carlos Aquino OCC Corporation JAPAN Introduction In this paper we describe the development of OCC-SC500, an advanced small diameter submarine optical cable for repeatered systems. The cable structure is entirely based on OCC-SC300 design, for which size and materials have been optimized to address both electrical and mechanical performance as the results of our continuous pursue for simple, effective and eco-friendly manufacturing processes. With the adoption of recently developed medium density polyethylene material for insulation plus high strength steel material for the tension members, this 17mm outer diameter cable core is capable of withstanding the high voltage levels required in long distance repeatered systems with conductor resistance and cable modulus values equivalent to current cable designs. Cable Design The cable structure was designed following our experience on manufacturing cables characterized by Fibers the deployment of a 3-divided steel segment core structure. Figure 1 shows the structure of the Light Filling gel Weight (LW) cable. The most notable changes from our former design are the size reduction of the 3-divided steel segment strength members and the single polyethylene insulation layer. The 3-divided steel segment and high tension steel stranding wires were designed to allow a maximum of 12 fibers to be accommodated in Water blocking compound the finished 17mm outer diameter LW cable, which can be deployed at depths up to a maximum of High strength steel wire 8,000 meters. Copper This new cable was designed with 5 different protection structures, Which were also optimized to obtain the same level of performance as present cable designs with a considerable size reduction. Insulation Table 1 summarizes some of the key parameters of the Light Weight (LW), Light Weight Screened Cable Outer Diameter 17mm (LWS) cable and all of the LW cable armoured variations. Figure 1 LW Cable Structure

Table 1 SC500 Cable Parameters Cable Type Item Unit LW LWS SA SAH DA DAH Outer Diameter mm 17 23.5 28 31 41 44 Armouring 3.0 4.6 mm -- -- 3.0 4.6 Wire Diameter 4.6 4.6 Weight in air kN/km 6.0 8.6 18.6 25.9 46.8 56.9 SAH SA Weight in water kN/km 3.8 4.3 13.4 19.6 36.0 44.5 > 77 > 77 > 250 > 320 > 580 > 690 CBL kN NTTS kN 60 60 200 230 350 400 NOTS kN 48 48 130 175 260 300 NPTS kN 22 22 80 100 140 160 Ω /km DC Resistance (@3degC) 1.0 Ω⋅ km > 2 × 10 11 Insulation Resistance DAH DA Maximum Power Feeding kV 15 Voltage Figure 2 Armoured Cable Structure Maximum Deployment Depth m 8,000 6,000 2,000 1,500 500 200 SA: Single Armoured SAH: Single Armoured Heavy DA: Double Armoured DAH: Double Armoured Heavy Joint Box and Coupling Current cable joint box and couplings were re-designed to accommodate the new cable dimensions while maintaining complete compatibility with current cable designs. Figure 3 shows a schematic drawing of the joint Box and couplings for armoured cables. Major components’ structures and dimensions are kept unchanged for optimum compatibility between all our different cable designs. Figure 3 Coupling and Joint Box Evaluation Test structure for armoured cables Performance of each cable type was tested and confirmed following the LMF1 LMF2 TENSION DAH Cable Tensile Performance ITU-T Recommendation G.976 and internal standards. Results obtained 0.015 500 0.50 confirmed that this compact Cable design reaches the same level of 450 0.45 mechanical performance and reliability in conformance to the latest 0.010 400 0.40 system requirements. Attenuation change [ dB] Cable Elongation [% ] 0.35 350 Cable Tension [kN] 0.005 Joint box and coupling evaluation included the build and testing of 0.30 300 several samples covering every type of cable combination. 0.25 0.000 250 Figure 4 shows the tensile test result for DAH cable during the tensile test 0.20 200 with twist restrained. -0.005 0.15 150 Figure 5 shows the DAH to DAH cable joint box tensile test results. 0.10 100 Attenuation change for two different types of large core non- zero -0.010 0.05 50 dispersion shifted fibers are depicted. We can note that attenuation 0.00 -0.015 0 variation reaches its largest value holding the cable and joint box samples 0 100 200 300 400 500 0 30 60 90 120 150 180 Cable Tension [kN] under the peak tensile load. After unloading the cable, these attenuation Time [min] changes are relaxed to negligible levels. Figure 4 DAH Cable Tensile Test Result Figure 5 DAH-DAH JB Tensile Test Result

Sea Trial Shallow water sea trial off the coast of Tsushima Island was conducted on single armoured cable C-1 JB-1 REP-1 C-3 C-2 JB-2 S.R.-1 at the end of December 2009 to confirm the cable handling with standard cable ship equipment SC500 SC300 SC500 SC500 LWS LW LW LW Cable Ship and monitor its optical attenuation changes during installation, burial to 1.5m, and recovery JB(R) CPL Rep CPL JB(R) 2000 operations. Negligible attenuation change was observed throughout the marine operations, Dummy 11.1km 15km 26.7km 12.2km confirming the cable’s stable mechanical and optical performance. 50km T otal System Length: 4000 Additional deep sea trial conducted on May 2010, on the sea area near the Ogasawara Trench LWS T otal System Length: 65km confirmed the performance of the LW and LWS cables as well as combination Joint Box and Actual deployment depth 8600m 8400m 8600m 6000 repeater coupling. Figure 6 describes the deep sea trial cable SLD and actual deployment depths. All elements were deployed to water depths exceeding 8,000m. Figure 7 shows the optical LW LW 8000 attenuation change on two different fiber loops as well as the cable tension during the deep sea cable deployment, hold and recovery operations. Although a very small attenuation change remained just after cable recovery, this variation decreased to negligible levels after a period of time. Figure 8 shows the repeater as it reaches the cable ship during recovery. Figure 9 shows Figure 6 Deep Sea Trial Cable SLD the LW cable while is coiled after recovery from 8,600m water depths. Optical Attenuation Change during Deep Sea Trial deployment and recovery DMF1 DMF2 TENSION Attenuation Decreases 0.020 60.0 REP-1 JB-1 JB-1 REP-1 JB-2 JB-2 SR-1 C-3 C-2 C-3 SR-1 C-2 C-1 C-1 0.015 50.0 Attenuation Change [dB/ km] 0.010 40.0 Cable Tension[kN] 0.005 30.0 0.000 20.0 -0.005 10.0 -0.010 0.0 -0.015 -10.0 HOLD RECOVERY LAY -0.020 -20.0 0:16 2:07 3:58 5:49 7:40 9:31 11:22 13:13 15:04 16:55 18:46 20:37 22:28 0:19 2:10 4:01 5:52 7:43 9:34 11:25 13:16 15:07 16:58 18:49 20:40 22:31 0:22 2:13 4:04 5:55 7:46 9:37 11:28 13:19 15:10 17:01 18:52 20:43 22:34 0:25 2:16 4:07 5:58 7:49 9:40 11:31 13:22 15:13 17:04 18:55 20:46 22:37 0:28 2:19 4:10 6:01 7:52 Attenuation Increases Figure 8 Repeater while recovered from 8,400m 5/6 5/2 5/4 5/5 5/3 Time Figure 7 Attenuation change and cable tension during deep sea operations Conclusion New reduced size cable development was successfully finished. The new OCC-SC500 series with its compact design was confirmed to fulfill all the requirements of current systems. Performance during sea trial confirmed not only its easy handling properties but also demonstrated its ability to withstand deployment and recovery operations at water depths exceeding 8,000m without optical or mechanical characteristics variations. Figure 9 LW cable coiling after recovery from 8,600m

Recommend

More recommend