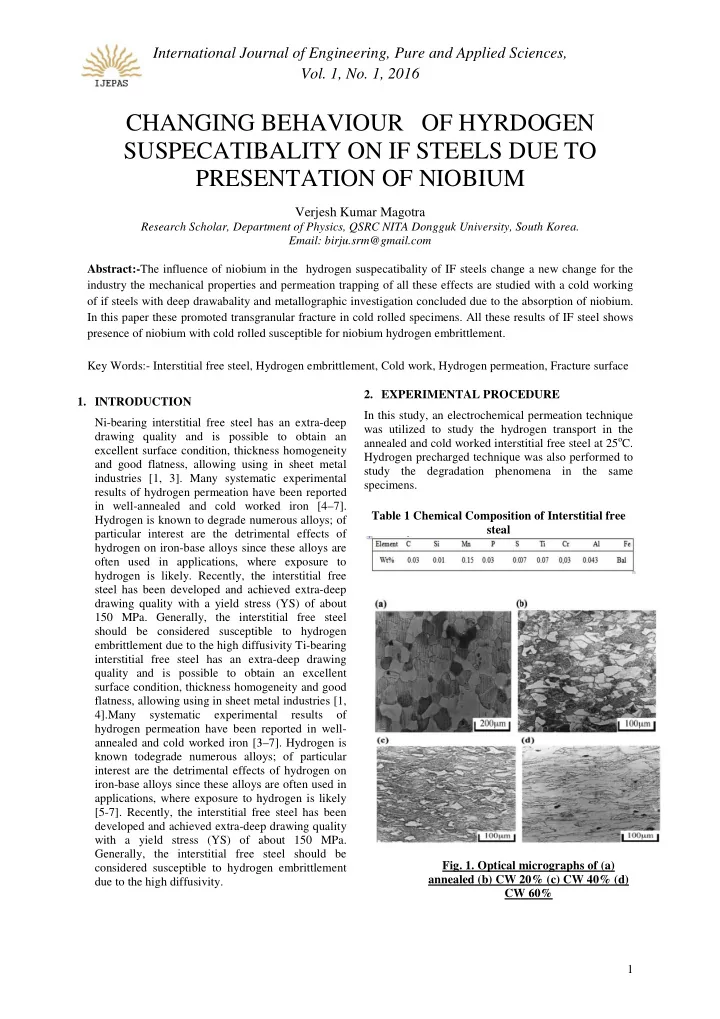

International Jour ournal of Engineering, Pure and Applied Sc Sciences, Vol. 1, No. 1, 2016 CHANGING B G BEHAVIOUR OF HYRD DOGEN SUSPECATIB IBALITY ON IF STEELS D DUE TO PRESE SENTATION OF NIOBIUM M Verjesh Kumar Magotra South Korea. Research Scholar, Depar artment of Physics, QSRC NITA Dongguk University, So Email: birju.srm@gmail.com Abstract:- The influence of niobium um in the hydrogen suspecatibality of IF steels change ge a new change for the industry the mechanical properties a s and permeation trapping of all these effects are studie died with a cold working of if steels with deep drawabality an and metallographic investigation concluded due to the a e absorption of niobium. In this paper these promoted transgr sgranular fracture in cold rolled specimens. All these re results of IF steel shows led susceptible for niobium hydrogen embrittlement. presence of niobium with cold rolled Key Words:- Interstitial free steel, H , Hydrogen embrittlement, Cold work, Hydrogen permea eation, Fracture surface 2. EXPERIMENTAL PROCE CEDURE 1. INTRODUCTION In this study, an electrochemical cal permeation technique Ni-bearing interstitial free steel h l has an extra-deep was utilized to study the hydr drogen transport in the drawing quality and is possibl ible to obtain an rstitial free steel at 25 o C. annealed and cold worked interst excellent surface condition, thickn kness homogeneity Hydrogen precharged technique ue was also performed to and good flatness, allowing using ing in sheet metal study the degradation pheno nomena in the same industries [1, 3]. Many systema matic experimental specimens. results of hydrogen permeation ha have been reported in well-annealed and cold wor orked iron [4–7]. Table 1 Chemical Compositio tion of Interstitial free Hydrogen is known to degrade num numerous alloys; of steal particular interest are the detrim rimental effects of hydrogen on iron-base alloys since nce these alloys are often used in applications, whe here exposure to hydrogen is likely. Recently, the the interstitial free steel has been developed and ach chieved extra-deep drawing quality with a yield stres tress (YS) of about 150 MPa. Generally, the inters terstitial free steel should be considered susceptib ble to hydrogen embrittlement due to the high diffu ffusivity Ti-bearing interstitial free steel has an ext extra-deep drawing quality and is possible to obta btain an excellent surface condition, thickness homog ogeneity and good flatness, allowing using in sheet m metal industries [1, 4].Many systematic experimen ental results of hydrogen permeation have been r n reported in well- annealed and cold worked iron [3 [3–7]. Hydrogen is known todegrade numerous alloy lloys; of particular interest are the detrimental effects cts of hydrogen on iron-base alloys since these alloys ys are often used in applications, where exposure to h hydrogen is likely [5-7]. Recently, the interstitial fre free steel has been developed and achieved extra-deep eep drawing quality with a yield stress (YS) of a about 150 MPa. Generally, the interstitial free e steel should be Fig. 1. Optical m l micrographs of (a) considered susceptible to hydroge ogen embrittlement annealed (b) CW 2 20% (c) CW 40% (d) due to the high diffusivity. CW W 60% 1

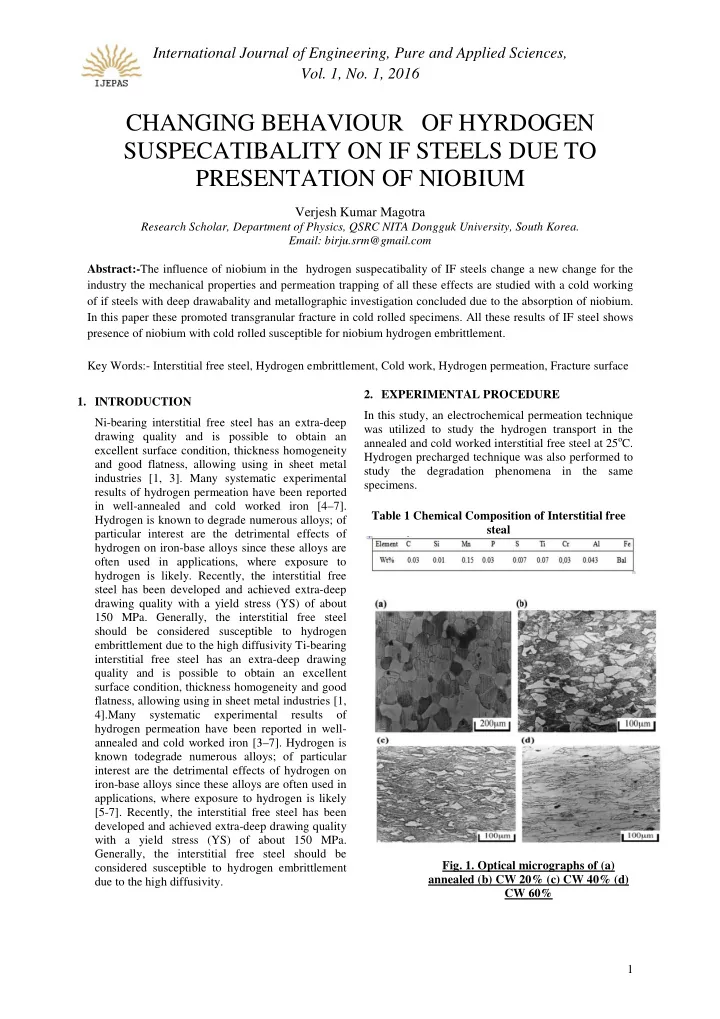

International Journal of Engineering, Pure and Applied Sciences, Vol. 1, No. 1, 2016 Table-B preparation of these specimens involves cold rolled to Permeation rate, diffusivity for the interstitial free different percent - age reduct ion and optical steel with a constant charging current density (10 micrograp has are shown in Fig. 1. Then these mA/cm2 at25Jc specimens were ground with Carbimet- Sic grining paper down to 800 grit. Prior to the insertion in the IF steel J ∞ L (mol(H)/ms D eff ( m2/s) 2/s) test cell, each speci men was nickel plated (200 nm) on the anodic side to eliminate surface defects. Annealed 1.65 x 10 �� 7.81x 10 ��� Table-4 CW 20% 2.59x 10 �� 1.77 x 10 ��� CW 40% 1.88x 10 �� 1.18x 10 ��� CW 60% 4.72x 10 �� 1.18x 10 ��� CW 80% 3.66x 10 �� 3.55x 10 ��� The instrumentation and procedure were similar to those described elsewhere [8-10]. The cathodic site or hydrogen entry cell was galvano statically polarized at a constant charging current in 0. 1 N Na OH. The anodic side or hydroge n exit cell was potentiostated at 250 mV (SCE) in 0.1 N Noah. The potent iostatic curren t, i p , gives a direct measure of the hydrogen flow rate. The cell assembly was immersed at 25 F 0.5 j C. Both sides were deoxygen ated.The materials chosen for this study were an interstitial free steel and were provided by China Steel Corporation. Chemical compositions of the interstitial free steel are listed in Table 1. Specimens were cut from steel plate then heated at 850 j C for 1 hand furnace cooled. The Fig.2 Fracture surface of CW 80% specimen: (a) preparation of these specimens involves cold rolled to different percent - age reduct ion and optical micrograp uncharged and (b) 5-days cathodic charged. has are shown in Fig. 1. Then these specimens were ground with Carbimet- Sic grining paper down to 800 The instrumentation and procedure were similar to grit. Prior to the insertion in the test cell, each speci those described elsewhere [8-10]. The cathodic site or men was nickel plated (200 nm) on the anodic side to hydrogen entry cell was galvano statically polarized at eliminate surface defects. a constant charging current in 0. 1 N Na OH. The anodic side or hydroge n exit cell was potentiostated at 250 mV (SCE) in 0.1 N Noah. The potent iostatic curren t, i p , gives a direct measure of the hydrogen flow rate. The cell assembly was immersed at 25 F 0.5 j C. Both sides were deoxygen ated.The materials chosen for this study were an interstitial free steel and were provided by China Steel Corporation. Chemical compositions of the interstitial free steel are listed in Table 1. Specimens were cut from steel plate then heated at 850 j C for 1 hand furnace cooled. The 2

Recommend

More recommend