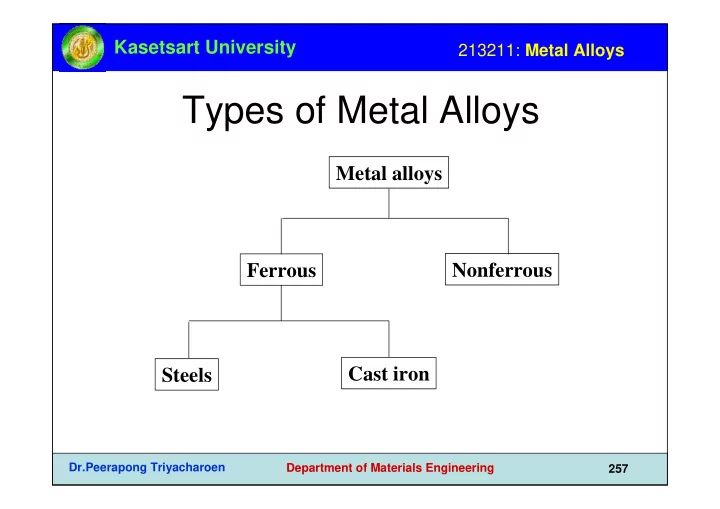

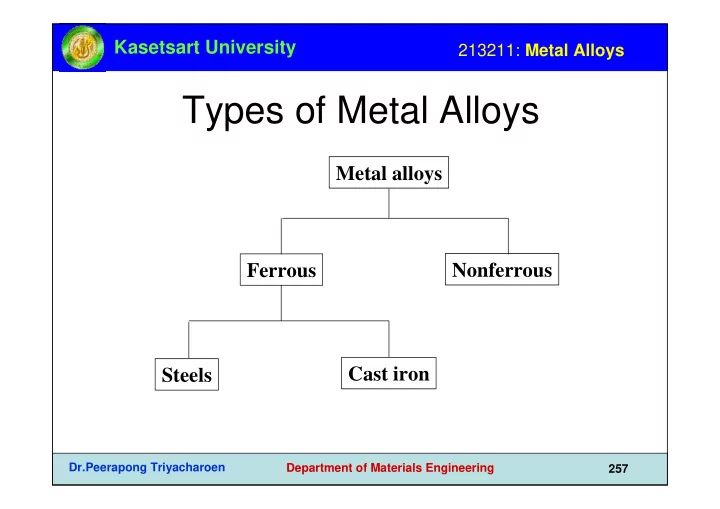

Kasetsart University 213211: Metal Alloys Types of Metal Alloys Metal alloys Nonferrous Ferrous Cast iron Steels Dr.Peerapong Triyacharoen Department of Materials Engineering 257

Kasetsart University 213211: Metal Alloys Steels High Alloy Low Alloy low carbon med carbon high carbon <0.25wt%C 0.25-0.6wt%C 0.6-1.4wt%C heat austentitic Name plain HSLA plain treatable plain tool stainless Cr,V Cr, Ni Cr, V, Additions none Ni, Mo none none Cr, Ni, Mo Mo Mo, W Example 1010 4310 1040 4340 1095 4190 304 Hardenability 0 + + ++ ++ +++ 0 - 0 + ++ + ++ 0 TS + + 0 - - -- ++ EL high T pistons Uses auto bridges crank wear drills applic. gears struc. towers shafts applic. saws turbines wear sheet press. bolts dies furnaces applic. vessels hammers V. corros. blades resistant increasing strength, cost, decreasing ductility Dr.Peerapong Triyacharoen Department of Materials Engineering 258

Kasetsart University 213211: Metal Alloys Dr.Peerapong Triyacharoen Department of Materials Engineering 259

Kasetsart University 213211: Metal Alloys Cast Irons Gray Iron Nodular Iron White Iron Malleable Iron Dr.Peerapong Triyacharoen Department of Materials Engineering 260

Kasetsart University 213211: Metal Alloys Nonferrous Alloys • Cu Alloys • Al Alloys -lower ρ : 2.7g/cm3 Brass: Zn is subst. impurity (costume jewelry, coins, -Cu, Mg, Si, Mn, Zn additions corrosion resistant) -solid sol. or precip. Bronze: Sn, Al, Si, Ni are strengthened (struct. subst. impurity aircraft parts (bushings, landing & packaging) NonFerrous gear) • Mg Alloys Cu-Be: -very low ρ : 1.7g/cm3 Alloys precip. hardened -ignites easily for strength -aircraft, missles • Ti Alloys • Refractory metals -lower ρ : 4.5g/cm3 -high melting T vs 7.9 for steel • Noble metals -Nb, Mo, W, Ta -Ag, Au, Pt -reactive at high T -oxid./corr. resistant -space applic. Dr.Peerapong Triyacharoen Department of Materials Engineering 261

Kasetsart University 213211: Metal Alloys Refinement of Steel from Ore Coke Limestone Iron Ore BLAST FURNACE heat generation gas C+O2 → CO2 refractory vessel reduction of iron ore to metal CO2+C → 2CO layers of coke 3CO+Fe2O3 → 2Fe+3CO2 and iron ore air purification slag CaCO3 → CaO+CO2 Molten iron CaO + SiO2 +Al2O3 → slag Dr.Peerapong Triyacharoen Department of Materials Engineering 262

Kasetsart University 213211: Metal Alloys Metal Fabrication Methods (I) FORMING CASTING JOINING • Forging • Rolling (wrenches, crankshafts) (I-beams, rails) force roll die Ad often at Ao Ao Ad blank elev. T roll force • Drawing • Extrusion (rods, wire, tubing) (rods, tubing) Ao die Ad container die holder tensile force Ao ram Ad billet extrusion force die die container Dr.Peerapong Triyacharoen Department of Materials Engineering 263

Kasetsart University 213211: Metal Alloys Metal Fabrication Methods-II FORMING CASTING JOINING • Sand Casting • Die Casting (large parts, e.g., (high volume, low T alloys) auto engine blocks) Sand Sand molten metal • Continuous Casting • Investment Casting (simple slab shapes) (low volume, complex shapes molten e.g., jewelry, turbine blades) solidified plaster die formed wax around wax prototype Dr.Peerapong Triyacharoen Department of Materials Engineering 264

Kasetsart University 213211: Metal Alloys Metal Fabrication Methods-III FORMING CASTING JOINING • Powder Processing • Welding (materials w/low ductility) (when one large part is impractical) pressure filler metal (melted) base metal (melted) fused base metal heat heat affected zone area unaffected unaffected contact piece 1 piece 2 densify • Heat affected zone: densification point contact (region in which the microstructure by diffusion at at low T has been changed). higher T Dr.Peerapong Triyacharoen Department of Materials Engineering 265

Kasetsart University 213211: Metal Alloys Thermal Processing of Metals Annealing: Heat to T anneal , then cool slowly. • Spheroidize (steels): • Stress Relief : Reduce Make very soft steels for stress caused by: good machining. Heat just -plastic deformation -nonuniform cooling below T E & hold for -phase transform. 15-25h. • Full Anneal (steels): Types of Make soft steels for Annealing good forming by heating to get γ , then cool in furnace to get coarse P. • Process Anneal : Negate effect of • Normalize (steels): cold working by Deform steel with large (recovery/ grains, then normalize recrystallization) to make grains small. Dr.Peerapong Triyacharoen Department of Materials Engineering 266

Kasetsart University 213211: Metal Alloys Dr.Peerapong Triyacharoen Department of Materials Engineering 267

Recommend

More recommend