The Value of Nondestructive Testing for New Transmission & - PowerPoint PPT Presentation

The Value of Nondestructive Testing for New Transmission & Substation Foundations Presented by Rakesh Anthony Khan, P.E., CWI, FDH Infrastructure Services SEPTEMBER 5 - 7, 2018 Definition of NDT Webster defines nondestructive testing or

The Value of Nondestructive Testing for New Transmission & Substation Foundations Presented by Rakesh Anthony Khan, P.E., CWI, FDH Infrastructure Services SEPTEMBER 5 - 7, 2018

Definition of NDT Webster defines nondestructive testing or non-destructive testing (NDT) as a wide group of analysis techniques used in science and technology industry to evaluate the properties of a material, component or system without causing damage.[1] The terms nondestructive examination (NDE), nondestructive inspection (NDI), and nondestructive evaluation (NDE) are also commonly used to describe this technology.[2] Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. The six most frequently used NDT methods are eddy-current, magnetic-particle, liquid penetrant, radiographic, ultrasonic, and visual testing.[3] NDT is commonly used in forensic engineering, mechanical engineering, petroleum engineering, electrical engineering, civil engineering, systems engineering, aeronautical engineering, medicine, and art.[1] Innovations in the field of nondestructive testing have had a profound impact on medical imaging, including on echocardiography, medical ultrasonography, and digital radiography. With the advent of machine learning, computer vision and data-driven techniques, nondestructive testing has been improved in different fields. [4] applied data-driven and machine learning techniques to predict damage state based solely on visual observations in infrastructures. SEPTEMBER 5 - 7, 2018 2 of 50

Background SEPTEMBER 5 - 7, 2018 3 of 22

Testing SEPTEMBER 5 - 7, 2018 4 of 22

Nondestructive Testing Measure material properties. Structures are assets too. SEPTEMBER 5 - 7, 2018 5 of 22

Nondestructive Testing - Metals SEPTEMBER 5 - 7, 2018 6 of 22

Nondestructive Testing - Concrete SEPTEMBER 5 - 7, 2018 7 of 22

Nondestructive Testing of Foundations Variable medium. Very little access. Visual inspection can be misleading. Types of Testing Crosshole Sonic Logging (CSL) • Gamma Gamma Logging (GGL) • Thermal Integrity Profiling (TIP) • Sonic Echo/Impulse Response (SE/IR) • Technician experience is required to collect meaningful data. Engineer experience is required to interpret test results. SEPTEMBER 5 - 7, 2018 8 of 22

Crosshole Sonic Logging SEPTEMBER 5 - 7, 2018 9 of 22

Gamma Gamma Logging SEPTEMBER 5 - 7, 2018 10 of 22

Thermal Integrity Profiling SEPTEMBER 5 - 7, 2018 11 of 22

Sonic Echo Impact t Amplitude Length Time (in μ s) Dispersive Wave SEPTEMBER 5 - 7, 2018 12 of 22

Substation Construction Example Project in construction phase. Several foundations poured. Some structures already set. Potential Integrity Issues • Known geotechnical challenges • Additional concrete poured in many locations • CSL testing had unclear results SEPTEMBER 5 - 7, 2018 13 of 22

Geotechnical Challenge - Karst Geology Formed by the dissolution of rocks, such as limestone or • dolomite Sink holes, disappearing streams, springs • Highly variable subsurface conditions, soft soils, variable • water conditions, voids SEPTEMBER 5 - 7, 2018 14 of 22

Karst Prevalence SEPTEMBER 5 - 7, 2018 15 of 22

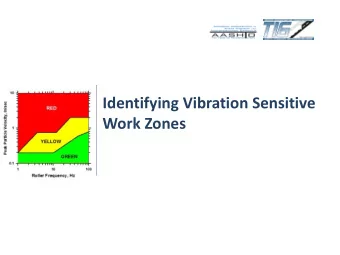

FDH Testing at this Site • Dispersive Wave (DW) testing was carried out on the foundations • Piers were segmented into 6 or 8 sections (depending on the foundation size) – 2 testing setups were performed in each section • Setup 1 – Direct • Setup 2 – Across Pier SEPTEMBER 5 - 7, 2018 16 of 22

Dispersive Wave Testing Results Site GEO, construction notes, and CSL testing results were also reviewed as part of the investigation Likelihood of integrity issues presented on a color scale based on DW analysis as well as other information available Possible Issues Soil intrusions propagating past the • rebar cage Bearing depth concerns • Voids or inclusions of soil • Coring location selected to determine magnitude of issue SEPTEMBER 5 - 7, 2018 17 of 22

Concrete Core Process • Results reviewed with plan to determine the magnitude of the indicated issues by coring at select locations • Coring locations just inside the rebar cage to quantify the extent of the integrity issue and evaluate if it would affect the foundation’s capacity • Cores performed along the inside of rebar cage • Core Results: o Major soil intrusion inside rebar cage o Bearing depth discrepancies o ‘Golf ball to baseball’ sized inclusions o Small zones where concrete was not fully mixed SEPTEMBER 5 - 7, 2018 18 of 22

Corrosion Assessment Prior to Construction 13 samples tested by three different consulting companies • Slightly to moderately aggressive • 12 of 13 tests are slightly aggressive o 1 of 13 tests is moderately aggressive o Resistivity 1100 (ohm.cm) to 15000 (ohm.cm) • pH > 7.9 • Chloride < 146 ppm • Sulfate < 169 ppm • Corrosion Evaluation 3 processes to classify the corrosion risk were utilized • 1) FHWA Undisturbed soil: No corrosion • Disturbed soil: 3 samples qualified for • 0.08 (mm/yr) for 50 years 2) CALTRANS: Non corrosive Environment • 3) Mughabghab (1989): Corrosion rate of 0.03 (mm/yr) for 50 years • Conclusion Average of 1.5 mm of corrosion after 50 years: 4% of the • rebar size Include this in Capacity Calculations and any Remediation • Methods SEPTEMBER 5 - 7, 2018 19 of 22

Capacity Determination • Capacity evaluations performed based on the soil intrusion size and corrosion risk • The voids were conservatively sized • Evaluation for compression and section loss in rebar within the tension zone • Identified the overall capacities of the foundations SEPTEMBER 5 - 7, 2018 20 of 22

Result Transmission standards group within the Utility was involved in assumption processes for analysis and performed verification calculations. Worst case foundations would live past their intended service life. No further action necessary. Exploratory cores pressure grouted. No removal of structures already placed. No major project delay. SEPTEMBER 5 - 7, 2018 21 of 22

Key Learnings Karst soil conditions present • construction difficulties. Conservative design valuable in karst • soils. Knowledge of NDT options is important. • Experience in applying NDT for • actionable results is critical. NDT techniques can confirm installation • quality, resolve issues, and save costs. SEPTEMBER 5 - 7, 2018 22 of 22

Questions? SEPTEMBER 5 - 7, 2018

Founded in 1994 by Civil Engineering PhDs • Infrastructure engineering & NDT services • company. 180+ employees Headquartered in Raleigh, NC • Licensed across the US • Patented and proprietary NDT methods • Services for Telecom, Heavy Civil, Power, • Industrial, Commercial, and Government Structural Engineering Civil Engineering Geotechnical Engineering Nondestructive Testing Structure Design Permitting Support Lab Analysis Dispersive Wave Foundation Design New Site Development Resistivity Testing Ground Penetrating Radar (GPR) Structural Evaluation Site Remediation Drilling Portfolio Infrared (IR) Thermography Modification Design Bridge Scour Analysis Geotechnical Reports Concrete Strength Rigging Plans Environmental Compliance Ultrasonic Testing Mount Analysis Temporary Access Matting Corrosion Post-Tensioned Rod Solutions Field Investigations Construction Services Research & Development Value Added Inspection Construction PhD-led group Research & Development Foundation Mapping Construction Management Structures Laboratory Failure/Forensic Investigations Structure Mapping Painting & Lead Abatement Refine existing NDT Expert Witness Testimony Mount Mapping Emergency Restoration Develop new NDT Line & Antenna Mapping Training & Investigation SEPTEMBER 5 - 7, 2018

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.