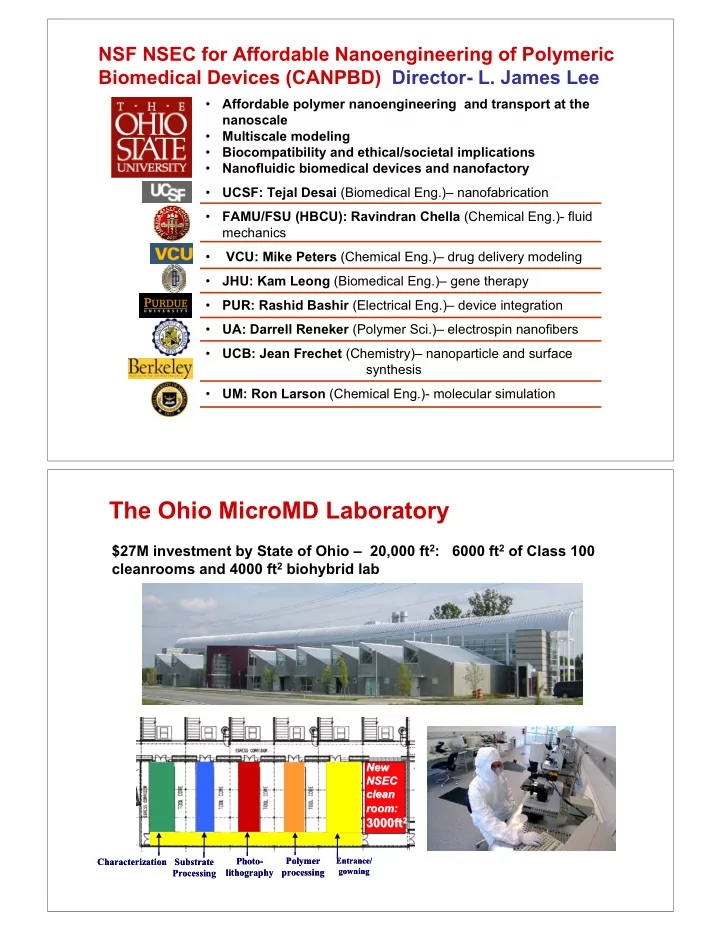

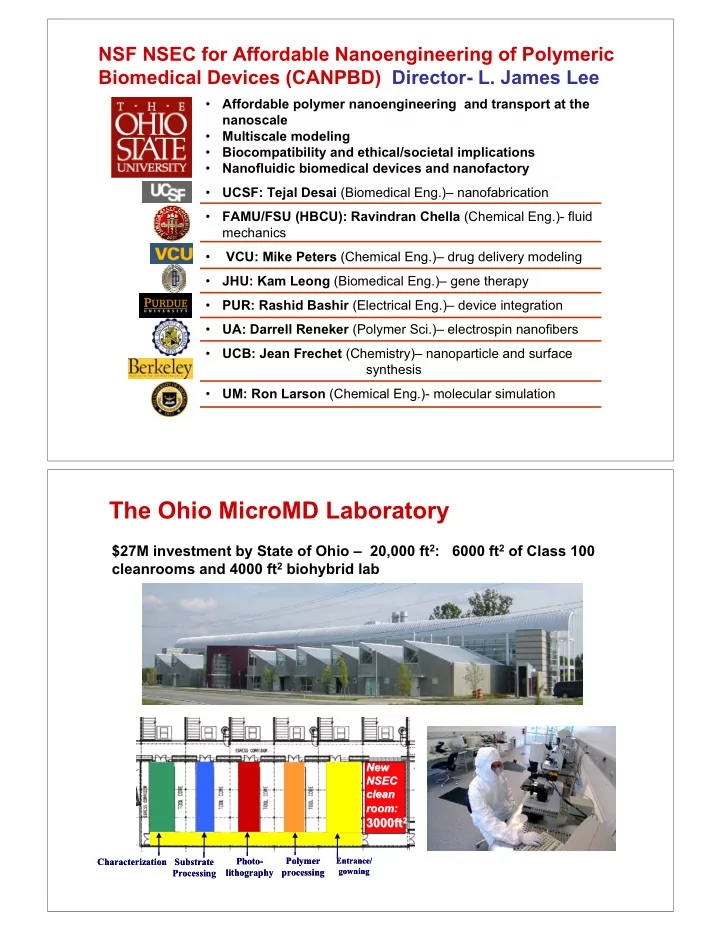

NSF NSEC for Affordable Nanoengineering of Polymeric Biomedical Devices (CANPBD) Director- L. James Lee • Affordable polymer nanoengineering and transport at the nanoscale Multiscale modeling • • Biocompatibility and ethical/societal implications • Nanofluidic biomedical devices and nanofactory UCSF: Tejal Desai (Biomedical Eng.)– nanofabrication • • FAMU/FSU (HBCU): Ravindran Chella (Chemical Eng.)- fluid mechanics • VCU: Mike Peters (Chemical Eng.)– drug delivery modeling JHU: Kam Leong (Biomedical Eng.)– gene therapy • • PUR: Rashid Bashir (Electrical Eng.)– device integration UA: Darrell Reneker (Polymer Sci.)– electrospin nanofibers • UCB: Jean Frechet (Chemistry)– nanoparticle and surface • synthesis UM: Ron Larson (Chemical Eng.)- molecular simulation • The Ohio MicroMD Laboratory $27M investment by State of Ohio – 20,000 ft 2 : 6000 ft 2 of Class 100 cleanrooms and 4000 ft 2 biohybrid lab New New NSEC NSEC clean clean room: room: 3000ft 2 3000ft 2 Polymer Polymer Characterization Characterization Substrate Substrate Photo- Photo- Entrance/ Entrance/ gowning gowning lithography lithography processing processing Processing Processing

Micro/Nanomachining Lab 1. Micro-milling machine 2. Nano-grinding machine 3a. Femtosecond Pulse Laser/Proximal Probe on a SEM 3b. Assisted High Precision Magnetic Suspension Stage 1 4. Three-axial Sputtering Machine 2 3a 3b 4 Micro/Nanoprocessing Lab 1. EVG Aligner and Nano-imprintingSystem 2. EVG Hot-Embossing Machine 1 3. SCF Molding/Bonding System 4. Micro-injection Molding Machine 2 5. Dip Pen Lithography System 6. Plasma RIE 7. PECVD 3 4 8. Electroplating 9. Photolithography System 8 7 9 6 5

Nanoscale Characterization Lab 1. Instron Micro-Tester 2. Bio-AFM 1 3 2 3. High Pressure-Ellipsometry (with hot stage) 4. High Pressure-Surface Nano-Rheometer 5. BIC Dynamic Light Scattering Goniometer 5 6. BIC Zeta/Stream Potential Measurement System 4 7. Environmental SEM 8. Cryo TEM 9. Static/Dynamic Contact Angle Measurement System 10. Dual Beam Optical Tweezer 6 11. Size Exclusion Chromatograph 11 9 7 10 Micro/Nanofluidics Lab 1. Invert Fluorescence Microscope 2. Syringe Pumps 3. Spin-Disk Confocal Micro-PIV 1 2 4. High Speed CCD System 5. Multi-Electrode EOF/EP System 6. Centrifuge Micro/Nanofluidic Device 7. Automated Micro-Pipette System 3 4 5 7 6

� � � � � � � � � � � � � � � � Nanofactory Nanofluidic Nanofluidic Protein Drug/Gene Delivery Separation Testbeds Super/Subcritical Manufacturing Self/Dynamic Manipulation Micro/Nano Assembly Fluidics Nanofiber Synthesis Fluids Nano Nano Core Technology Platform Thrust Areas ( Nanoengineering, Multiscale Modeling, Biocompatibility ) Building Blocks ( Functional Polymers, Biomolecules, Nanoparticles ) Electro Spinning of Nanofibers Electro Spinning of Nanofibers Wound Dressing Wound Dressing Contact: D. Reneker (U. Akron) NANOFIBERS H 2 O S K I N - Acid - Nitrite - Super absorbent NO NO NO NO NO NO NO NO NO NO NO NO - Nanofiber Nitric Oxide release for 6 to 12 hours Promotes Wound Healing Time Elapsed – 8 days 3 month old skin lesions cured in one or two weeks!

3D Tissue Culture and An Adipose Tissue a b A piece of adipose tissue taken 3D scaffold seeded with embryonic from the body and prepared for stem cells that have been induced SEM to become fat cells (adipocytes) REFLECTION MODE OF OPTICAL MICROSCOPY ELECTROSPINNING/SOLUTION CASTING HYBRID PROCESSING PLATFORM Air + solvent vapor Air Air + solvent vapor Embedded PEO nanofibers in PAA matrix Air Electrospinning Casting Contact: M. Cakmak ( Cakmak@uakron.edu), Ph#330-972-6928

Effect of CO 2 on Surface T and Chain Diffusion Effect of CO 2 on Surface T g g and Chain Diffusion Neutron Reflectivity AFM/Gold Particles 35 o C h PS d PS substrate w/o CO 2 w CO 2 20 nm �� interfacial width 20 110 T g, bulk = 100.2 o C Interfacial Width , nm 100 15 90.6 o C good fusion 12.2 nm 90 10 Tg , oC 80 70 5 60 R g = 11.3 nm 10.3 nm 50 0 0 2000 4000 6000 8000 40 0 5 10 15 200 205 210 Time , s Depth , nm Y. Yang, and L.J. Lee, , The Ohio State University CO 2 Bonding at the Nanoscale Nanoscale (PS) (PS) CO 2 Bonding at the PS lid T B =70 o C ( T g =90.6 o C ) bonded interface P B = 200 psi P C = 42 psi t B = 1 hr PS nanochannels 200 nm

Low T Fusion of Polymer Nanostructures Using CO 2 Low T Fusion of Polymer Nanostructures Using CO 2 55 PLGA lid T g, bulk = 48.3 o C 50 bonded interface 42.7 o C 45 Tg , oC 40 40.4 o C 35 30 200 nm 25 16.8 nm PLGA nanochannels 20 0 5 10 15 200 205 210 T B =35 o C, P B = 0.79 MPa Depth , nm P C = 0.08 MPa, t B = 1 hr Y. Yang, and L.J. Lee, , The Ohio State University CO 2 Bonding at the Microscale Microscale CO 2 Bonding at the T B = 35 o C, P B = 100 PLGA psi ( T g = 42.4 o C ), t B = 4 hr Before CO 2 Bonding: After CO 2 Bonding: 5 � m 5 � m Diameter: 5 µm Diameter: 5 µm Height: 3.9 µm Height: 3.95 µm

Tissue Engineering Tissue Engineering http://www.nlm.nih.gov/medlineplus http://www.becomehealthynow.com/ popups/liver.htm /ency/imagepages/19194.htm Construction of Multiple Cell- Construction of Multiple Cell -Scaffold Complex Scaffold Complex ES cells in Scaffold # 1 CO 2 fusing 3D cell-scaffold complex NIH 3T3 cells in Scaffold # 2 slice view 3D view scaffolds NIH 3T3 cells ES cells

CO 2 CO 2 Effects on Human Effects on Human Mesenchymal Mesenchymal Stem Cells ( Stem Cells (hMSCs hMSCs) ) viability adhesion proliferation Before CO2 exposure 20 � m 50 � m 100 � m After CO2 exposure @ 200 psi 20 � m 50 � m 100 � m Calcein AM - live cells DAPI - nuclei BrdU-labeled nuclei merged with EthD-1 - dead cells F-actin - cytoskeleton DAPI stained nuclei to show cells in proliferation stage CO 2 CO 2 Effects on Mouse Embryonic Stem (ES) Cells Effects on Mouse Embryonic Stem (ES) Cells After CO2 exposure @ 200 psi viability undifferentiation growth 20 � m adhesion 100 � m 100 � m Calcein AM - live cells 100 � m EB bodies EthD-1 - dead cells OCT-4 expression differentiation Early embryonic lineages Neurogenesis Cardiogenesis Myogenesis Pax-6: neuroectoderm Nestin: neuronal cells BMP-4: mesoderm Nkx2.5: cardiac Myf5: skeletal muscle muscle cells cells Scale bar: 20 � m

Nanofactory Nanofluidic Nanofluidic Protein Drug/Gene Delivery Separation Testbeds Super/Subcritical Manufacturing Self/Dynamic Manipulation Micro/Nano Assembly Fluidics Nanofiber Synthesis Fluids Nano Nano Core Technology Platform Thrust Areas ( Nanoengineering, Multiscale Modeling, Biocompatibility ) Building Blocks ( Functional Polymers, Biomolecules, Nanoparticles ) Applications of Nanofluidics in Drug Delivery and Genetic Engineering • Nanoneedle array cell patch for ex vivo gene delivery - electrophoretic nanofluidic • Nanofactory for production of multifunctional nanoparticles for in vivo gene delivery

Nanonozzle Cell Patch for Nanonozzle Cell Patch for Ex Vivo Ex Vivo Gene Gene Delivery Delivery (Electrophoretic ( Electrophoretic Nanofluidics Nanofluidics) ) Cell Suspension Loading Coiled 2 1 DNA Stretched Air Bubble DNA Injection Cell Cell Gene Delivery 80nm 80nm Through Nanoneedle Array Cell Patch Transformed Cell Nanonozzle Separation and Collection Array Small pore end Small pore end 2 � m 2 � m Mild electric shock to open cell membrane 1 2 Electrophoresis to deliver gene Fabrication of Nanotip Nanotip/nozzle Array by /nozzle Array by Fabrication of Sacrificial Template Imprinting (STI) Sacrificial Template Imprinting (STI) A Image Guide Differential Etching Nanotip Array B B Replica Molding 50 � m PDMS C 5 � m C Daughter Mold Casting Molding D D Sacrificial 5 � m Template E Spin Coating 5 � m E Polymer Nanonozzle Array 3 � m

��� � � ��� ��� ��� ��� ��� ��� ��� ��� ��� ���������� �������������� � � Dynamic (Electric/Magnetic) Assembly in Nanochannels EOF/EP 200nm - - - - - 50 nm + + + + + R - - + + + + + - - - - - Micro-channel Immobilized Mobile Drag Wall cations effect anions Silica Silica N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N + N + N + N + N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ - - - - - - SO 3 SO 3 SO 3 SO 3 SO 3 SO 3 - - - - - - - - - - - - SO 3 SO 3 SO 3 SO 3 SO 3 SO 3 SO 3 SO 3 - - - - SO 3 SO 3 SO 3 SO 3 - - - - SO 3 SO 3 SO 3 SO 3 - - - - SO 3 SO 3 SO 3 SO 3 - - - - SO 3 SO 3 SO 3 SO 3 - - - - SO 3 SO 3 SO 3 SO 3 N+ N+ N+ N+ N+ N+ N+ N+ SO 3 SO 3 SO 3 SO 3 N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N + N + N + N + N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ N+ - - - - - - - - - - - - - - - - - - - - - - - - PMMA PMMA PMMA S. Wang, C. Zeng and L.J. Lee, Adv. Materials 2005 Dynamic Assembly within Converging Nanochannels d microspher e D s , channel 0 . 0025 d 0 . 0025 C=0.000265% � : converging angle D

Dynamic Assembly within Converging Nanochannels sharp end large end Electrophoretic Migration of � -DNA through Nanonozzle Array, D s = 200nm, 20V/cm Nanonozzle Array Nanofluidic Support film edge Platform Donor side Acceptor side 100x Oil immersed Objectives

Recommend

More recommend