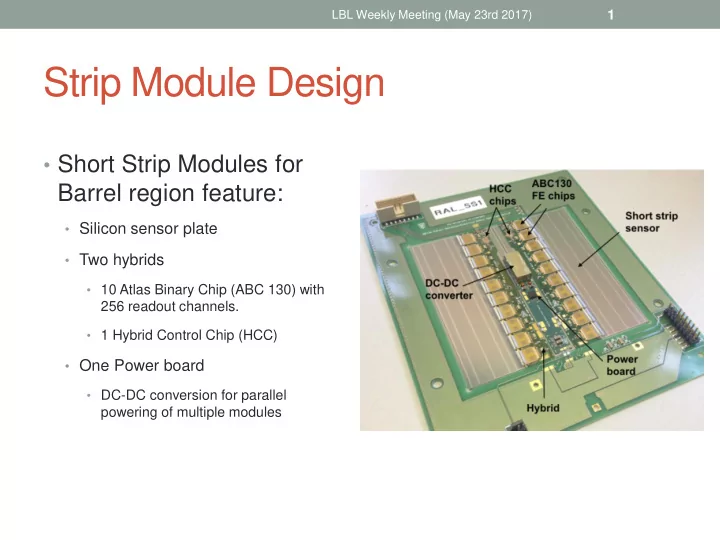

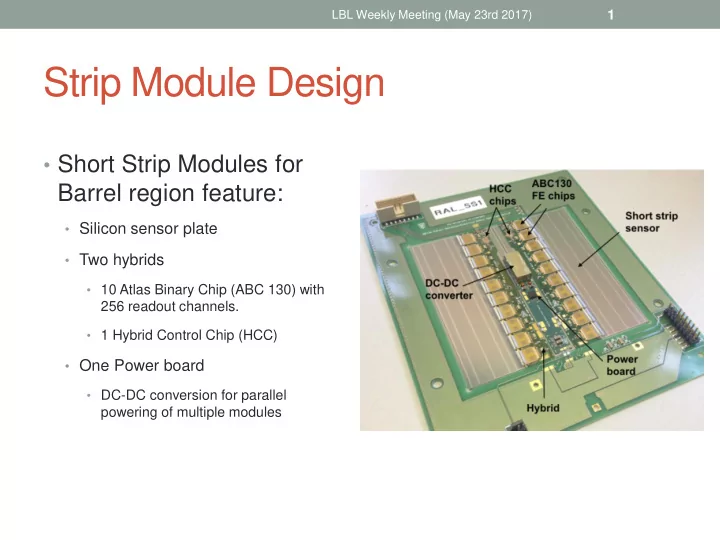

LBL Weekly Meeting (May 23rd 2017) 1 Strip Module Design • Short Strip Modules for Barrel region feature: • Silicon sensor plate • Two hybrids • 10 Atlas Binary Chip (ABC 130) with 256 readout channels. • 1 Hybrid Control Chip (HCC) • One Power board • DC-DC conversion for parallel powering of multiple modules

2 Metrology

3 Confocal Microscopy • Developing Metrology using the confocal microscopy system. • White light is refracted and focused such that each color focuses at different heights. • Measuring reflected lights color gives the height.

4 Metrology Process • Attempting to follow the methodology from Brookhaven • Scan 5 lines along the sensor and 3 lines along the tops of the chips. • Fit the bowing of the hybrid and the bowing of the sensor. • Extract chip heights X Y

5 Problem with Glass Chips • The measurements taken on the glass chips are not accurate • Heights under the glass is recorded. • Refraction from glass shifts the measurement higher. Top of glue dot Hybrid under glass chip Hybrid between chips

6 Electrical Module Construction

7 Electrical Module • We had constructed 2 hybrids, each with 10 working readout chips, and 1 control chip. • All testing and DAQ was successful. Ready to be put onto a sensor. • Hybrids are picked up by the chips and glued to sensor overnight.

8 Module Construction • One hybrid connected easily. • Second hybrid had a chip come loose, under closer inspection 6 chips were loose. • These were all ultimately replaced.

LBL Weekly Meeting (May 23rd 2017) 9 Loose Chip • Silver epoxy connected with chip but not well with hybrid • Initial height of glue dots are specified to be 120 microns from tooling. • Chips are then pushed onto hybrid to squish glue down to 80 microns high. • Appears that chip barely made contact with hybrid.

LBL Weekly Meeting (May 23rd 2017) 10 Metrology of Module • Measurements taken along hybrid and chips with SmartScope. • Glue dot height is calculated Loose Chips (hybrid 1) by: • Fitting hybrid with 2 nd order polynomial • Subtracting fit and chip width from measured chip height. • Two points on each chip measured, allowing the Replaced Chip slope to be calculated.

11 Chip Metrology • Mapped out entire back side of removed chip on confocal table. • Able to map out 900,000 data points 10 microns apart in ~5 minutes • Measurements with 50nm resolution in 10 micron steps in X-Y

LBL Weekly Meeting (May 23rd 2017) 12 Module Construction (cont.) • All readout channels are connected to sensor with bonds (5120 readout channels. • 4 rows of 64 bonds per chip arching over each other to connect to sensor

13 Bonding to frame and HV • Connect biasing bonds from hybrids to sensor. • LV ground and HV ground are shorted together through the Stealthy Bond Pad HCC so that leakage current can be measured. • In the future this will be through the AMAC chip on the powerboard.

14 Mapping out module Raw Data (darkness is height) • Mapped entirety of module on confocal table. • Should be able to clearly see wire bonds and roughly see ASIC patterning and the strips themselves (very roughly). • Scans measure 1.8 mm lines within 500 micron focal window • Requires merging of data in Z and Y directions Bond feet and top Tops of wire bonds of ABC

15 First Results • Image shows backside of chip and traces on hybrid. • Merging can be greatly improved by taking into account the brightness of each measurement

16 Next Steps • Actually apply high voltage to the sensor and test our first module! • Quantify the noise on the module, then add a power board to measure the differences in the noise.

Recommend

More recommend