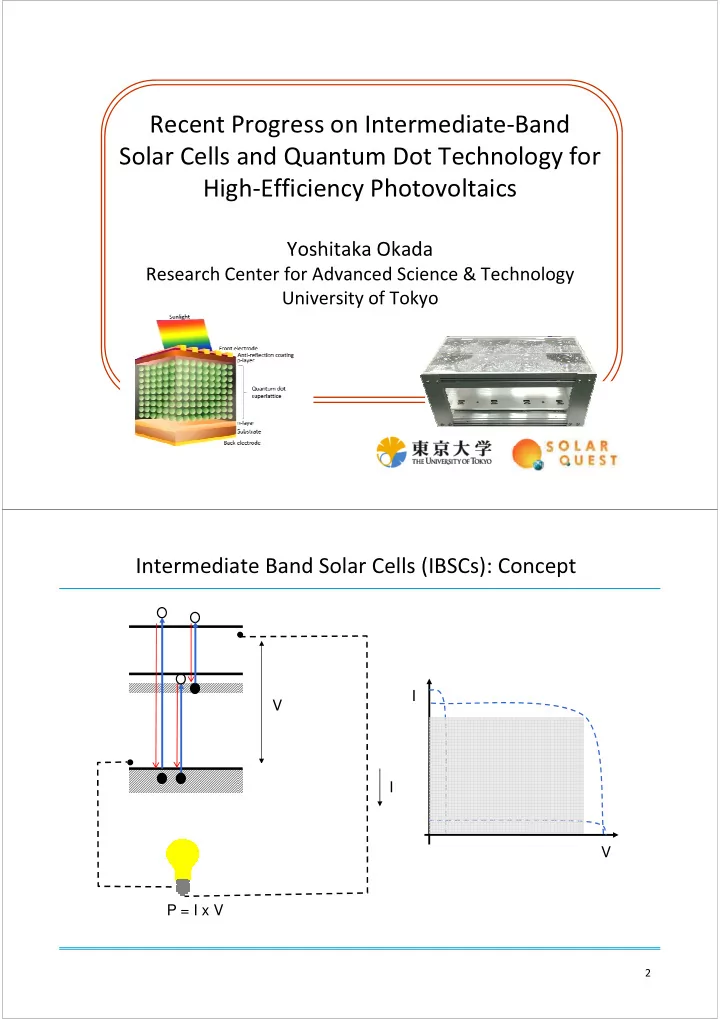

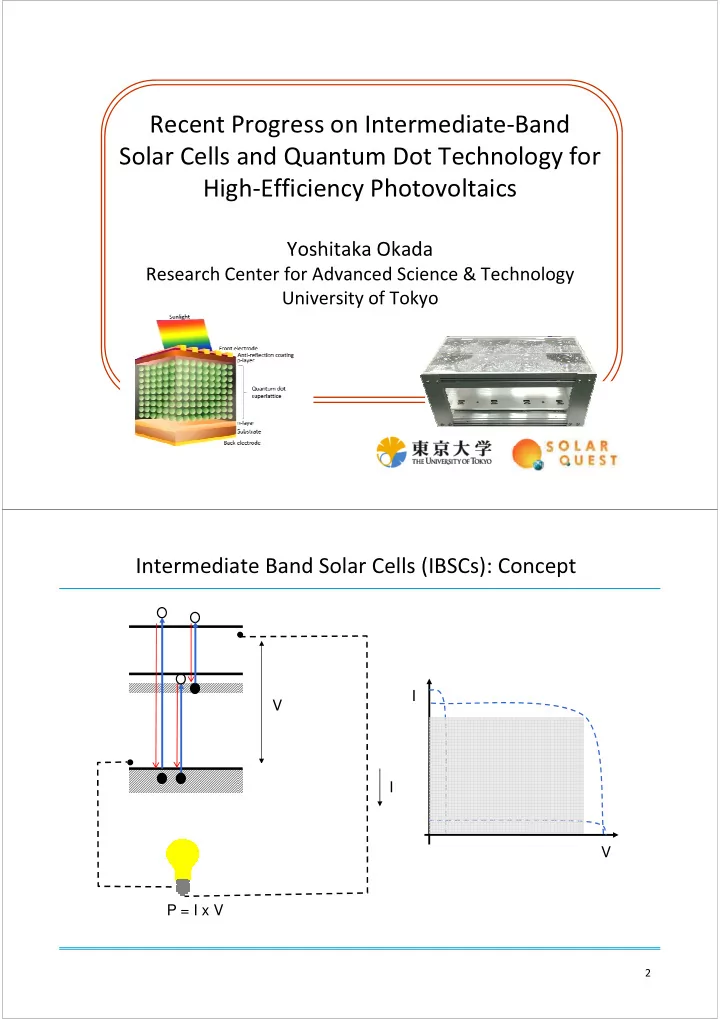

Recent Progress on Intermediate-Band Solar Cells and Quantum Dot Technology for High-Efficiency Photovoltaics Yoshitaka Okada Yoshitaka Okada Research Center for Advanced Science & Technology University of Tokyo Intermediate Band Solar Cells (IBSCs): Concept I V I V P = I x V 2

Quantum Dot Intermediate Band Solar Cells (QD-IBSCs) In(Ga)As/(Al)GaAs InAs/GaAsP energy gap (eV) 1 63% E IV (eV) E g =1.9 eV E CI =0.7 eV CB-IB ener 0.5 0.5 E 60 60 50 GaAs 40 30 InAs QD 20 CB 0 1.5 2 2.5 3 CB-VB energy gap (eV) E g (eV) 10 70 Efficiency (%) miniband η = 47% (1sun) η = 63% (Maximum concentration) VB 3 InAs/GaNAs Strain-Compensated QD-IBSC 50 stacks of InAs/GaNAs QDs • Good size uniformity and no dislocations are achieved by strain compensation. → QD diameter: 24.6nm height: 4.7nm Cell size Size uniformity: 11.1% 3mm × 5mm Sheet density: 5.0x10 10 cm -2 R. Oshima et al, Physica E 42 (2010) 2757 4

InAs/GaNAs Strain-Compensated QD-IBSC I sc increases linearly up to ~ 50 layers. Drop in V oc saturates after ~ 30 stacks. 1.5 mA/cm 2 for 50 stacks V OC V OC I SC I SC FF FF Diode Diode η η (V) (V) (mA/cm 2 ) (mA/cm 2 ) (%) (%) (%) (%) factor factor 20 20 0.72 0.72 21.04 21.04 70.0 70.0 10.63 10.63 1.65 1.65 stacks stacks 30 30 0.67 0.67 22.33 22.33 70.76 70.76 10.59 10.59 1.67 1.67 stacks stacks 50 50 0.68 0.68 26.36 26.36 70.24 70.24 12.44 12.44 1.59 1.59 stacks stacks GaAs GaAs 0.94 0.94 20.26 20.26 77.74 77.74 14.80 14.80 2.00 2.00 SC SC R. Oshima et al, Physica E 42 (2010) 2757 5 IBSC Performance on QD Absorption Non-ideal QD-IBSC Conventional SC (low QD-IB absorption) area: (1-r a )A area: A Ideal QD-IBSC area: r a A Detailed-balance model: / ( 1 )( ) ( ) J q r G R r G R G R a CV CV a CV CV CI CI = − − + − + − ( ) G R r G R CV CV a CI CI = − + − Absorption ratio of IB S. Yagi et al. 2nd Innovative PV Symp. (Tsukuba, 2009) 6

IBSC Performance on QD Absorption 70 J sc /X (mA/cm 2 ) Concentration X x1 60 Detailed-balance analysis x100 x1000 50 Single gap cell � Increase in r a leads to increase in 40 J SC but decrease in V OC . 1.2 V oc (V) 1.1 � Efficiency is below reference cell V 1 1 without QD-IBSC at 1sun, r < 0.5. without QD-IBSC at 1sun, r a < 0.5. 0.9 Efficiency (%) 50 � High concentration drastically increases V OC and efficiency. 40 30 0 0.2 0.4 0.6 0.8 1 r a QD-IB absorption ratio r a Present status S. Yagi et al. 2nd Innovative PV Symp. (Tsukuba, 2009) 7 Pictorial Summary: Road to High Efficiencies ① ② Increase of efficiency in IB solar cells Small absorption Larger absorption Under concentration via IB states via IB states Photon management Constant Constant � Doping (impurity doping or photo-filling) is important to maximize net generation rate via QD-IB . Maximize � IBSCs work best under concentrated sunlight. 8

Effect of Doping and Sunlight Concentration Net carrier generation rate via IB [ × 10 +20 ] CB p-type Emitter (0.5 µ m) 10 1 sun IBSC (w/o doping) 1 sun IBSC (w doping) IB region (1 µ m) 1000 suns IBSC (w/o doping) G CI R CI 1000 suns IBSC (w doping) −3 s −1 ) IB Case 1. Undoped (intrinsic) Case 2. n-type doped Case 2. n-type doped IB /X (cm −3 N D = N I /2 G IV 5 R IV n-type Base (1 µ m) VB G * 0 0.5 1 1.5 Position, x ( µ m) K. Yoshida and Y. Okada, NUSOD 2012, Shanghai (2012) 9 Short-circuit current Open-circuit voltage Conversion efficiency 2 ) rt circuit current density/X (mA/cm 40 1.3 Open circuit voltage (V) 45 Efficiency (%) 1.2 30 40 GaAs control 1.1 IBSC w doping GaAs control GaAs control GaAs control GaAs control Short ci O IBSC w/o doping IBSC w/o doping IBSC w doping IBSC w doping IBSC w doping IBSC w/o doping IBSC w/o doping 1 1 10 100 1000 1 10 100 1000 1 10 100 1000 Consentration Concentration Concentration Concentration Ratio, X Concentration Ratio, X Concentration Ratio, X • IBSCs have non-linear dependence on concentration ratio. • Drop in open-circuit voltage of IBSC is reduced by high concentration ratio. • Photo-filling plays a important role to realize high efficiency. To realize high conversion efficiency, IBSC should operate under high concentration ratio. 10

Processing Developed at IES-UPM 11 InAs/GaNAs Strain-Compensated QD-IBSC QD-IBSC (50 layers) 50 nm, p+-GaAs (5e18) 150 nm, p+-GaAs (2e18) emitter 20 nm, i-GaNAs x50 QDs i-InAs, 2,0 ML (1000 nm) 20 nm, i-GaNAs 1000 nm, n+-GaAs (1e17) base 250 nm, n+-GaAs (1e18) buffer Substrate, n+-GaAs 21.2% 5800K Blackbody 20.3% 1.3 1.3 Open−Circuit Voltage (V) 15.7% 1.2 1.1 • In QD-IBSC, V oc and hence efficiency recover fast with GaAs Control IBSC concentration due to increased photo-generation rates 1 from IB to CB. 1 10 100 1000 Concentration Self-consistent device simulation 12

Long Carrier Lifetimes ( ~ 100ns) in InAs/GaAsSb QDs Increasing Sb in GaAsSb Calculated τ radiative 18% ( 84 ns ) 14% 10% ( 25 ns ) ( 4 ns ) 0% ( 1 ns ) K. Nishikawa et al, JAP 111 (2012) 044325 13 Long Carrier Lifetimes in InAs/GaAsSb Type-II QDs GaAs wall-inserted type-II InAs/GaAs QD recombination lifetime InAs GaAsSb GaAsSb Calculated Hole dwell time QD 1 ns 1 ps Calculated Sb 18% Sb 18% Sb 18% Sb 18% Hole dwell time τ dwell 0 1 2 3 4 5 GaAs wall GaAs thickness (nm) Optimal values of GaAs thickness: 2 ~ 3 nm = ℏ dwell τ Γ D. Sato et al, JAP 112 (2012) 094305 14

Long Carrier Lifetimes in Type-II QD System GaAs 50 nm GaAs 0.82 Sb 0.18 15 nm Inserted GaAs walls 2 nm and 12 nm GaAs 0.82 Sb 0.18 15 nm InAs QD GaAs 50 nm InAs/GaAs(2 nm)/GaAs 0.82 Sb 0.18 Type I InAs/GaAs ・・・ 4.6 ns (Delay time 10 ns) Sb 18% GaAs wall 0 nm ・・・ 94 ns (Delay time 90 ns) Sb 18% GaAs wall 2 nm ・・・ 220 ns (Delay time 90 ns) K. Nishikawa et al, MRS Fall Meeting, Boston 2012 15 InGaAs/GaAsSb Type-II QD-IBSC AuZn/Au マスタ タイトルの書式設定 GaAsSb (7 nm) 1 period InGaAs QDs (8.7 MLs) p + - AlGaAs window layer GaAsSb (2 nm) p - GaAs emitter layer GaAs (60 nm) GaAs 60 nm ・ Growth Temperature = 480 ° C --- In --- In 0.4 Ga 0.6 As QDs layers --- Ga As QDs layers --- 8 QD stacks 8 QD stacks ・ Growth Rate = 1.0 µ m/h ・ Growth interruption = 40 sec (high growth rate technique) ・ Growth Temperature = 480 ° C --- GaAs & GaAsSb spacer layers --- n - GaAs base layer ・ Growth Rate = 0.6 µ m/h ・ Growth Temperature = 580 ° C --- Other layers --- n + - GaAs buffer layer ・ Growth Rate = 1.0 µ m/h n + - GaAs (311)B substrate In Y. Shoji et al, IEEE-PVSC, Austin (June 2012) 16

InGaAs/GaAsSb Type-II QDs on GaAs (311)B マスタ タイトルの書式設定 Mean diameter: 54.1 nm Mean height: 5.6 nm Sheet density: 3.2 × 10 10 cm -2 (2 µ m x 2 µ m) Y. Shoji et al, IEEE-PVSC, Austin (June 2012) 17 InGaAs/GaAsSb Type-II QD-IBSC With anti-reflection coating マスタ タイトルの書式設定 Y. Shoji et al, IEEE-PVSC, Austin (June 2012) 18

(June 2011 ~ March 2014) 19 Summary 1. Higher current means more QDs and higher photon intensity (Concentration) � Strain-compensated (strain-balanced) growth gives high crystal quality of multiple stacks of In(Ga)As QD layers and good QD-IBSC characteristics. � Homogeneous, dense and ordered InGaAs QD 2D-arrays can be grown on GaAs (311)B. � Doping (impurity doping or photo-filling) and Concentration are important to maximize the net generation rate via QD-IB : � Higher density QD arrays and longer lifetimes (IB) are required for good photo-absorption. → InGaAs QDs on GaAsSb ? → InGaAs QDs on GaAsSb ? 2. Higher absorption means longer optical length � Need for efficient Light Trapping. → Rear surface texturing or scattering using metal nanoparticles. Thank you for your attention! 20

Recommend

More recommend