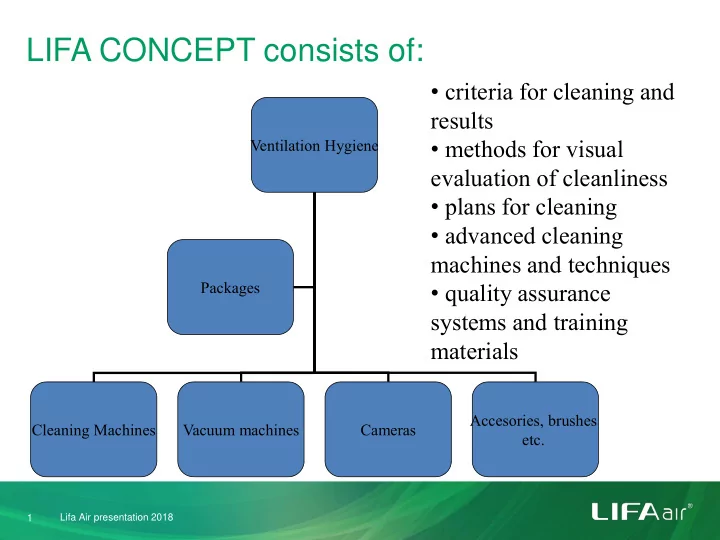

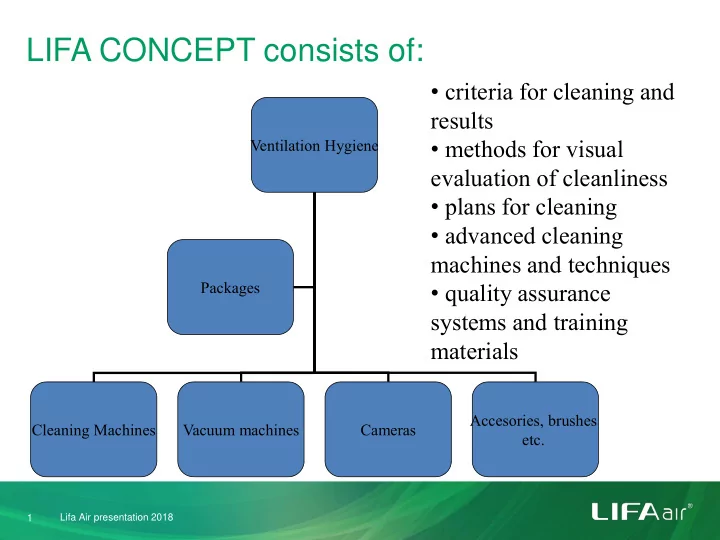

LIFA CONCEPT consists of: • criteria for cleaning and results • methods for visual Ventilation Hygiene evaluation of cleanliness • plans for cleaning • advanced cleaning machines and techniques Packages • quality assurance systems and training materials Accesories, brushes Cleaning Machines Vacuum machines Cameras etc. 1 Lifa Air presentation 2018

Path of the LIFA Cleaning Concept Consulting and guidance of customers The first Work document Inspection of need for cleaning ”Parallel” photos of Visual scale, robot aided video camera, comb and sampling method a photo of dirty duct Selection of cleaning devices: Brushing and/ air-jetting machine, brushes+accessories, negative air machine, disinfection devices etc Verification of the cleanliness, photos of visual scale, camera, etc, The second Work document perhaps not the same as in the first phase a photo of clean duct document for Documentation of the cleanliness, authorities if Added to the building documents for needed future use Lifa Air Oy Ltd. • Vellamonkatu 30 B, 00550 Helsinki, Finland • Tel: +358 9 394 858

Principles of cleaning concept Co n tro l a n d m a i n te n a n c e o f c l e a n l i n e s s o f H V A C s y s t V i s u a l i n s pe c ti o n No c l e a r c o n c u l s o i n A c c e pta bl e Ob j e c ti v e Ne e d s to b c l e an l i n e s s l e v e l m e as u re m e n ts Cl e a n i n g Cl e a n Do c u m e n ta ti o n Cl e a n i n

LIFA VENTILATION HYGIENE CONCEPT FOR ROUND AND RECTANGULAR AIR DUCTS AND AIR HANDLING UNITS The Concept consists of: • criteria for the cleaning and cleaning results • methods for the visual evaluation of cleanliness • plans for the cleaning • optimal choice of the cleaning method • advanced cleaning equipment and procedures • quality assurance systems and education material

Brushing machines, air blowing and liquid spreading equipment CombiCleaner 40 Hydmaster 40 Special Cleaner 25 Multi BIG FRAME MACHINES FOR DUCTS >300MM BRUSHING + AIR-JETTING SAME TIME SMALL FRAME MACHINES FOR DUCTS <400MM SpecialCleaner20 CombiCleaner15 AirJet 20 (+10) + driller shafts 4 types

Cleaning machines 2 • Hydmaster 40: brush rotation by Hydraulic motor, yet operation power 110/220V electric • CombiCleaner 40 + 15: brush rotation by compressed air motor, separate air hoses for spraying liquid/air-jetting whilst brushing • Special Cleaner 25 Multi: brush rotation by electric motor and cable, separate air hoses for spraying liquid/air-jetting whilst brushing • Special Cleaner 20: brush rotation by electric motor and cable • AirJet 20: for spraying liquid or air-jetting ( only, no brush) • Special Cleaner 2: brush rotation by electric motor and separate cable/shaft, 2-12 meter cables/shafts available

Vacuum/air cleaner units – negative air machines HepaClean 1100 AirClean 3500 HepaClean 2500 HepaClean 4000

Vacuum/air cleaner units – negative air machines

3 filters in same unit 1 PRE-FILTER BOX 2 F7 PARTICLE bag filter 3 G3/G4 Pre-filter mat 4 HEPA filter

Suction power vs. air flow • AirClean 3500: • air flow 3600 m3/h, suction power 840Pa • HepaClean 4000: • air flow 4600 m3/h, suction power 1000Pa • HepaClean 2500: • air flow 2600 m3/h, suction power 840Pa • HepaClean 1100: • air flow 300-1200 m3/h, suction power 800Pa

Video inspection equipment - DuctControl Manual: drop cam + glass fibre rod on reel, for small ducts - DuctControl Mini: remote controlled driveable camera robot, for ducts 16-70cm - DuctControl Cleaning Robot: compressor powering the brush motor, for ducts 20-70cm in height -New 2011: back camera included in both DC Mini and DC Cleaaning Robot

ACCESSORIES HYDMASTER AND COMBI CLEANER 40 3-brush-gear: for low (100- Y-gear for rectangular ducts 200mm) height but very wide >300mm in height – rotating 2 brushes at the same time (400-1000mm) ducts

Brushing machines, robots 8 kg, 18cm height 22 kg, Up to 70cm 35cm height Width 25cm, Up to 1,2m Cable length Cable length 30m 30m

CENTERING DEVICES Pneumatic centralizer for CombiCleaner 40, inflating+deflating remotely from switch Mechanical one for Hy40, SC25, CC15

Nozzles included in the price for CombiCleaner 15 + 40, AirJet Combi 20 and Special Cleaner 25 Multi : 1) disinfectant and liquid spraying (round-small ducts) 2) air-jetting nozzle (high volume) Accessory nozzles Y-nozzle (for big Ball nozzle (for small + Foam nozzle soft surface/flexible ducts rectangular ducts)

Brushes – 2 connection types 1) M12 screw connection (old type), for driller shafts, SC20 Soft – hard/stiff – combination=rect ducts – special vs. 2) Brush adapter connection for brushes with nylon center

Comparison of old vs. new type brushes inside duct New type Old type Disk in the center of the brush greatly enhances the speed of vacuum air flow

ACCESSORIES FOR VENTILATION CLEANING Y-Connection unit for HC2500/4000, To combine 2 vacuum units Exhaust Hose, clear plastic foil Telescope lifting set + flexible duct, 700 mm x 0,15 mm, 75 m roll properly attached into duct

Power supply/air compressors MACHINES THAT OPERATE ON NORMAL 1- PHASE ELECTRICITY HYDMASTER 40 SPECIAL CLEANER 25, 20, 2 HEPACLEAN 4000, 2500, 1100 AIRCLEAN 3500, 600 3-PHASE ELECTRICITY AIRCLEAN 7000 HYDROVANE COMPRESSOR MACHINES THAT REQUIRE COMPRESSED AIR Hydrovane rotary vane / COMBI CLEANER 40 + 15 lamell type compressor = AIRJET COMBI CONSTANT FLOW AIR SPECIAL CLEANER 25 Multi, only when SUPPLY IS NEEDED (not big spreading liquids or air-jetting with tank types) compressed air

Vacuum cleaners (dry dust vs grease sludge) H-certified always preferred ; also ”waste air” shower upwards) picture of washable bag filter inside

Sprayers for application of coatings and disinfectants FOR AIR DUCTS/PIPES Dry-fogging unit for open spaces Spray bottle 5l (manual) – ULV spray unit for all LIFA machines (electric)

Cleaning agents, disinfectants, coatings The ULV-technology = Ultra Low Volume is useful for quick disinfecting in the buildings and in ventilation systems. There are two basic methods: - Dry Fogging with by using Patriot PulsJet Fogger. - Damp mist by using MacroMist aerosol aggregat. These agents are peroxides. For ductwork we are using the "wet aerosol method". The chemical used must be approved by local authorities for HVAC use (formaldehyde and chlorine based chemicals is an absolute no- no), also be aware that some chemicals corrode the duct or kill the the galvanasation.

Personal safety, respirators, overalls etc

GREASE CLEANING CONCEPT

Grease Cleaning Concept • s uitable for all types of grease, soft or hard-burned and both round and rectangular up to 1,2m in size • unique capability of one machine capable of doing brushing, spraying chemicals and adsorbent granules all at the same time. • Lifa machines are the only ones powerful and durable enough to be able to rotate a brush in a grease duct is also a decisive factor.

Grease Cleaning Concept Different methods and techniques • Brushing (grease brush, cloth) • Spreading of chemicals and brushing • Spreading of oil adsorbent granules and brushing + air-jetting ALL AT THE SAME TIME combined in one equipment package: • Effective for all types of grease • In all sizes/shapes of ducts • Machines can be used in other work also

Grease set equipment SPREADING SIDE SUCTION SIDE Lifa HepaClean machine: unique Lifa brushing machine: unique filter options + combination capability of brushing and air- capability with superior vacuum jetting/spraying liquids at the power same time Lifa Preseparator Unit: Lifa Granule Sprayer: can be functionality and money attached to CombiCleaner 40, savings in less filter change Special Cleaner 25 Multi (also needs; attached to HC 2500, Hydmaster but then AirJet Combi HC 4000, AC 7000 20 is needed too)

Spreading side: Granule sprayer + Lifa brushing machine Special Cleaner 25 CombiCleaner 40 + 15 - pneumatic Can be attached to Hydmaster 40 also Granule Sprayer

Spreading side: Granule + chemical spraying • Hard grease that doesn’t come off with brushing need to be softened with grease detergent, foam best • Liquidy grease is adsorbed into oil adsorbent granule, then air-jetted and brushed out into preseparator

Nozzles for spraying chemicals and air-jetting • BASIC SET (incl. In machines): left ” liquid with back pressure valve”; right is ” high volume air” • ” foam nozzle ” • Y-nozzle small or big with bending arms: for air-jetting in rectangular ducts

Recommend

More recommend