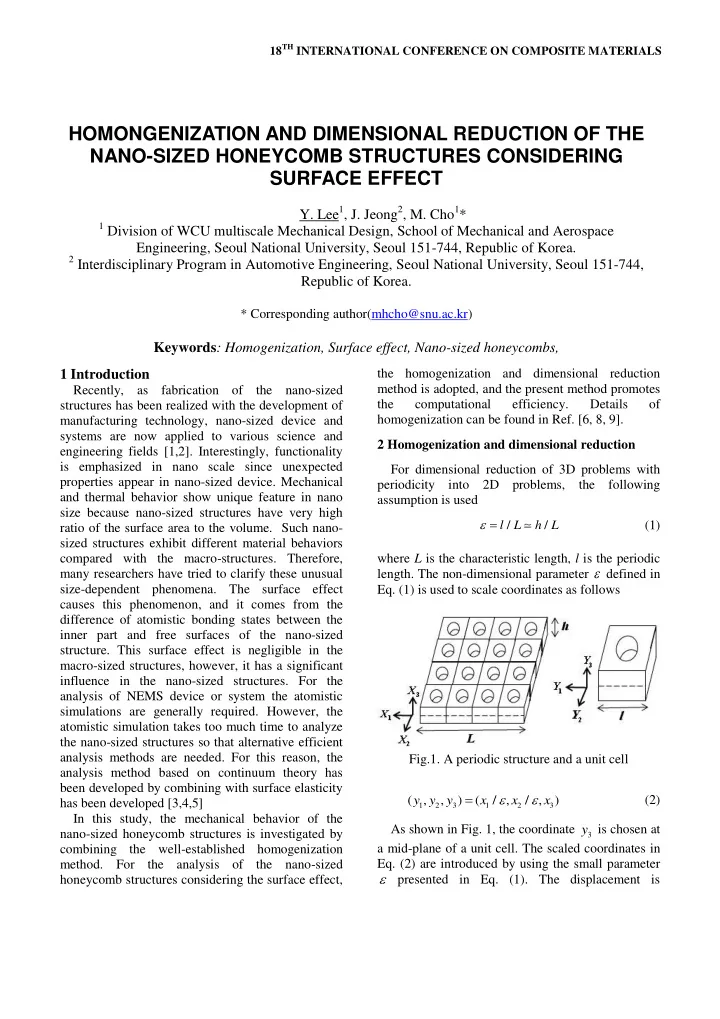

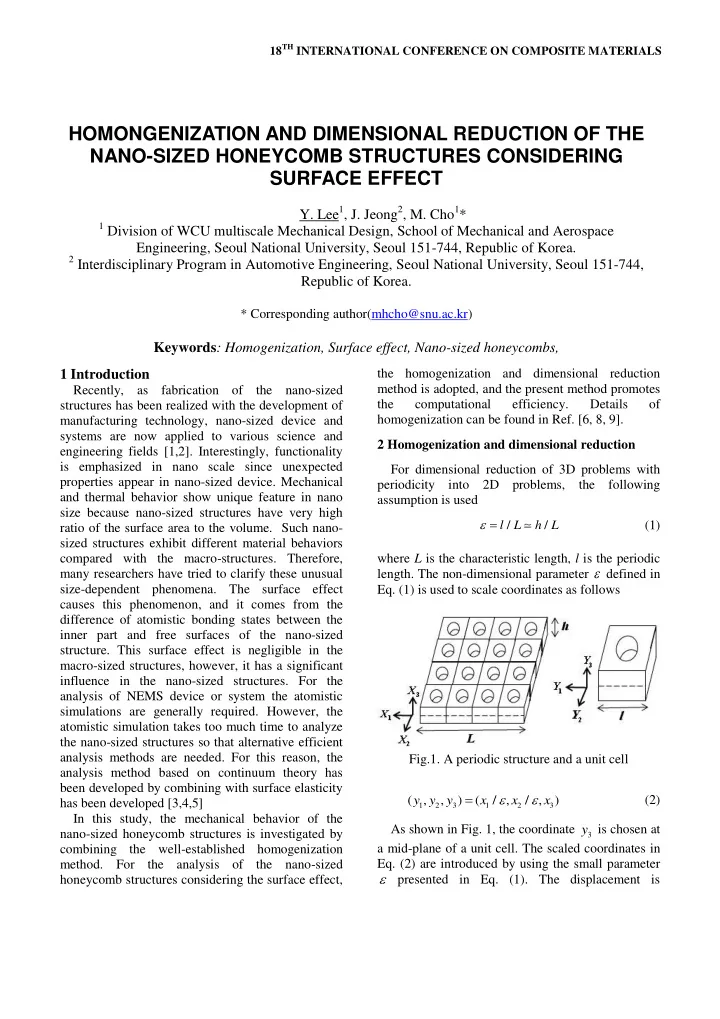

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS HOMONGENIZATION AND DIMENSIONAL REDUCTION OF THE NANO-SIZED HONEYCOMB STRUCTURES CONSIDERING SURFACE EFFECT Y. Lee 1 , J. Jeong 2 , M. Cho 1 * 1 Division of WCU multiscale Mechanical Design, School of Mechanical and Aerospace Engineering, Seoul National University, Seoul 151-744, Republic of Korea. 2 Interdisciplinary Program in Automotive Engineering, Seoul National University, Seoul 151-744, Republic of Korea. * Corresponding author(mhcho@snu.ac.kr) Keywords : Homogenization, Surface effect, Nano-sized honeycombs, 1 Introduction the homogenization and dimensional reduction method is adopted, and the present method promotes Recently, as fabrication of the nano-sized the computational efficiency. Details of structures has been realized with the development of homogenization can be found in Ref. [6, 8, 9]. manufacturing technology, nano-sized device and systems are now applied to various science and 2 Homogenization and dimensional reduction engineering fields [1,2]. Interestingly, functionality is emphasized in nano scale since unexpected For dimensional reduction of 3D problems with properties appear in nano-sized device. Mechanical periodicity into 2D problems, the following and thermal behavior show unique feature in nano assumption is used size because nano-sized structures have very high (1) l L / h L / ratio of the surface area to the volume. Such nano- sized structures exhibit different material behaviors compared with the macro-structures. Therefore, where L is the characteristic length, l is the periodic length. The non-dimensional parameter defined in many researchers have tried to clarify these unusual size-dependent phenomena. The surface effect Eq. (1) is used to scale coordinates as follows causes this phenomenon, and it comes from the difference of atomistic bonding states between the inner part and free surfaces of the nano-sized structure. This surface effect is negligible in the macro-sized structures, however, it has a significant influence in the nano-sized structures. For the analysis of NEMS device or system the atomistic simulations are generally required. However, the atomistic simulation takes too much time to analyze the nano-sized structures so that alternative efficient analysis methods are needed. For this reason, the Fig.1. A periodic structure and a unit cell analysis method based on continuum theory has been developed by combining with surface elasticity ( y y , , y ) ( x / , x / , x ) (2) has been developed [3,4,5] 1 2 3 1 2 3 In this study, the mechanical behavior of the As shown in Fig. 1, the coordinate y is chosen at nano-sized honeycomb structures is investigated by 3 combining the well-established homogenization a mid-plane of a unit cell. The scaled coordinates in Eq. (2) are introduced by using the small parameter method. For the analysis of the nano-sized presented in Eq. (1). The displacement is honeycomb structures considering the surface effect,

expanded with respect to , and the strain and stress ˆ ˆ ˆ 1 1 1 u x ( ) u ( ) x u ( ) x 3 k 0, E , are asymptotically expanded from the displacement x x x as shown in Eq. (3). For the 3D linear elastic (6) 2 0 u ( ) x problem, the governing equations (i.e. the 3 K , E E K K 0 equilibrium equation, the constitutive equation and i 3 3 i i 3 3 i x x the strain-displacement relationship) have the recursive form by employing the asymptotic In this study, the displacement solutions up to the 1 st order are considered, and the equivalent expansion method, and the traction free condition at the upper and lower sides and the periodic condition membrane and bending stiffness of a unit cell are at the lateral sides are applied. obtained from the relationship between the stress resultants (i.e. force and moment resultants) and the n 0 1 2 2 u ( ) x u ( , ) x y u x y ( , ) u ( , ) x y strains (i.e. strain and curvature) in the following n 1 0 0 0 1 equation. (3) e u ( ) e u ( ) e u ( ) e u ( ) y x y 1 1 0 0 1 1 ( ) x ( , ) x y ( , ) x y ( , ) x y . h h 1 A B N E , (7) T K By introducing two scales, the initial 3D elastic 1 M h h B D problem is separated into the macroscopic and microscopic problems. The homogenized stiffness 1 1 where N and M are in-plane force and moment are obtained by solving the microscopic problem. resultants, respectively and E and K indicate The solutions with respect to the leading order (- 1 st order) and the next order in the microscopic macroscopic strain and curvature, respectively. In problems are obtained directly from differential Eq. (7), the equivalent stiffness matrices are equations. The solutions to the 1 st order are expressed by decomposed into the rigid body displacement and warping displacement as follows E h , A C C kl ˆ 2 2 u u . (4) i i K h B y C C , (8) 3 kl Since the warping displacement cannot be solved K h 2 directly, the virtual work principle is used, and the D y C y C . 3 3 kl variational equation for the microscopic problem are written by where the linear operator is defined as ˆ 2 1 2 1 0, u dy u dy T , y , y 0 0 0 y y y 1 2 3 1 i dy C y K dy ij 3 , y y 0 0 0 . (9) j (5) y y y 2 1 3 i i k C E dy C dy . ij ijkl 0 0 0 y y y j j l y y y 3 2 1 If the Kirchhoff-Love plate assumptions in Eq. (6) 3 The surface elasticity for capturing the size- is applied, the dimensional reduction from 3D to 2D dependent elastic properties is accomplished. In order to consider the surface effect, the surface elasticity proposed by Gurtin and Murdoch [3] is expressed by

Recommend

More recommend