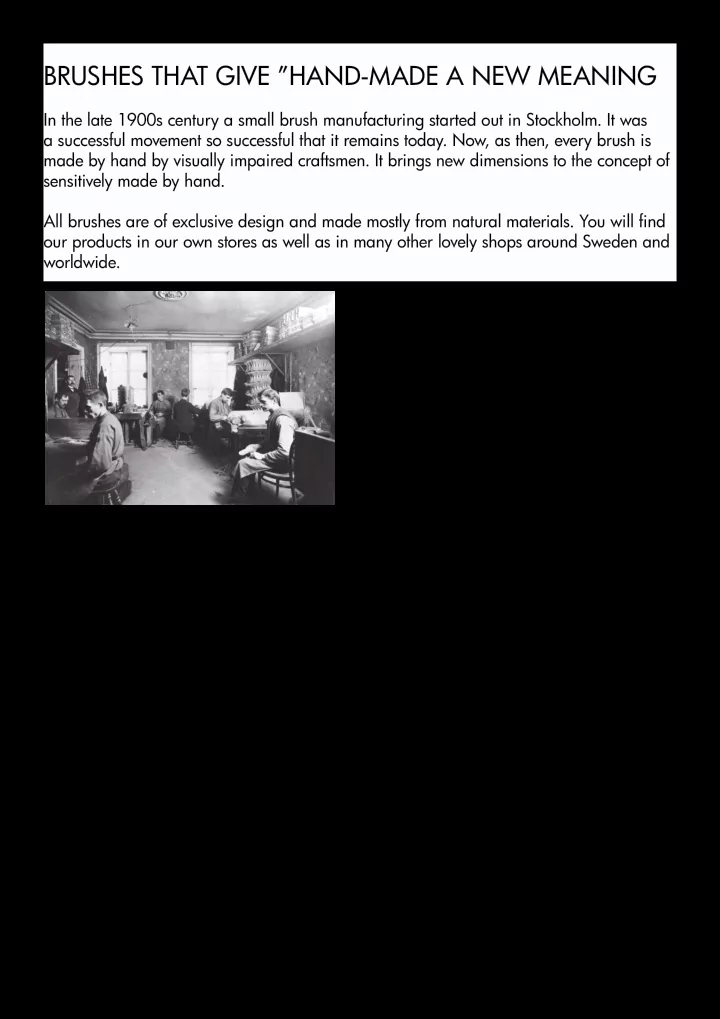

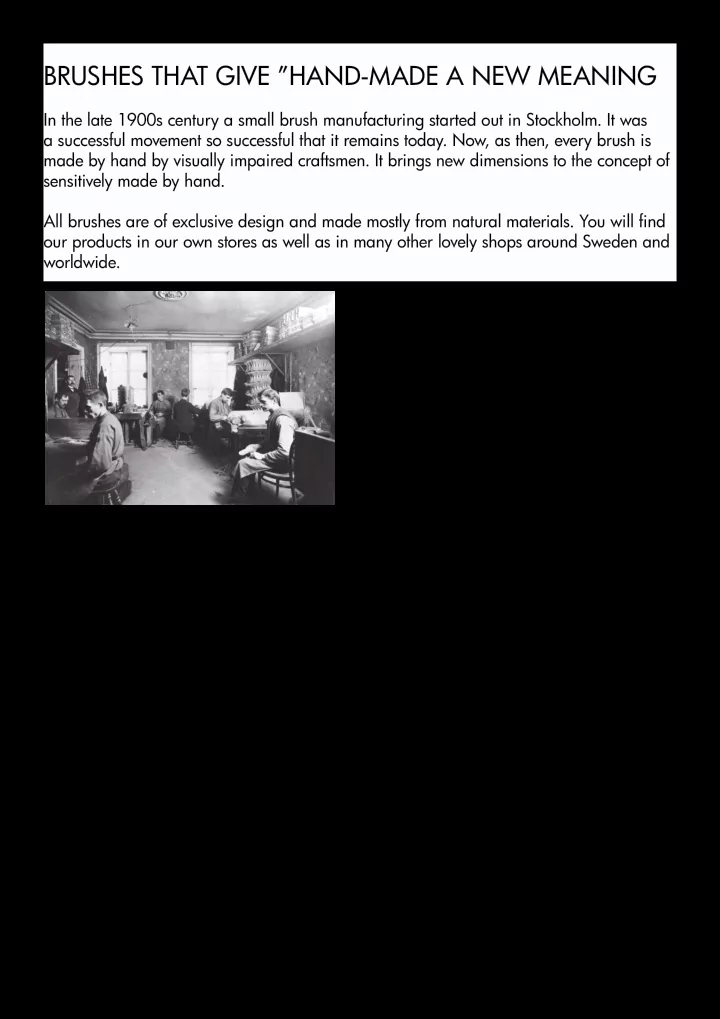

BRUSHES THAT GIVE ”HAND-MADE A NEW MEANING In the late 1900s century a small brush manufacturing started out in Stockholm. It was a successful movement so successful that it remains today. Now, as then, every brush is made by hand by visually impaired craftsmen. It brings new dimensions to the concept of sensitively made by hand. All brushes are of exclusive design and made mostly from natural materials. You will fjnd our products in our own stores as well as in many other lovely shops around Sweden and worldwide. History Iris hantverk has strong ties to and share their history with the Visually impaired organization in Sweden, SRF. In the 1900s century, Sweden began to change from being an agricultural country and develop into an industrial society. People moved to the cities - also this was the time when the labor movement emer- ged. In November 1870, Dr. Axel Beskov took the initiative of founding the Manilla School - a workhouse for visually impaired craftsmen in Stockholm. Initially there were nine people, most of them lived at the work- house. The salary was 75 percent of product sales. Part of that went to pay the accommodation. Work began 6 am and ended at 9 in the evening. In 1889 a group of visually impaired craftsmen founded a political independent organization, ”De blin- das förening”, whose purpose was to encourage, the otherwise much isolated group of visually impai- red, to actively participate in society in different social contexts such as musical events and lectures, but primarily to work for equal access to employment and live by their work. A large part of DBF work came to revolve around the development of support for the artisans and their ability to live off their work. In 1902 DBF decided that materials for brush binding and basket making would be purchased collectively in order to reduce prices and be sold to the visually impaired craftsmen for purchase price. In 1906 a property was bought on Majorsgatan 12, it accommodated a number of functions: offjce and library, brush binding factory, warehouse for raw materials, sales of raw material and a shop. These undertakings made the foundation for what Iris hantverk is today.

About us Today we are 14 employees at Iris Hantverk. The core of the business is the brush binding manufacturing at Sandsborgsvägen, Enskede – here 5 visually impaired craftsmen from different cultures make brushes according to an old Swedish tradition. We also work with visually impaired craftsmen in Estonia. Like us, they too have a history strongly connected to the visual impairments movement. The brushes are sold in our two shops in Stockholm and in our online store but also all over Sweden and the world through our wholesalers. We continue to supply individual artisans across the country with raw materials. Since August 2012, Richard Sparrenhök and Sara Edhäll run the company. In 2012 Socialdepartemen- tet withdraw the aid disbursed for depot activities for visually impaired craftsmen. That had been the main revenue for that function since the 1950s. Iris Hantverk’s owner at that time then decided to sell the company to us - both having worked for many years in the company and its management. We are both very glad to take over and operate on this company that holds so much history and tradition. In parti- cular, we appreciate the support visually impaired craftsmen have from De Blindas Väl whose generous contributions have made this website and webshop. We care much for the craftsmen and the survival of the brush binding manufactory. We believe that many like us appreciate the feeling and quality of a hand drawn brush made of natural materials. TRADITIONAL CRAFTSMANSHIP For over a hundred years, visually impaired craftsmen and women have been making brushes by hand, ac- cording to an old Swedish tradition. Now, as always, we focus on functional design an carefully selected na- tural materials. Combined with our expert craftsmans- hip, this gives every brush a unique function.

Brushes Our design has evolved through the years but the craftsmen still use the same time hono- ring techniques used for over a hundred years. The brushes are made by hand in mostly natural materials. A piece of wood is sawed, Holes for the bundle of bristles Now it’s time to attach each milled and sanded. The wood is drilled by machine. The holes individual bundle of bristles can then be lacquered or oiled. are small on the upper side to the base of the brush. The For example, in the renova- of the brush and is widened, fjnished wood, thread and tion of old silver brushes, the so that they are larger on the material in the form of animal wood must usually be precision other side - where the bristles hair, vegetable fjber or synt - manufactured by hand to fjt are. In a regular vegetable hetic material is put together. exactly in the silver bracket. brush it’s about 40 holes, a tailors brush have as many as 255 - all of which will be fjlled with material! The wire, usually a stainless Each individual bundle of When all the holes are fjlled steel wire, is pulled up in a bristles is placed in the wire with bristles the brush is cut loop through the narrowest loop and pulled into the arger and hackeled to get even end of the hole towards the hole - right into the ground. and smooth. It is done with a wider end. It is done with The bundle of bristles is cutting machine. Finished! the help of a hook that is picked by hand from the pack attached to a ring around the of material, or a machine is fjnger. used that dispenses out the right amount of material.

Care instructions OUR BRUSHES AGE BEAUTIFULLY We want our handmade brushes to continue beeing a joy to use a long time to come. With a little simple care, they will age beautifully. Clean the brushes with washing-up liquid and warm water. Let them dry bristles down, and from time to time oil the wood with mineral oil.

Recommend

More recommend