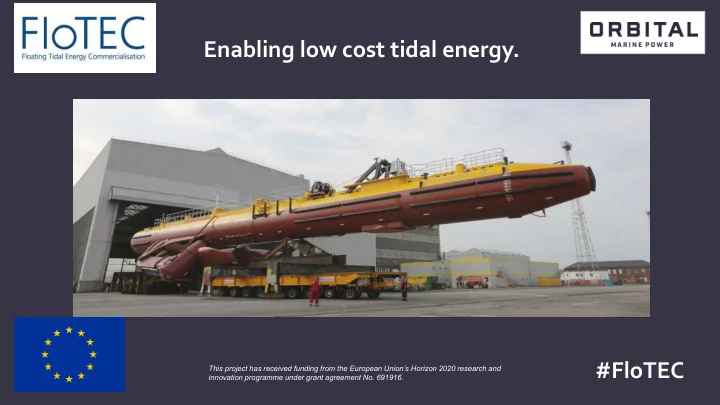

Enabling low cost tidal energy. #FloTEC This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 691916.

Grid connected test 15 years focused on engineering and testing the worlds most facility: European Marine Energy Centre advanced floating tidal technology. 100 years+ accumulated engineering and operational Company experience. Headquarters: Kirkwall, 26 staff covering technical, commercial and administration. Orkney Targeted patents granted and filed on key controlling IP. £30 million invested to date (including c.£6 million grant funding). Edinburgh office World’s first Further major Awarded World’s largest Company First major Further major grid connected investment: flagship tidal turbine incorporated: investment: investment: floating tidal 2012, 2014 and Horizon 2020 starts 2002 2006 2008 turbine: 2011 2015 funding operation: 2016

World’s largest operating tidal turbine – 2MW. 2 x 1MW nacelles with 16m rotor diameters. Stall regulated control. 500T turbine mass.

Standard Tidal Turbine Designs

Power distribution (P ∝ V 3 ) Current velocity profile 2/3 of total power in upper half of water column 50% depth 1/3 of total power in lower half of water column Greater turbulence and less power available closer to seabed Increase generator yield by positioning rotors in fastest flow regions near the surface.

Manufacturing process analogous to ship building. No dependency on high cost specialist construction vessels. Simplified offshore operations involving moorings and cable installation.

Maximise generator uptime by enabling fast response maintenance interventions. Minimise cost of repairs and service vessels via turbine design and marine operations.

Majority of turbine equipment and auxiliary systems located in hull. Hull accessible quickly via RIB at low costs (crew transit time <1hr @ EMEC). Hull accessibility demonstrated in up to 2m significant wave height (therefore accessible 90%+ of the year @ EMEC). SR1-2000 DEMONSTRATED MAINTENANCE CASE STUDIES Inverter module failure. Electrical drive and control faults. Dynamic cable re-splice. Turbine shut down. Most commonly occurring generic Non-standard cable repair requiring fault category resulting in most turbine shut down. Swapped out via RIB access downtime for offshore wind within 24hrs of intervention turbines. Single multi-cat vessel intervention to decision whilst turbine cut and re-splice subsea cable joint. remained on site. Demonstrated time to reset/resolve for SR1-2000: less than 12hrs turbine Completed in less than 48hrs from Turbine re-commissioned downtime using RIB style vessels. vessel mobilisation in up to 1.5m Hs and generating within 36hr. sea conditions. Total costs under £50k.

Ultimate mooring loads driven by controllable thrust generation (i.e. highly survivable in storm conditions). Loading variation due to surface waves manageable for generation across wide range of conditions.

2.2MW peak output. Best single tide = 6.3MWh. 21.7MWh+ in 24hrs generation = 45% capacity factor. 130MWh in 7 days of continuous generation = 39% capacity factor.

2.2MW peak output. Best single tide = 6.3MWh. 21.7MWh+ in 24hrs generation = 45% capacity factor. 130MWh in 7 days of continuous generation = 39% capacity factor. Provided 7%+ of entire Orkney electricity demand over 1 week of continuous generation.

2.2MW peak output. Best single tide = 6.3MWh. 21.7MWh+ in 24hrs generation = 45% capacity factor. 130MWh in 7 days of continuous generation = 39% capacity factor. Provided 7%+ of entire Orkney electricity demand over 1 week of continuous generation. Predictable source of generation.

2.2MW peak output. Best single tide = 6.3MWh. 21.7MWh+ in 24hrs generation = 45% capacity factor. 130MWh in 7 days of continuous generation = 39% capacity factor. Provided 7%+ of entire Orkney electricity demand over 1 week of continuous generation. Predictable source of generation. 450+ days on moorings. 380 days onsite in current install. 6,000hrs generation per nacelle. 3.2GWh+

Business Strategy Target Lowest Levelised Cost of Energy Concept Design (FEED) Objectives Product Specification Lessons Learned FloTEC target = <£200/MWh 1 st Arrays target = £150 - £180/MWh 100MW target = £120 - £150/MWh

Worldwide CfD Strike Prices Cost reduction trajectory rapidly towards cost parity with other 350 renewable generation sources. 300 250 100MW built capacity brings costs to £/ MWh 200 a level comparable with currently operating offshore wind capacity 150 awards of c.£150 / MWh. 100 50 1GW build out that lands the 0 Scotrenewables technology at £100 / MWh. The industry partners that deliver the initial projects will be best placed to capture long term benefits from rapidly expanding global markets. Awarded contracts Scotrenewables forecast

Enabling market for low cost tidal energy. #FloTEC This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 691916.

Generation #FloTEC This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 691916.

Manufacture

Key Innovations Legs attached above the waterline with all hull penetrations and leg actuation system above the waterline. Legs hinged axially to present nacelles and pitch hubs to surface for servicing at same time as improving structural load-paths. 360 ⁰ blade pitching allows for simplified forward and aft mooring arrangement and improved yield.

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No. 691916. www.flotectidal.eu

Recommend

More recommend