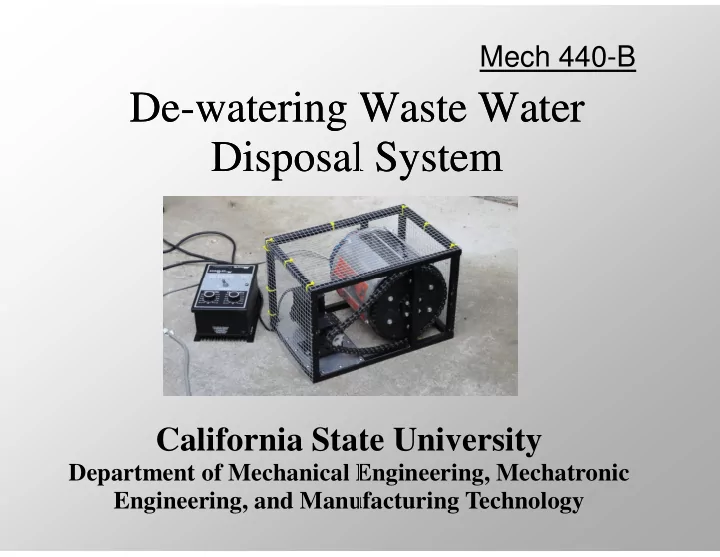

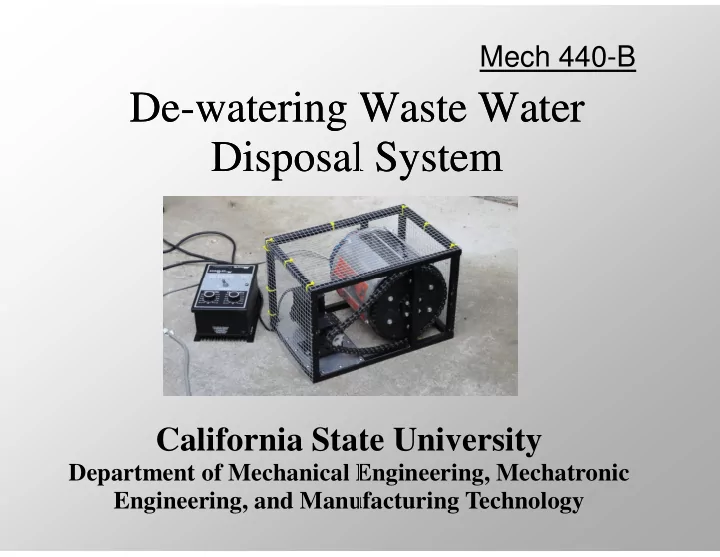

Mech 440-B De-watering W De-watering W ng Waste Water ng Waste Water Disposal Disposal al System al System California Stat tate University Department of Mechanical E l Engineering, Mechatronic Engineering, and Manu ufacturing Technology

Tea Tea eam eam Ghazali,Sami Schultz,Andrea Staton, James Zrodnikov, Yuriy

Spons Spons ponsors ponsors • Entrepreneurs Michael Bar arone and Jacob Mattos • Financial support and ment ntorship: The Chico Center for Entrepreneurship (CFE) • Ryne Johnson, Director of th f the Center for Entrepreneurship Entrepreneurship Faculty A Faculty A y Advisor y Advisor • Dr. Greg Watkins, P. E. • Professor of Mechanical Eng ngineering

Need and Goa Need and Goa oal Statement: oal Statement: Contaminated Well Water Scope of Evaporated project Solution Contaminated De-watering Waste Peltier solution Water Disposal Desalination System Solid Purified waste Water (for Water (for use) Need: The Peltier Desalination System ne needs an efficient and reliable method of disposing of the contaminated w waste water solution. Goal: To build and test a scale model of th f the system that receives a concentrated solution of contamina nants, boils away the excess water, and removes solid waste from the sy system. Changes: No changes to overall scope

Specifications for Specifications for for Scale Model for Scale Model • Must do: Quantitative Qualitative • Handle 10 gallons of contaminated • • Receives contaminated water from solution per day P Peltier Desalination System • Footprint - 12x18x12in • Removes the contaminants from the • system s • Moisture content less than 1% • Moisture content less than 1% • Vent steam (contaminants) away from • Vent steam (contaminants) away from • • t the pure water • Cost less than $2000 • Powered by standard household outlet • • Should do: • At least 2 year maintenance lif life • Weigh less than 100lbs • Would be nice: • Seals bag for easy disposal • Scale model connects to Peltier ier Desalination

Quantitative S Quantitative S Specifications Specifications and Ta and Ta Targets Targets Engineering Method/ Requirements Metric ic Target Condition Specifications Device Amount of Gallons s Bucket and >10 gallons 10% by salt contaminated Volume per day stopwatch per day solution solution Length, width, Inclusive of Dimensions Dimensions Inches Inches Tape measure Tape measure <12x18x12in <12x18x12in height all parts Completely Inexpensive Cost US Dollar ars Total cost of unit <$2000 assembled Water % Final state of Moisture content Experimentation <1% concentration moisture re waste Inclusive of Lightweight Mass Lbs. Scale <100 lbs all parts Without Maintenance Life Time Years Endurance test >2 years failure

Design S Design S gn Solution gn Solution

Design S Design S gn Solution gn Solution

System Co System Co omponents omponents Fabricated Parts: Tank, Frame, Blade, End Caps, Carrier Plate Mods. to sprockets Purchased Parts: Motor, Motor Controller Chain, Sprockets

Manufa facturing • Metal • Rolling the tank • Rolling the tank • Welding • Application of heaters: R s: RTV • Wiring

Tes Tes esting esting • List of experiments: – Physical size – Full cycle run and tempe perature logging – Endurance test (multiple le cycles)

Outco tcome Quantitative S Specifications Requirements Target Actu ctual Meets Does Not Meet � � � � 8 x 11 15 / 16 Maximum Dimensions <12x18x12in 12.5 x 18 � � � � Lightweight <100 lbs 47.4 .4 lbs Power Usage (Current � � � � <15 Amps 11.1 A Amps at 115 volts) � � � � Cost <$2000 $17 1711 � � � � >10 gallons per Processing Rate 10 gallons ns per day day � � � � Moisture Content <1% moisture >1.9% m moisture Qualitative Sp Specifications Requirement Meets Does Not Meet Receives contaminated water from Peltier � � � � Desalination System � � � � Removes the contaminants from the system tem Vent steam (contaminants) away from the e pure � � � � water � � � � 2 Year Life without maintenance

Final B Final B l Budget l Budget Description/Part t No. and Part QTY/Dimensions Actual Cost ($) vendor 1/17 hp DC Gearmotor 6470K71 Mcmaste ster-Carr 1 303.92 AC to DC Motor Controller RG501A - Mina inarik 1 247.60 Stainless plate 12"x12" 1 Stainless sheet 316 12"x42" 220.00 Stainless bar 316- 1" dia 12" Sheet (stainless) for end caps, 12 ga ga 12X12 2 Heaters SRFG-X07/10 Om mega 5 253.43 Relays Relays 3 3 SSR330DC25 Om SSR330DC25 Om mega mega Bearings Con 1638-2R RS 2 19.87 Nylon Machinable-Bore 60425K82 Mcmast ster-Carr 1 17.20 Sprocket Machinable-Bore Flat Sprocket 2299K58 Mcmaste ster-Carr 1 36.48 Roller Chain ANSI #50 6261K234 Mcmast ster-Carr 4' 17.12 I/O Expansion Pack Industrial Equipm ipment 900805 87.03 Tools and fasteners Local stores es N/A 217.60 Roll cylinde der 2 hours 124.78 Manufacturing Labor Stainless Steel We Welding 7 hours 165.00 Group’s labor (donated) $34.97/hr 1264 hrs 44202.00 Total 1710.03

Problems an and Solutions Problem: Short heater wires res interfere with tank rotation Solution: Tech shop staff ad added a wiring terminal and extended flexible le wires.

Problems and Problems and and Solutions and Solutions Problem: High moisture con ontent of salt Solution: Heat the system fo for a longer time Caveat: Heating causes sa salt to harden and adhere stronger to the cyl ylinder

Recommended D Recommended D d Design Changes d Design Changes Blade • Relax the moisture content requirement • Metal sprocket • Redesign of blade: • Redesign of blade: Bearings – Notch • Corrosion resistant bearings • Sophisticated heating system c capable of sensing temperature

Acknowle Acknowle ledgements ledgements • Entrepreneurs Michael Barone rone and Jacob Mattos • Ryne Johnson, Director of the the Center for Entrepreneurship • Faculty advisor Dr. Watkins ns • MMEM Department and Fa aculty: –Dr. Kallio –Dr. Kallio –Dr. Greene –Nick Repanich • Tech Shop –Steve Eckhart –Dave –Student Staff • Nathaniel Schultz • Industrial Equipment • Thomas Hydraulics • Padgett Precision Machine

Recommend

More recommend