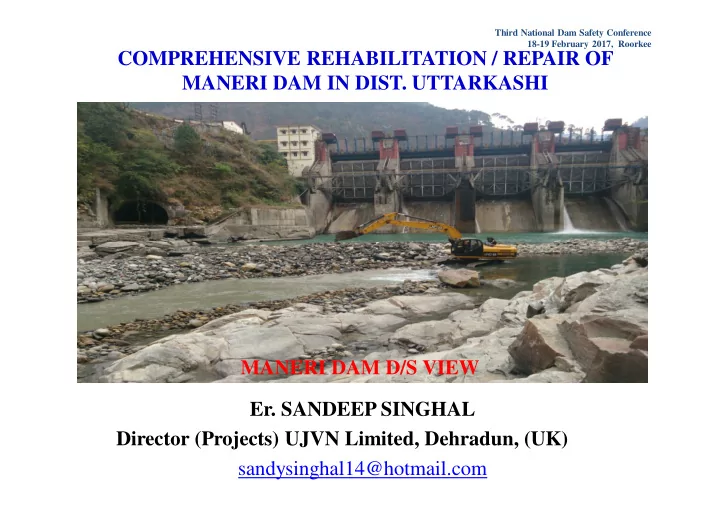

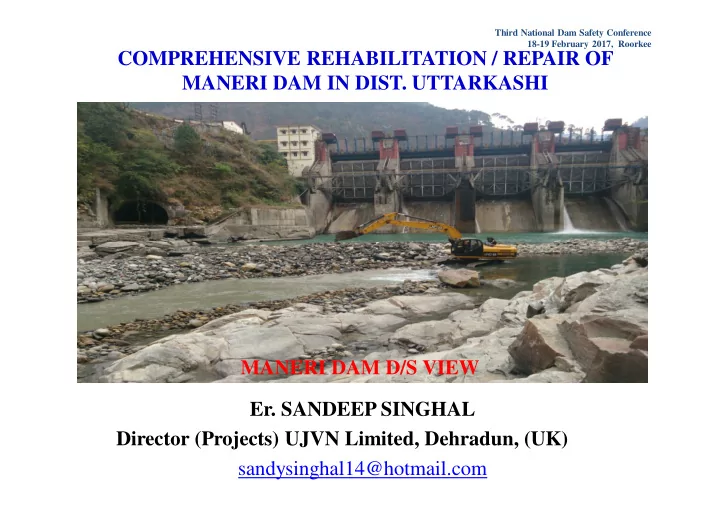

Third National Dam Safety Conference 18-19 February 2017, Roorkee COMPREHENSIVE REHABILITATION / REPAIR OF MANERI DAM IN DIST. UTTARKASHI MANERI DAM D/S VIEW Er. SANDEEP SINGHAL Director (Projects) UJVN Limited, Dehradun, (UK) sandysinghal14@hotmail.com

Third National Dam Safety Conference 18-19 February 2017, Roorkee ABSTRACT Severe floods in the rivers of Uttarakhnad in August 2012 and June 2013 badly damaged some hydro-electric power projects mainly in Bhagirathi and Alaknanda river valleys. Spillway of Maneri Bhali Stage –I dam was damaged severely due to rolling boulders which resulted in heavy leakages downstream. In order to arrest leakages, temporary arrangements such as caulking of gates were undertaken. After the monsoon of 2014, comprehensive rehabilitation/repair of Maneri Dam was planned after studying damages of similar nature and treatment measures at other hydro electric projects. The spillway no-01 & 02 were extremely damaged, therefore the repair works of these spillways were planned on priority basis in two phases:

Third National Dam Safety Conference 18-19 February 2017, Roorkee • Repair work from the sill beam of stop log gates to the 2.00 mts downstream of sill beam of radial gates were planned by taking minimum shutdown of Power House. • Repair work in entire spillway glacis from 2.00 mts downstream of sill beam of radial gate were planned in running power house condition. Repair of entire roller bucket and realignment of the downstream training wall were also planned subsequently. PROJECT BRIEF • Maneri Bhali Stage-I (90 MW) Hydro electric scheme was planned in 1960s to harnesses the potential energy of water flowing down river Bhagirathi between Maneri and Uttarkashi. The power house of this project is generating approx. 455 MU energy annually (average generation from 2004-05 to 2014-15) since October, 1984.

Third National Dam Safety Conference 18-19 February 2017, Roorkee This Scheme comprises of:- • A 39 m high and 127 m long Concrete Gravity Dam across river Bhagirathi near Maneri with four numbers spillways gates of size 13 m width & 14.55 m high separated by 2m thick piers. The spillway gates are radial type fitted with electrically operated hoists. The energy dissipation is allowed by providing slotted roller bucket. • Intake structure comprises of three bays 9.00 m. wide with all weather channel on the left flank. A sedimentation tank with 08 hoppers 15.00m wide x 15.70 m length X 5.75 m deep, in 2 rows is provided to remove silt particles which are passed back to the river downstream of the dam through silt flushing tunnel.

Third National Dam Safety Conference 18-19 February 2017, Roorkee • A 8.631 km long and 4.75 m diameter circular concrete lined power tunnel. • A 69 m high and 11 m diameter underground surge shaft of restricted office type along with 316 m long and 6m diameter upper expansion chamber, 89.5 m long and 6m diameter lower expansion chamber. • About 456 m long single steel lined penstock of 3.8 m diameter having three branches of 2.5 m diameter just upstream of the power house • A surface power station near Uttarkashi, housing three Francis turbines of 30 MW capacity each, i.e. total installed capacity of 90 MW. The firm power is 38.23 MW.

Third National Dam Safety Conference 18-19 February 2017, Roorkee • The design discharge of the power station is 71.4m 3 /s. The difference in elevation between the barrage and the power station affords a design head of 147.5 metres and gross head of 180 metres. • Open tailrace channel about 120 m long joins river Bhagirathi at Uttarkashi EXTENT OF DAMAGES i ) Damages observed in Spillway gate no. 01 & 02:- • The sill beam of stop log gate and radial gate were washed out in approximately 6.00 m & 8.00 m length (out of 13 m) respectively. The flange of the remaining sill beams was completely damaged.

Third National Dam Safety Conference 18-19 February 2017, Roorkee • As both the sill beam were washed out in some length, therefore a cavity of about 6 m-7 m in length (along the piers) having a depth upto 2.00 m was created in between radial gate and stop log gate. The flood also damaged the spillway glacis on the right side and in the d/s of radial gate beam throughout its length & upto roller bucket in 3.00 m width with a varying depth of maximum 13.00 m. ii ) Damages observed in Spillway gate no. 03 & 04:- • The concrete in between stop log gate and radial gate was eroded due to high flood. The maximum depth of the erosion was in range of 0.25 m to 0.70 m. • The profile of spillway glacis was also damaged from 0.25 m to 0.80 m in depth.

Third National Dam Safety Conference 18-19 February 2017, Roorkee Photograph 01 (Damages in gate no-1)

Third National Dam Safety Conference 18-19 February 2017, Roorkee STUDY OF DAMAGES Considering the past history of damages in Maneri Bhali Stage-I dam following were the major reasons of damages: i. There is no check dam or hydro power project dam upstream of Maneri Dam, due to these rolling boulders in monsoon period hit the Maneri dam directly. ii. In the upstream side there is a turn in the river and shortest radius of the turn is towards the gate no.1. Due to this rolling boulders in monsoon season pass more through bay no. 1 in comparison to other spillways bays. iii. The width of roller bucket is converging towards downstream, therefore the training walls obstruct the desirable flow pattern and consequently damages occurred in the spillway structure and roller bucket.

Third National Dam Safety Conference 18-19 February 2017, Roorkee REHABILITATION/REPAIR WORKS EXECUTED IN GATE NO. 01&02 • The damaged sill beams of bay no 01, 02 & 03 were removed and replaced with the new ones of the same size. The spillway glacis were repaired with M60 grade concrete and 20 mm thick MS steel plate was fixed over the repaired surface. Activities Performed During Closure Period • Detailed planning of execution of repair works of three spillway bays from sill beam of stoplog gate to 2m d/s of sill beam of radial gate within minimum possible time was done. A period 36 days starting from 02/12/2014 to 07/01/2015 was finalized for closing the Power House of MB-I HEP located at Tiloth in District Uttarkashi. Following activities were performed in sequential order to complete the works: • Creation of bund in front of spillway bay 1, 2 & 3 to divert water through spillway no. 4.

Third National Dam Safety Conference 18-19 February 2017, Roorkee • Dismantling damaged mild steel sheets previously placed over spillway concrete profile. • Damaged & remaining sill beams of stop log gate and radial gate were removed. • Dismantling of concrete so as to get a minimum thickness of 250 mm of new concrete and a cover of 200 mm over the reinforcement. • Drilling hole of 600 mm depth and 32 mm dia in staggered manner in parent concrete for fixing anchors. • Fixing 25 mm dia Fe 500 TMT bars in drill hole with grouting material for anchorage of reinforcement as well as dowel bars for fixing of MS plates. • The reinforcement was laid with 20 mm dia bars @ 150 c/c keeping the top cover of 200 mm. Where the cavity was more than 80 cm deep, reinforcement was provided in intermediate layers also keeping the top cover & bottom cover of 200 mm.

Third National Dam Safety Conference 18-19 February 2017, Roorkee • Applying bonding coat (BASF make) between old and new concrete. • Laying of concrete (ACC make Drycrete of M80 grade) in cavity between sill beam of stoplog gate and radial gate. • Fixing sill beams i.e. ISMB 300 (300 X 140) confirming to IS: 2062 (E250) with 20mm SS plate for Stop Log gates and Radial gates. • Laying concrete (ACC make Drycrete of M80 grade) up to final level as per the profile. • Fixing MS sheet (20mm thick with yield strength of 450 MPA) over the prepared concrete surface. • Grouting between steel plate and concrete by cutting notes through the steel plate & fixing the cut plate after grouting.

Third National Dam Safety Conference 18-19 February 2017, Roorkee To complete the repair works of spillway no 01 & 02 within stipulated period, all the pre-requisites such as manpower, material etc. were arranged before start of work. The works were taken up in 3 shifts continuously. The works were completed within 36days and Power House was restarted thereafter. Repair Works in Spillway Glacis • Repair works in spillway glacis is carried out from 2m d/s of radial gates during power house running condition. All activities were same as stated above only instead of M80 Drycrete , M-60 grade concrete was used. Concrete Mix Design Adopted For Works • Based on IS: 10262-2009 and IS: 456-2000 mix design for concrete is derived as below: a) Cement = 450 kg/m3 b) Water = 157 kg/m3 c) Silica fume = 25 kg/m3 d) Fine Aggregate = 598 kg/m3

Third National Dam Safety Conference 18-19 February 2017, Roorkee e) Coarse Aggregate = 1269 kg/m3 f) Chemical Admixture = 7.125 kg/m3 • The 28 days crushing strength of trial mix proportions for target M-60 grade of concrete was achieved as 68.9 N/mm 2 . Photograph 02 (Temporary Bund for channelization of river)

Third National Dam Safety Conference 18-19 February 2017, Roorkee Photograph 03 (Laying concrete in gate no-02) Photograph 04 (Grouting of MS Plate of gate no-2)

Recommend

More recommend