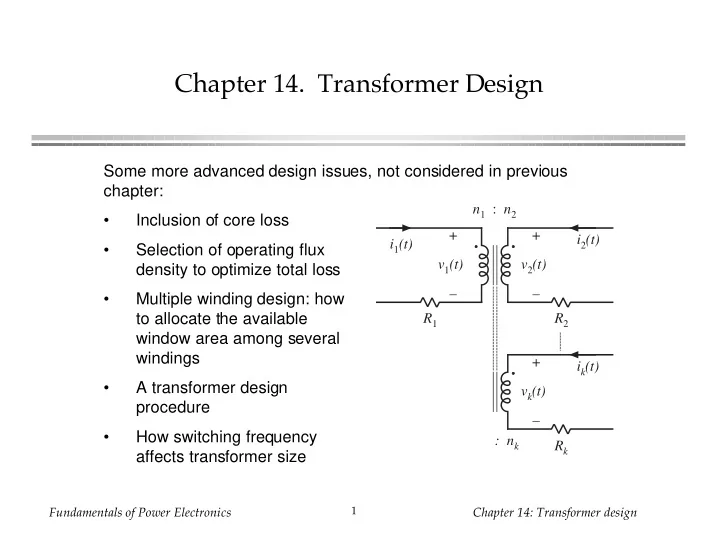

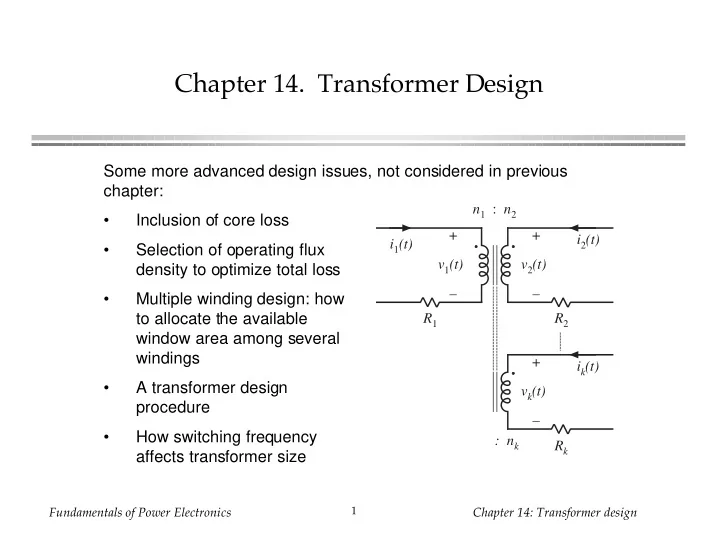

Chapter 14. Transformer Design Some more advanced design issues, not considered in previous chapter: n 1 : n 2 • Inclusion of core loss + + i 2 (t) i 1 (t) • Selection of operating flux v 1 (t) v 2 (t) density to optimize total loss – – • Multiple winding design: how to allocate the available R 1 R 2 window area among several windings + i k (t) • A transformer design v k (t) procedure – • How switching frequency : n k R k affects transformer size 1 Fundamentals of Power Electronics Chapter 14: Transformer design

Chapter 14. Transformer Design 14.1. Winding area optimization 14.2. Transformer design: Basic constraints 14.3. A step-by-step transformer design procedure 14.4. Examples 14.5. Ac inductor design 14.6. Summary 2 Fundamentals of Power Electronics Chapter 14: Transformer design

14.1. Winding area optimization Given: application with k windings n 1 : n 2 having known rms currents and rms current rms current desired turns ratios I 1 I 2 v 1 ( t ) n 1 = v 2 ( t ) = v k ( t ) n 2 = n k Core Window area W A rms current I k Core mean length per turn (MLT) : n k Wire resistivity ρ Q: how should the window Fill factor K u area W A be allocated among the windings? 3 Fundamentals of Power Electronics Chapter 14: Transformer design

Allocation of winding area { Winding 1 allocation α 1 W A Winding 2 allocation { α 2 W A Total window area W A etc. 0 < α j < 1 α 1 + α 2 + + α k = 1 4 Fundamentals of Power Electronics Chapter 14: Transformer design

Copper loss in winding j Copper loss (not accounting for proximity loss) is 2 R j P cu , j = I j Resistance of winding j is l j R j = ρ A W , j with length of wire, winding j l j = n j ( MLT ) A W , j = W A K u α j wire area, winding j n j Hence 2 ρ ( MLT ) 2 i j P cu , j = n j W A K u α j 5 Fundamentals of Power Electronics Chapter 14: Transformer design

Total copper loss of transformer Sum previous expression over all windings: + P cu , k = ρ ( MLT ) 2 2 I j n j Σ k P cu , tot = P cu ,1 + P cu ,2 + α j W A K u j = 1 Need to select values for α 1 , α 2 , …, α k such that the total copper loss is minimized 6 Fundamentals of Power Electronics Chapter 14: Transformer design

Variation of copper losses with α 1 For α 1 = 0: wire of winding 1 has zero area. Copper P cu ,1 tends to infinity P cu,k loss For α 1 = 1: wires of ..+ P cu, 1 P cu,tot . remaining windings have + 3 zero area. Their copper , u P c losses tend to infinity + 2 There is a choice of α 1 u , P c that minimizes the total copper loss α 1 0 1 7 Fundamentals of Power Electronics Chapter 14: Transformer design

Method of Lagrange multipliers to minimize total copper loss Minimize the function + P cu , k = ρ ( MLT ) 2 2 I j n j Σ k P cu , tot = P cu ,1 + P cu ,2 + α j W A K u j = 1 subject to the constraint α 1 + α 2 + + α k = 1 Define the function f ( α 1 , α 2 , , α k , ξ ) = P cu , tot ( α 1 , α 2 , , α k ) + ξ g ( α 1 , α 2 , , α k ) where Σ k g ( α 1 , α 2 , , α k ) = 1 – α j j = 1 is the constraint that must equal zero and ξ is the Lagrange multiplier 8 Fundamentals of Power Electronics Chapter 14: Transformer design

Lagrange multipliers continued Optimum point is solution of Result: the system of equations ξ = ρ ( MLT ) 2 Σ k n j I j = P cu , tot ∂ f ( α 1 , α 2 , , α k , ξ ) W A K u j = 1 = 0 ∂α 1 n m I m ∂ f ( α 1 , α 2 , , α k , ξ ) α m = ∞ Σ = 0 ∂α 2 n j I j n = 1 ∂ f ( α 1 , α 2 , , α k , ξ ) = 0 ∂α k An alternate form: ∂ f ( α 1 , α 2 , , α k , ξ ) V m I m α m = = 0 ∂ξ ∞ Σ V j I j n = 1 9 Fundamentals of Power Electronics Chapter 14: Transformer design

Interpretation of result V m I m α m = ∞ Σ V j I j n = 1 Apparent power in winding j is V j I j where V j is the rms or peak applied voltage I j is the rms current Window area should be allocated according to the apparent powers of the windings 10 Fundamentals of Power Electronics Chapter 14: Transformer design

Example PWM full-bridge transformer i 1 (t) i 2 (t) I } n 2 turns n 1 turns { } n 2 turns n 2 i 1 (t) I n 1 i 3 (t) 0 0 – n 2 I n 1 • Note that waveshapes (and hence rms values) i 2 (t) I of the primary and 0.5 I 0.5 I secondary currents are 0 different i 3 (t) I • Treat as a three- 0.5 I 0.5 I winding transformer 0 0 DT s T s T s +DT s 2 T s t 11 Fundamentals of Power Electronics Chapter 14: Transformer design

Expressions for RMS winding currents n 2 i 1 (t) I n 1 2 Ts = n 2 1 2 ( t ) dt I 1 = i 1 I D 2 T s n 1 0 0 0 – n 2 I 2 Ts 1 n 1 2 ( t ) dt = 1 I 2 = I 3 = i 2 2 I 1 + D 2 T s 0 i 2 (t) I 0.5 I 0.5 I see Appendix 1 0 i 3 (t) I 0.5 I 0.5 I 0 0 DT s T s T s +DT s 2 T s t 12 Fundamentals of Power Electronics Chapter 14: Transformer design

V m I m α m = Allocation of window area: ∞ Σ V j I j n = 1 Plug in rms current expressions. Result: 1 α 1 = Fraction of window area 1 + D allocated to primary 1 + D winding 1 α 2 = α 3 = 1 Fraction of window area 2 allocated to each D 1 + secondary winding 1 + D 13 Fundamentals of Power Electronics Chapter 14: Transformer design

Numerical example Suppose that we decide to optimize the transformer design at the worst-case operating point D = 0.75 . Then we obtain α 1 = 0.396 α 2 = 0.302 α 3 = 0.302 The total copper loss is then given by P cu , tot = ρ ( MLT ) 2 Σ 3 n j I j W A K u j = 1 = ρ ( MLT ) n 2 2 I 2 1 + 2 D + 2 D (1 + D ) W A K u 14 Fundamentals of Power Electronics Chapter 14: Transformer design

14.2 Transformer design: Basic constraints Core loss β A c l m P fe = K fe B max Typical value of β for ferrite materials: 2.6 or 2.7 B max is the peak value of the ac component of B ( t ) So increasing B max causes core loss to increase rapidly This is the first constraint 15 Fundamentals of Power Electronics Chapter 14: Transformer design

Flux density Constraint #2 v 1 (t) Flux density B ( t ) is related to the area λ 1 applied winding voltage according to Faraday’s Law. Denote the volt- seconds applied to the primary winding during the positive portion of v 1 ( t ) as λ 1 : t 1 t 2 t t 2 λ 1 = v 1 ( t ) dt t 1 This causes the flux to change from its negative peak to its positive peak. To attain a given flux density, From Faraday’s law, the peak value the primary turns should be of the ac component of flux density is chosen according to λ 1 λ 1 n 1 = B max = 2 n 1 A c 2 B max A c 16 Fundamentals of Power Electronics Chapter 14: Transformer design

Copper loss Constraint #3 • Allocate window area between windings in optimum manner, as described in previous section • Total copper loss is then equal to with P cu = ρ ( MLT ) n 1 2 2 I tot Σ n j k I tot = n 1 I j W A K u j = 1 Eliminate n 1 , using result of previous slide: 2 I tot P cu = ρ λ 1 2 ( MLT ) 1 K u 2 2 W A A c B max Note that copper loss decreases rapidly as B max is increased 17 Fundamentals of Power Electronics Chapter 14: Transformer design

Total power loss 4. P tot = P cu + P fe There is a value of B max Power that minimizes the total loss power loss C P fe o P tot p s p s e o r l l e o r s o s P tot = P fe + P cu C P cu β A c l m P fe = K fe B max B max Optimum B max 2 I tot P cu = ρ λ 1 2 ( MLT ) 1 K u 2 2 W A A c B max 18 Fundamentals of Power Electronics Chapter 14: Transformer design

5. Find optimum flux density B max Given that P tot = P fe + P cu Then, at the B max that minimizes P tot , we can write dB max = dP fe dP tot dB max + dP cu dB max = 0 Note: optimum does not necessarily occur where P fe = P cu . Rather, it occurs where dP fe dB max = – dP cu dB max 19 Fundamentals of Power Electronics Chapter 14: Transformer design

Take derivatives of core and copper loss 2 I tot P cu = ρ λ 1 β A c l m 2 ( MLT ) 1 P fe = K fe B max K u 2 2 B max W A A c dP fe β – 1 A c l m dB max = β K fe B max dB max = – 2 ρλ 1 2 I tot 2 dP cu ( MLT ) – 3 B max 4 K u 2 W A A c dP fe dB max = – dP cu Now, substitute into and solve for B max : dB max 1 β + 2 ρλ 1 2 I tot 2 Optimum B max for a ( MLT ) 1 B max = β K fe given core and 2 K u 3 l m W A A c application 20 Fundamentals of Power Electronics Chapter 14: Transformer design

Total loss Substitute optimum B max into expressions for P cu and P fe . The total loss is: β β 2 β + 2 ρλ 1 β β + 2 + β 2 I tot – 2 β + 2 ( MLT ) 2 β + 2 P tot = A c l m K fe 4 K u 2 2 2 W A A c Rearrange as follows: – β + 2 β β 2/ β 2( β – 1)/ β 2 K fe ρλ 1 2 2 I tot β β + 2 + β W A A c – β + 2 = 2/ β 2 2 β + 2 / β ( MLT ) l m 4 K u P tot Left side: terms depend on core Right side: terms depend on geometry specifications of the application 21 Fundamentals of Power Electronics Chapter 14: Transformer design

The core geometrical constant K gfe – β + 2 β β 2( β – 1)/ β 2 β β + 2 + β K gfe = W A A c – β + 2 Define 2/ β 2 2 ( MLT ) l m Design procedure: select a core that satisfies 2 K fe 2/ β ρλ 1 2 I tot K gfe ≥ β + 2 / β 4 K u P tot Appendix 2 lists the values of K gfe for common ferrite cores K gfe is similar to the K g geometrical constant used in Chapter 13: • K g is used when B max is specified • K gfe is used when B max is to be chosen to minimize total loss 22 Fundamentals of Power Electronics Chapter 14: Transformer design

Recommend

More recommend