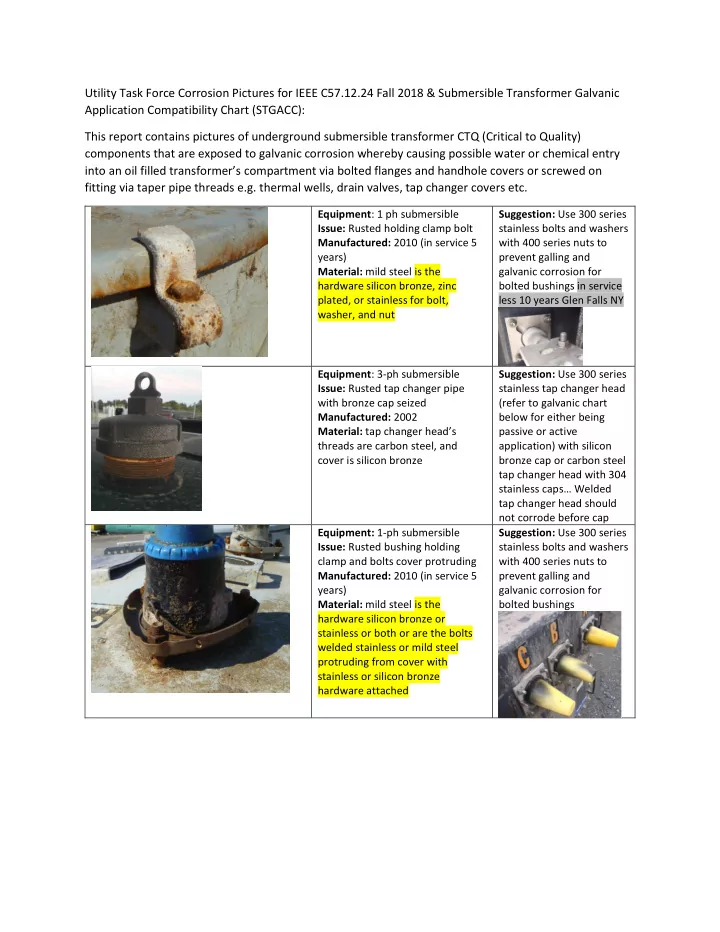

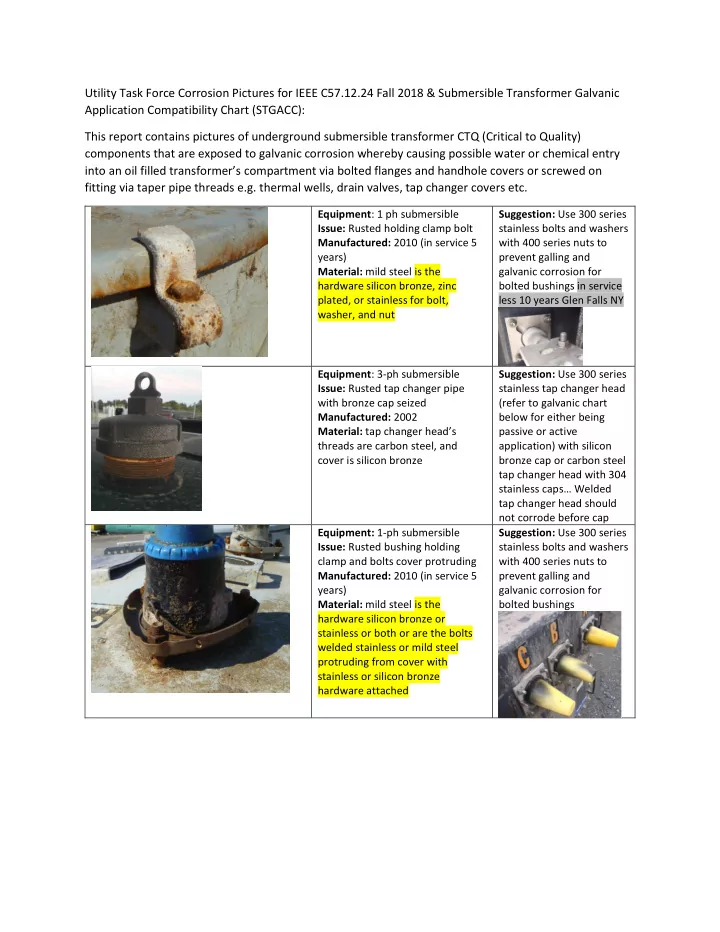

Utility Task Force Corrosion Pictures for IEEE C57.12.24 Fall 2018 & Submersible Transformer Galvanic Application Compatibility Chart (STGACC): This report contains pictures of underground submersible transformer CTQ (Critical to Quality) components that are exposed to galvanic corrosion whereby causing possible water or chemical entry into an oil filled transformer’s compartment via bolted flanges and handhole covers or screwed on fitting via taper pipe threads e.g. thermal wells, drain valves, tap changer covers etc. Equipment : 1 ph submersible Suggestion: Use 300 series Issue: Rusted holding clamp bolt stainless bolts and washers Manufactured: 2010 (in service 5 with 400 series nuts to years) prevent galling and Material: mild steel is the galvanic corrosion for hardware silicon bronze, zinc bolted bushings in service plated, or stainless for bolt, less 10 years Glen Falls NY washer, and nut Equipment : 3-ph submersible Suggestion: Use 300 series Issue: Rusted tap changer pipe stainless tap changer head with bronze cap seized (refer to galvanic chart Manufactured: 2002 below for either being Material: tap changer head’s passive or active threads are carbon steel, and application) with silicon cover is silicon bronze bronze cap or carbon steel tap changer head with 304 stainless caps… Welded tap changer head should not corrode before cap Equipment: 1-ph submersible Suggestion: Use 300 series Issue: Rusted bushing holding stainless bolts and washers clamp and bolts cover protruding with 400 series nuts to Manufactured: 2010 (in service 5 prevent galling and years) galvanic corrosion for Material: mild steel is the bolted bushings hardware silicon bronze or stainless or both or are the bolts welded stainless or mild steel protruding from cover with stainless or silicon bronze hardware attached

Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted pipe flange threads, stainless pipe plug on silicon bronze sampler seized carbon steel pipe flange Manufactured: 2002 and Teflon tape barrier Material: pipe flange is carbon steel, sampler is silicon bronze Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted pipe flange threads, stainless pipe plug on silicon bronze sampler seized carbon steel pipe flange Manufactured: Pending with Teflon tape barrier Material: pipe flange is carbon between different metals steel, sampler is silicon bronze … welded flange should not corrode before fitting and or sampling device service since for past 10 years see good example below Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted pipe flange threads, stainless pipe plug on sensor seized carbon steel pipe flange… Manufactured: Pending flange should not corrode Material: pipe flange is carbon before sampling device steel, sensor is stainless is the in service since for past 10 sensor 316 or 304… refer to years same as above galvanic chart

Equipment : 3-ph submersible Suggestion: Use 300 series Issue: Rusted carbon steel pad for stainless plate decal and decal plate screw being of same Manufactured: Pending material (refer to galvanic Material: pad is carbon steel, plate chart below for either decal is silicon bronze being passive or active application) Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted pipe nipple where stainless globe valve on drain valve is installed carbon steel pipe flange Manufactured: Pending (refer to galvanic chart Material: pipe nipple is carbon below for either being steel, drain valve is silicon bronze passive or active application) and silicon bronze globe valve on stainless steel… pipe nipple should not have corroded before valve… no tank welded components should corrode first. Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted nipple where drain stainless globe valve on valve is installed carbon steel pipe flange Manufactured: 2013 and silicon bronze globe Application: Sludge/High Polluted valve on stainless steel… Material: pipe nipple is carbon pipe nipple should not steel, drain valve and pipe plug is have corroded before silicon bronze valve… no tank welded components should corrode first. Equipment : 3-ph submersible Suggestion: Use some Issue: Galvanic corrosion all over epoxy coatings with zinc tank and cover + leaking drain rich primer which are valve drain valve is brass (or superior for underground equivalent), had leaks at the fitting applications. Use 304 with the tank or the pipe between stainless globe valve on the 2. Drain valve eliminated since carbon steel pipe flange few years and replaced with a plug and silicon bronze globe on top of cover valve on stainless steel Manufactured: 8 years in service; primer with powder top coat and (continues next page) Devtar (asphalt) on bottom of tank about 1 foot high Installed: Canada Northeast Removed: N/A Application: dry vaults or with little drainage water but many covered with water for some time

Material: copper bearing steel tank and cover; no external accessories such as PRV, sight gage, thermometer; surrounded with bare copper grounding wire which accelerate galvanic corrosion on the tank Was the water in the vault stagnant and/or salty? What are the effects of Devtar (asphalt) in an aqueous salty solution… does it affect the PH accelerating other types of corrosion e.g. pitting, chemical, bacterial, etc. Equipment : 3-ph submersible Issue: Rust or other corrosion showing where the terminals were bolted to tin plated neutral Manufactured: 2013 Installed: 2013 Removed: 2018 Application: Coastal Material: tin plated copper neutral was the connecting terminal tin plated Equipment : 3-ph submersible Issue: None: No Rust showing where terminal was bolted to tin plated neutral Manufactured: 2015 Installed: 2016 Removed: 2018 Application: Coastal Material: tin plated copper neutral, shows a tin plated 2-hole terminal lead

Equipment : 3-ph submersible Suggestion: Use 304 Issue: Rusted pipe flange threads, stainless pipe plug on pipe plug possibly seized carbon steel pipe flange… Manufactured: 2009 tank welded flange should Installed: 2009 not corrode before Removed: 2018 sampling device Application: Coastal Material: pipe flange is carbon steel, pipe plug is silicon bronze Equipment : 1-ph submersible Perfect Recommendation: Issue: None: No galvanic corrosion if user wants to continue where dissimilar metals touching; to use bronze valves, only rusting at tank bottom terminals, etc. and/or Manufactured: 2009; powder coat there’s no stainless version Installed: 2011 1024 Fossil Creek, of those terminals or Colorado components that exist on Removed: 2018; no maintenance the market…. A copper Application: Salt Water chloride bearing steel tank with Material: tank material mild steel welded stainless provision with welded stainless nut and tin-plated bronze provision and tin-plated bronze terminals all having fitting terminal; fitting barrier Teflon tape barriers with Teflon tape Equipment : 1-ph submersible Issue: Same as 1024 Fossil Creek only rusting at tank bottom Manufactured: 2001; powder coat Installed: 2002 6802 Autumn Ridge, Colorado Removed: 2012; no maintenance Application: Salt Water chloride Material: tank material mild steel; unsure if fitting had Teflon tape as a barrier Equipment : 1-ph submersible Perfect Recommendation: Issue: None: No galvanic corrosion if user wants to continue where dissimilar metals touching to use bronze valves, Manufactured: 1992; powder coat terminals, etc. and/or Installed: 1993 1213 Alameda St. there’s no stainless version Colorado of those terminals or Removed: 2018; no maintenance components that exist on Application: Salt Water the market…. A copper Material: tank material mild steel bearing steel tank with with welded stainless nut welded stainless provision provision and tin-plated bronze and tin-plated bronze terminal; fitting barrier Teflon tape terminals all having fitting barriers with Teflon tape

Equipment : 3-ph submersible Issue: Rust showing where terminals were bolted to neutral Manufactured: 2009 Installed: 2009 Removed: 2018 Application: Coastal Material: copper neutral Was the neutral blade tin plated, was the connecting terminal tin plated, and what type of hardware was used Equipment : 3-ph submersible Suggestion: Use stainless Issue: Sever pitting of the housing with stainless temperature gauge’s aluminum thermal well instead of housing aluminum with silicon Manufactured: 2009 bronze or brass thermal Installed: 2013 well screwing onto carbon Removed: 2018 steel tank pipe flange Application: Coastal Material: Aluminum housing with stainless steel screws on faceplate with brass/silicon bronze or brass thermal well as part of assembly; thermal well screwed into welded steel tank pipe flange. Equipment : 3-ph submersible Suggestion: Use stainless Issue: paint degradation flaking of housing with stainless the temperature gauge aluminum thermal well instead of housing; severe rusting around aluminum with silicon pipe flange bronze or brass thermal Manufactured: 2000 well screwing onto carbon Installed: 2002 steel tank pipe flange Removed: 2018 Application: Coastal Material: Aluminum housing with stainless steel screws on faceplate with brass/silicon bronze or brass thermal well as part of assembly; thermal well screwed into welded steel tank pipe flange.

Recommend

More recommend