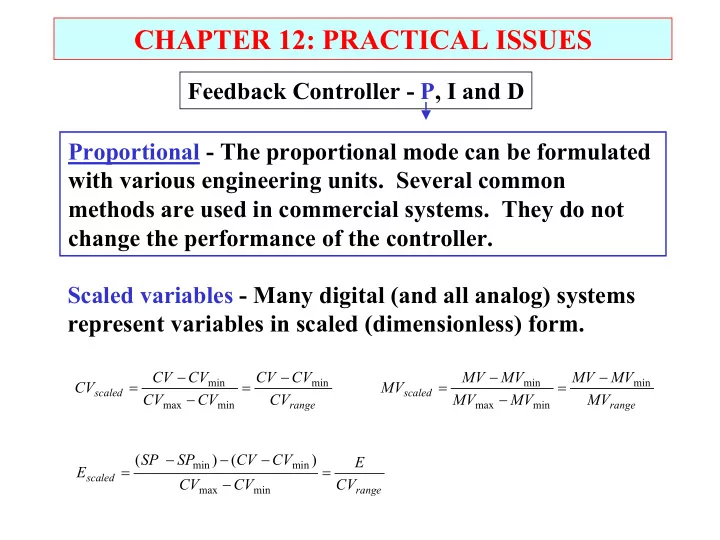

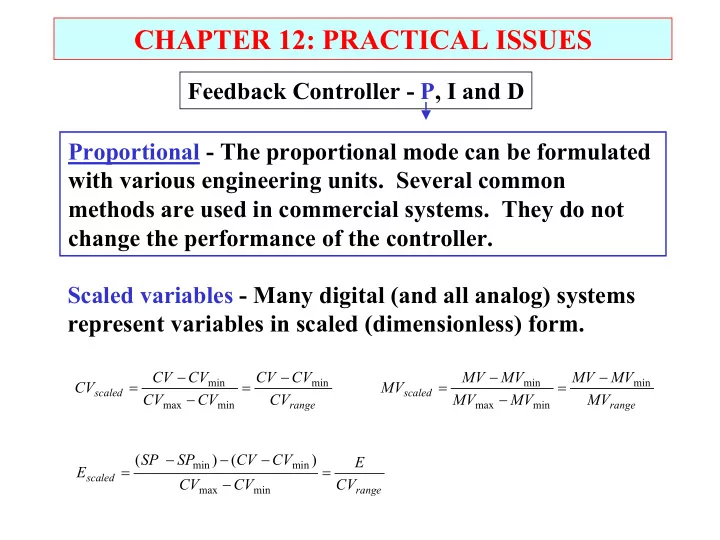

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D Proportional - The proportional mode can be formulated with various engineering units. Several common methods are used in commercial systems. They do not change the performance of the controller. Scaled variables - Many digital (and all analog) systems represent variables in scaled (dimensionless) form. − − − − CV CV CV CV MV MV MV MV = min = min = min = min CV MV scaled scaled − − CV CV CV MV MV MV max min range max min range − − − ( SP SP ) ( CV CV ) E min min = = E scaled − CV CV CV max min range

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D CV ( t ) d t MV ( t ) 100 E ( t ) 1 E ( t ' ) CV ∫ = + − + dt ' T r I d MV PB CV T CV dt r r I r 0 This is the Proportional Band. 100 = ( K ) In some software, the engineer c s PB must input PB.

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D t d CV ( t ) ∫ = + − + MV ( t ) K E ( t ) T E ( t ' ) dt ' T I c R d dt 0 This is the Reset Time. In some 1 = T software, the engineer must R T I input T R .

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D t d CV ( t ) ∫ = + − + MV ( t ) K E ( t ) T E ( t ' ) dt ' T I c R d dt 0 Reset Windup - The integral is persistent, it doesn’t stop until the error is zero. But, if the final element (valve) has reached its maximum or minimum, the integral should “stop”; if it doesn’t, the calculated value could increase in magnitude towards infinity. This is called reset windup and must be prevented.

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D Behavior without anti-reset-windup: The Behavior with anti-reset-windup: The controller output continues to change controller output stops at the boundary (winds up). It takes some time to return (doesn’t wind up). The increase in the to a value where the controller output controller output immediately affects the affects the valve. valve when needed Windup. The controller output No windup! exceeds the range of the valve movement.

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D Anti-reset-windup - Several approaches are used. One simple approach is demonstrated here. ∆ T ( t ) d ∆ = − + − − + MV K E E E ( CV 2 CV CV ) − − − N c N N 1 N N N 1 N 2 ∆ T t I = + ∆ MV MV MV − N N 1 N ≤ MV MV N max Anti-reset-windup modification ≥ MV MV N min MV is implemente d and stored for use as MV during the next iteration N N - 1

CHAPTER 12: PRACTICAL ISSUES Feedback Controller - P, I and D Derivative Filter - If we filter the measurement, we “slow” all controller modes. An option exists to filter only the derivative mode. α usually is specified as 0.1, which gives T s d a filter of 10% of the derivative time. α + T s 1 d

CHAPTER 12: PRACTICAL ISSUES Output processing Bumpless transfer - When the controller is switched from manual (off) to automatic (on), the final element (valve) should start from its initial value. = IF N 1 Special = MV Current output to final element N calculation for ∆ = MV 0 initialization N = − = E SP CV ; CV CV − N N N N 1 N ELSE = E E − N 1 N = − E SP CV N N N ∆ ( t ) T ∆ = − + − d − + MV K E E E ( CV 2 CV CV ) − − − N c N N 1 N N N 1 N 2 ∆ T t I END = + ∆ = = MV MV MV ; CV CV ; CV CV − − − − N N 1 N N 2 N 1 N 1 N ≤ MV MV N max ≥ MV MV N min

CHAPTER 14: CASCADE CONTROL When I complete this chapter, I want to be able to do the following. • Identify situations for which cascade is a good control enhancement • Design cascade control using the five design rules • Apply the tuning procedure to cascade control

CHAPTER 14: CASCADE CONTROL Outline of the lesson. • A process challenge - improve performance • Cascade design rules • Good features and application guidelines • Several process examples • Analogy to management principle

CHAPTER 14: CASCADE CONTROL F 1 L 1 feed T product 1 TC Discuss this PID controller 2 stirred tank heat exchanger. F 2 T 3 heating stream

CHAPTER 14: CASCADE CONTROL IAE = 147.9971 ISE = 285.4111 Class exercise: What do 76 TC we do? 75 F temperature 1 L 74 1 feed 73 minimum T 72 1 0 20 40 60 80 100 120 140 160 180 200 Disturbance = TC heating pressure 2 Control performance not acceptable! Pressure disturbance F 2 T 3 heating stream

CHAPTER 14: CASCADE CONTROL Let’s think about the F 1 L 1 feed process behavior. T product 1 • Causal relationship TC 2 from P disturbance to T (without control) P • What measurable F 2 T 3 effect always occurs heating stream when P changes? v (valve) → ??? → Q → TC P (heating oil)

CHAPTER 14: CASCADE CONTROL F 1 L 1 feed T product 1 TC Sketch a PID controller 2 Proposal here. F 2 T 3 heating stream

CHAPTER 14: CASCADE CONTROL A New Control Structure!! F 1 L 1 feed T product T2=CV 1 1 TC Key variables SP 1 from person primary 2 for the two PID controllers. SP 2 = MV 1 FC secondary 2 T v=MV 2 3 F2=CV 2 heating stream

CHAPTER 14: CASCADE CONTROL Control Performance Comparison for CST Heater Single-Loop Cascade IAE = 147.9971 ISE = 285.4111 IAE = 11.5025 ISE = 1.6655 76 76 75 75 temperature 74 74 73 73 72 72 0 20 40 60 80 100 120 140 160 180 200 0 50 100 150 200 Much better performance! WHY?

CHAPTER 14: CASCADE CONTROL Class exercise plant computer person computer T = − E T 2 T 2 T2 SP T 2 sp 2 t 1 ∫ = + + MV ( K ) E E dt ' I 1 c T 2 T 2 T 2 T 2 ( T ) I T 2 0 = F 2 MV SP 1 Each controller is a PID! F = − E F 2 F 2 F 2 sp 2 t 1 ∫ = + + MV ( K ) E E dt ' I 2 c F 2 F 2 F 2 F 2 ( T ) I F 2 0 = v MV 2

CHAPTER 14: CASCADE CONTROL F 1 L What have we gained 1 feed and lost using cascade T product 1 CV 1 control? TC SP 1 for person 2 For each case, is cascade better, same, SP 2 = MV 1 worse than single-loop FC 2 T feedback (TC2 → v)? 3 MV 2 CV 2 heating stream • A disturbance in heating medium inlet pressure • A disturbance in heating medium inlet temperature • A disturbance in feed flow rate • A change to the TC set point

CHAPTER 14: CASCADE CONTROL F 1 L What have we gained 1 feed and lost using cascade T product 1 CV 1 control? TC SP 1 for person 2 For each case, is cascade better, same, SP 2 = MV 1 worse than single-loop FC 2 T feedback (TC2 → v)? 3 MV 2 CV 2 heating stream • A disturbance in heating medium inlet pressure Cascade better • A disturbance in heating medium inlet temperature Both the same • A disturbance in feed flow rate Both the same • A change to the TC set point Both the same

CHAPTER 14: CASCADE CONTROL Very CASCADE DESIGN CRITERIA important Cascade is desired when 1. Single-loop performance unacceptable 2. A measured variable is available A secondary variable must 3. Indicate the occurrence of an important disturbance 4. Have a causal relationship from valve to secondary (cause → effect) 5. Have a faster response than the primary

CHAPTER 14: CASCADE CONTROL ADVANTAGES OF CASCADE CONTROL • Large improvement in performance when the secondary is much faster than primary • Simple technology with PID algorithms • Use of feedback at all levels. Primary has zero offset for “step-like” disturbances. • Plant operating personnel find cascades easy to operate. Open a cascade at one level, and all controllers above are inactive.

CHAPTER 14: CASCADE CONTROL A cascade is a hierarchy, with decisions transmitted from upper to lower levels. No communication flows up the hierarchy. • What are advantages of a hierarchy? • What information should be transmitted up the hierarchy? • What information should flow from secondary to primary in a cascade?

CHAPTER 14: CASCADE CONTROL Does cascade apply to instrumentation? Yes, a valve positioner is a secondary that reduces effects of friction!! F 1 L 1 feed T product 1 TC Valve positioner: 2 Measures the stem position and adjusts the air pressure to (closely) achieve the desired T position. This is located 3 at the valve. heating stream

Recommend

More recommend