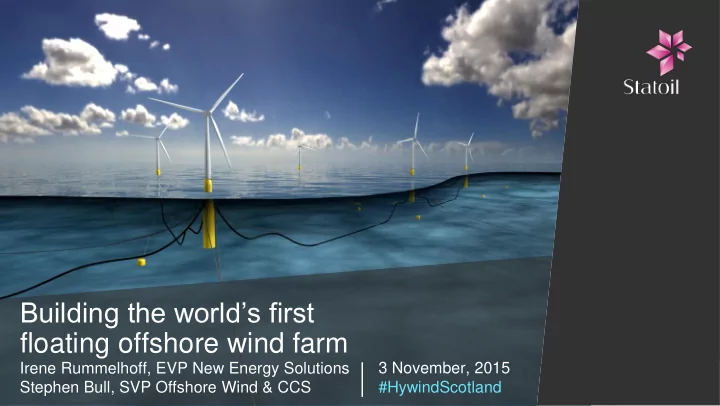

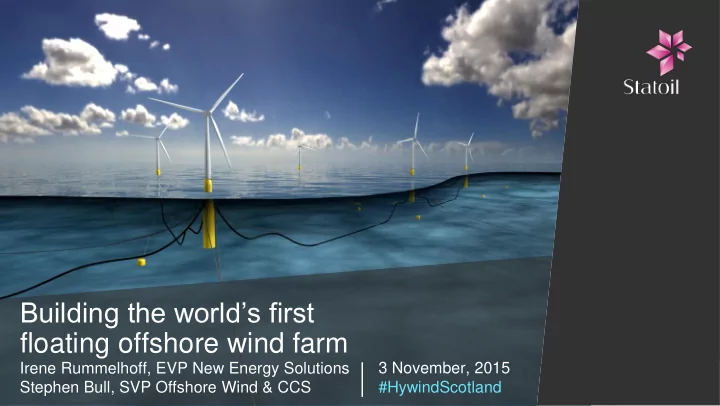

Building the world’s first floating offshore wind farm Irene Rummelhoff, EVP New Energy Solutions 3 November, 2015 Stephen Bull, SVP Offshore Wind & CCS #HywindScotland

First new investment for New Energy Solutions Development & New Energy Midstream & Portfolio Exploration Production management Solutions marketing • Leverage European • • • • Exploit prolific Safe and secure operations Realise value Build a distinct gas position basins growth portfolio of • • Drive cost and capital efficiency Sharpen our upstream profitable new, non- • Onshore access to • Test impact profile • Capitalise on technology and oil and gas options premium markets opportunities • operating experience Strengthen execution • Identify and develop • Exploit global trading • Access at scale and financial business models to competence resilience drive demand for our core products

Realising the Hywind Scotland pilot park • Average wave height : 1.8 m • Investing around NOK 2 billion • Installed capacity : 30 MW • Export cable length : Ca. 30 km • 60-70% cost reduction from the • Water depth : 95-120 m • Operational base : Peterhead • Avg. wind speed : 10.1 m/s Hywind Demo project in Norway • Start power production : 2017 • Powering ~20,000 UK homes • Area : ~4 km 2

Expanding the potential floating wind market Current projects Potential future markets Long-term potential prospects Illustrative only, based on water depths, wind conditions and potential large markets

Further developing the unique Hywind concept 2001- 2009- 2017- Pilot park: A world’s first Hywind: A bright idea Demo: Proven in the North Sea • Concept verified, performance • Development of larger and lighter • Unique concept beyond expectations units and economies of scale • Intellectual property owned by • Excellent production, well- • Further improving cost Statoil, patented technology functioning technical systems competitiveness

Applying proven technology in new application • Standard offshore wind turbine • Spar-type substructure • Simple structure - efficient fabrication • Suitable for harsh conditions • Simple 3-line mooring system • Patented motion control reduces fatigue, increases production

Enabling utility-scale floating wind production

Bringing down the cost LCOE (NB: Illustrative) Cost reduction of 40-50% by 2030 realistic, making floating offshore wind competitive without support regimes Target Base Opera- Yield Sub- Supply Infra- Instal- WTG Target case tions structure chain structure lation 2020 2030

Recommend

More recommend