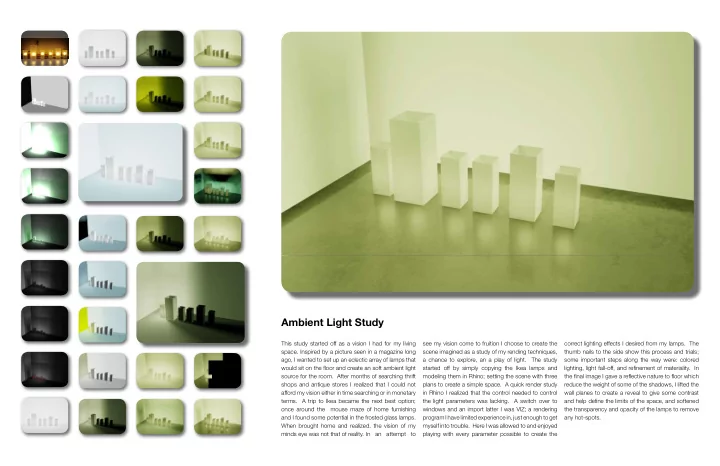

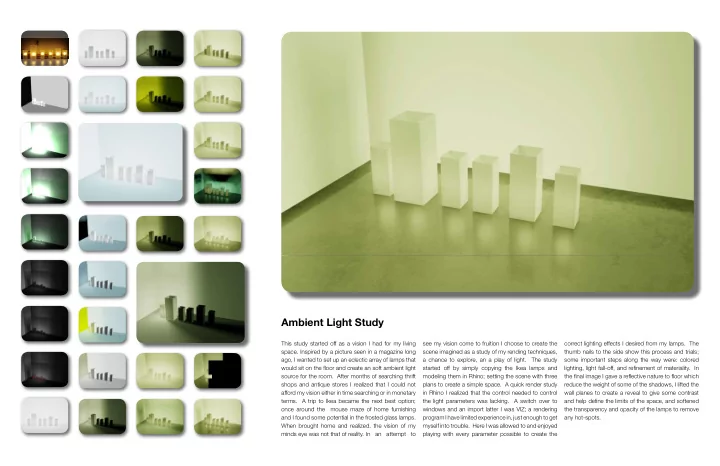

Ambient Light Study This study started off as a vision I had for my living see my vision come to fruition I choose to create the correct lighting effects I desired from my lamps. The space. Inspired by a picture seen in a magazine long scene imagined as a study of my rending techniques, thumb nails to the side show this process and trials; ago, I wanted to set up an eclectic array of lamps that a chance to explore, an a play of light. The study some important steps along the way were: colored would sit on the fm oor and create an soft ambient light started off by simply copying the Ikea lamps and lighting, light fall-off, and refi nement of materiality. In source for the room. After months of searching thrift modeling them in Rhino; setting the scene with three the fi nal image I gave a refm ective nature to fm oor which shops and antique stores I realized that I could not plans to create a simple space. A quick render study reduce the weight of some of the shadows, I lifted the afford my vision either in time searching or in monetary in Rhino I realized that the control needed to control wall planes to create a reveal to give some contrast terms. A trip to Ikea became the next best option; the light parameters was lacking. A switch over to and help defi ne the limits of the space, and softened once around the mouse maze of home furnishing windows and an import latter I was VIZ; a rendering the transparency and opacity of the lamps to remove and I found some potential in the frosted glass lamps. program I have limited experience in, just enough to get any hot-spots. When brought home and realized, the vision of my myself into trouble. Here I was allowed to and enjoyed minds eye was not that of reality. In an attempt to playing with every parameter possible to create the

-Dynamic Shape | Simple Form -Layering -Refmective Light

- Dynamic Shape | Simple Form -Layering - Refmective Light

- Dynamic Shape | Simple Form - Layering -Refmective Light

-Dynamic Shape | Simple Form - Layering - Refmective Light

-Dynamic Shape | Simple Form -Layering - Refmective Ambient Light

-Dynamic Shape | Simple Form -Layering -Refmective Ambient Light

Futuropolis | Daniel Libeskind The Futuropolis project was project designed by Daniel Libe- out of birch wood; using 200 hours of CNC milling time as well skind as exhibition sculpture for the freshman orientation week as 500 man-hours for assembly. wood sculpture | 2005 at HSG, a renowned business school in St. Gallen Switzerland. The towers that were created were to help the incoming busi- In order to reduce production time an algorithmic formula was ness students visualize and conceptualize a “City of the Fu- created in VectorWorks, VectorScript, by a group of students at ture.” The wooden sculpture is a composition of 98 towers ETH under the direction of CAAD Chair Prof. Dr. Ludger Hove- Client_ Universtiy of St. Gallen (HSG) arranged on a triangular grid ranging in height up to 3.8meters stadt. By using the parametric functions of the program they Design_ Studio Daniel Libeskind, Libeskind and T. Garbers (12.5 ft). The triangular grid pattern of the base was applied to were able to generate the geometry of the 2,164 parts as well Consulting and Engineering_ designtoproduction, ETH the vertical form at an angle of 25 degrees. This cut the form as accommodating late-stage design alterations made by Libe- CNC-Production_ Bach Heiden AG into approximately 2000 polygons that would be constructed skind. The team generated a stencil that could be manually

edited but automatically alter and create the assembly pieces. the project; first they developed the connection method of the mm boards. The final G-code was then outputted, overnight, By using the system along with the cooperation and partner- board, secondly they generate the exact geometry of the parts, into two separate scripts since the boards had to be turned ship of designtoproduciton the cost of the time for the project and finally translated the geometry information in code for the around in the middle of the production process. was cut down to two weeks and a savings of 320,000 Swiss CNC-milling process (G-Code). The design of the connectors Francs (300,000 US). was found to be six variants, of aluminum dovetail connectors, Bach Heiden AG was the producer of finished materials and with eleven sub-types; the notices for the aluminum connec- construction. They specialize in high-tech machinery as well Designtoproduction is a consulting service that facilitates para- tors could be milled out by the CNC-router. The geometry of as wood and solid skills. By using the most current machin- metric planning, detailing, optimization, and digital manufactur- the 2,164 parts was created by taking the parametric model for ery, e.g. 5-axis CNC, they are able to do small-scale fabrication ing for the production of non-standard architecture. In the case the research done at ETH integrated with the connection details at similar price points to large scale ones. Bach Heiden has of the Futuropolis project they performed three vital steps to and then numbered and applied to 360 square meters of the 32 worked with designtoproduction on other project such as the

ization of the object. What this process allows for is mass cus- Inventioneering Architecture exhibit, Swissbau Pavillion, and the tomization; allowing small-scale projects, like Futuropolis, to be Zipshape chair. quickly produced and constructed on small budgets. At the end of the process what was truly created was a digital Works Cited mic Architecture. Barcelona: Actar, 2007. Print. design chain. A design chain is a design and production se- Hovestadt, Ludger. Chair of Computer Aided Architectural Design 1st-4th Year. Scheurer, Fabian, Christoph Schindler, and Markus Braach. From Design To Production: Three Hovestadt.pdf. ETH Zurich: D-Arch. Web. 2 Mar. 2010. <http://www.arch.ethz.ch/jahrbuch06/hove- Complex Structures Materialised In Wood. From Design To Production. Generative Art. Web. 2 Mar. quence with no analogue steps; an uninterrupted digital process stadt.pdf>. 2010. <http://www.generativeart.com/on/cic/papers2005/36.ScheurerSchindlerBraach_final. htm>. form design (determination of shape and structure) to construc- Johnson, David, ed. “VectorWorks Plays Key Role IN Designing Swiss ‘Inventioneering Architecture’ Exhibit.” Live Design (11 Jan. 2006). Live Design. Penton Media, INC, 11 Jan. 2006. Web. 25 Feb. Schindler, Christoph. “TWiki.D2p.LibeskindFuturopolis.” TWiki.D2p.LibeskindFuturopolis. Web- 2010. <http://livedesignonline.com/architainment/inventioneering_architecture/>. Home, 20 Aug. 2006. Web. 25 Feb. 2010. <http://wiki.arch.ethz.ch/twiki/bin/view/D2p/Libe- tion (detailing) to production (CNC-manufacturing). This chain skindFuturopolis.html>. “Libeskind’s Futuropolis: St. Gallen, 2005.” Designtoproduction. Designtoproduction. Web. 25 Feb. integrates the need for dynamic and malleable programs that 2010. <http://www.designtoproduction.ch/content/view/12/41/>. VectorWorks. Case Study. VectorScript and Parametric Modeling Technolgy Bring Daniel Libe- skind’s Futuropolis to Life. News: Case Study. Nemetschek.net. Web. 25 Feb. 2010. <http://www. can be simply modified, but then very quickly moved to a real- Sakamoto, Tomoko (ed. )., and Albert (ed. ). Ferré. From Control to Design: Parametric/Algorith- nemetschek.net/news/casestudies.php>.

Recommend

More recommend