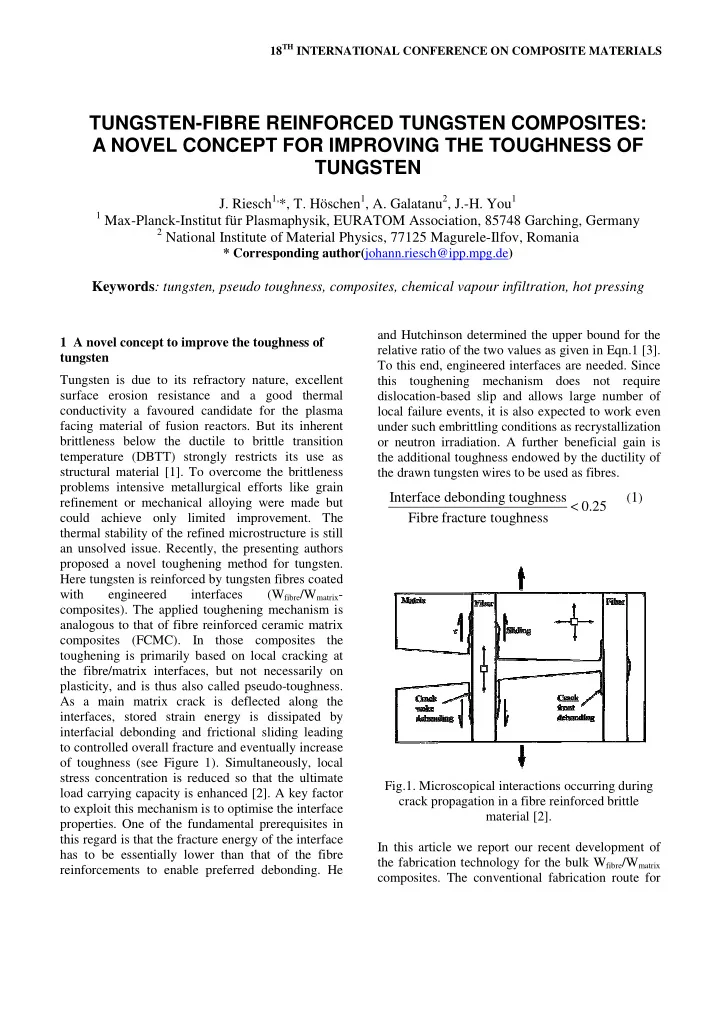

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS TUNGSTEN-FIBRE REINFORCED TUNGSTEN COMPOSITES: A NOVEL CONCEPT FOR IMPROVING THE TOUGHNESS OF TUNGSTEN J. Riesch 1, *, T. Höschen 1 , A. Galatanu 2 , J.-H. You 1 1 Max-Planck-Institut für Plasmaphysik, EURATOM Association, 85748 Garching, Germany 2 National Institute of Material Physics, 77125 Magurele-Ilfov, Romania * Corresponding author( johann.riesch@ipp.mpg.de ) Keywords : tungsten, pseudo toughness, composites, chemical vapour infiltration, hot pressing and Hutchinson determined the upper bound for the 1 A novel concept to improve the toughness of relative ratio of the two values as given in Eqn.1 [3]. tungsten To this end, engineered interfaces are needed. Since Tungsten is due to its refractory nature, excellent this toughening mechanism does not require surface erosion resistance and a good thermal dislocation-based slip and allows large number of conductivity a favoured candidate for the plasma local failure events, it is also expected to work even facing material of fusion reactors. But its inherent under such embrittling conditions as recrystallization brittleness below the ductile to brittle transition or neutron irradiation. A further beneficial gain is temperature (DBTT) strongly restricts its use as the additional toughness endowed by the ductility of structural material [1]. To overcome the brittleness the drawn tungsten wires to be used as fibres. problems intensive metallurgical efforts like grain Interface debonding toughness ( 1 ) < refinement or mechanical alloying were made but 0 . 25 could achieve only limited improvement. The Fibre fracture toughness thermal stability of the refined microstructure is still an unsolved issue. Recently, the presenting authors proposed a novel toughening method for tungsten. Here tungsten is reinforced by tungsten fibres coated with engineered interfaces (W fibre /W matrix - composites). The applied toughening mechanism is analogous to that of fibre reinforced ceramic matrix composites (FCMC). In those composites the toughening is primarily based on local cracking at the fibre/matrix interfaces, but not necessarily on plasticity, and is thus also called pseudo-toughness. As a main matrix crack is deflected along the interfaces, stored strain energy is dissipated by interfacial debonding and frictional sliding leading to controlled overall fracture and eventually increase of toughness (see Figure 1). Simultaneously, local stress concentration is reduced so that the ultimate Fig.1. Microscopical interactions occurring during load carrying capacity is enhanced [2]. A key factor crack propagation in a fibre reinforced brittle to exploit this mechanism is to optimise the interface material [2]. properties. One of the fundamental prerequisites in this regard is that the fracture energy of the interface In this article we report our recent development of has to be essentially lower than that of the fibre the fabrication technology for the bulk W fibre /W matrix reinforcements to enable preferred debonding. He composites. The conventional fabrication route for

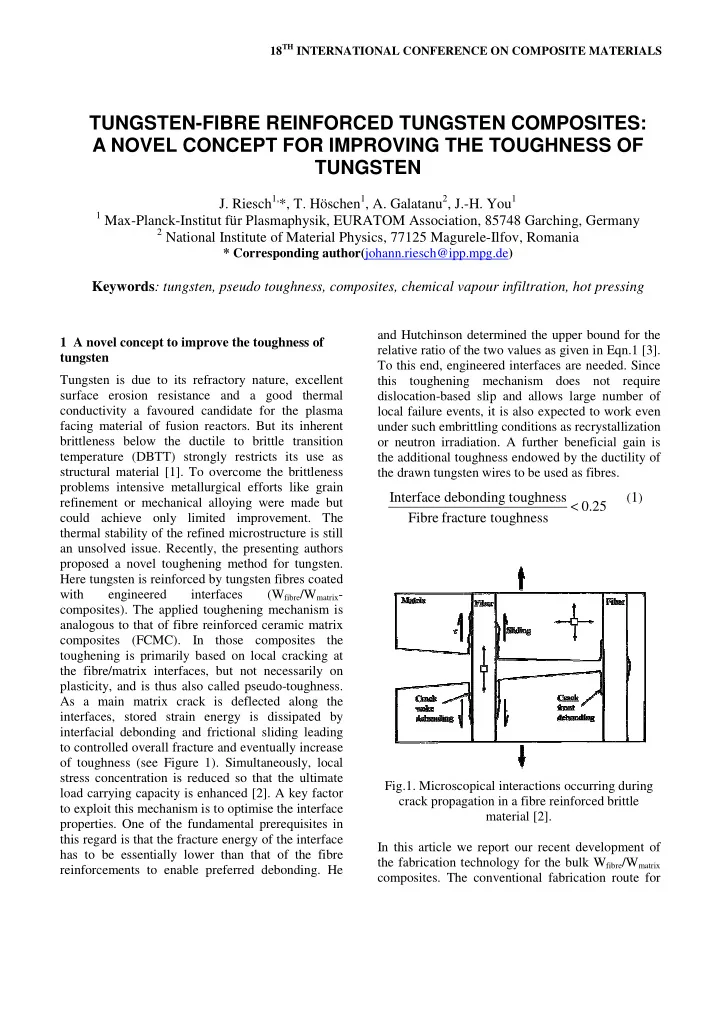

tungsten-base materials is powder metallurgy [4] reinforcements embedded in a rather dense tungsten (due to the refractory nature of tungsten). However, matrix with preserved interfacial films as illustrated a powder metallurgical processing route requires schematically in Figure 2. Commercial product of very high temperatures and pressures for the drawn wire with a diameter of 150 µm was used as consolidation process and would therefore impose fibre. serious impacts on the properties of W f /W m - At first the wires were arranged in a regular pattern composites. The engineered interfaces and also the to form a uni-directional fibre preform. The preform fibre alignment in the composite would be possibly should provide an accurate positioning of the fibres destroyed. Extensive research effort is necessary to in equal distances with each other but also allow free evaluate the applicability of powder metallurgy for access to all fibres at the same time. The distance the fabrication of W f /W m composites. was chosen to be 100 µm which led to final fibre volume fraction of about 30 %. The unidirectional An alternative processing route for tungsten without configuration of the fibres was supposed to simplify severe thermo-mechanical impact which is widely the interpretation of experimental results as well as used for the fabrication of coatings is chemical the production itself. To achieve the well defined vapour deposition (CVD). This technique was fibre architecture we used a commercial winding already successfully applied to the single-fibre device actually to be used for electro-magnetic coils. W f /W m -mini-composites by the author’s group [5]. The tungsten wire was wound around a frame The single-fibre composites consisted of a tungsten equipped with spacer foils to form a preform which filament (diameter: 150 µm) coated with a thin film required considerable manual efforts. An example of (thickness: 1 µm) to form a well-defined interface a final preform is shown in Figure 3. layer using magnetron sputtering (PVD) embedded Matrix: into a thick mantle of dense tungsten (1-1.5 mm) W-CVI produced by CVD. This CVD-based fabrication of the single-filament composites was not difficult and could produce large number of specimens with different interface coatings in a single batch. However, CVD method could not be applied to a Interface: WO x multi-filament composite system due to the low Fibre: quality of matrix filling. Drawn W-wire A variant of CVD is the chemical vapour infiltration Fig.2 Architecture of a W fibre /W matrix -composite (CVI) technique. Here the conventional CVD sample: Continuous tungsten wires are embedded process is combined with an additional infiltration step to fill porous or fibrous preforms. Currently the into a dense tungsten matrix (produced by W-CVI) with coated interfaces. CVI technique is widely used for the fabrication of fibre-reinforced ceramic composites (e.g. C/C, SiC/SiC, SiC/Si 3 N 4 ) [6]. The main advantages of The interface coating can be made either before or after the preform winding process. In the latter case, CVI are relatively low processing temperatures and the whole fibre bundle has to be coated at once. The minimal mechanical impact. In this work we applied the CVI process on tungsten (W-CVI) to fabricate advantage of a single wire coating process is that the technique is straightforward to use and flexible in multi-filament bulk composites of W f /W m system. terms of quality management. But the thin surface Dedicated equipment was used to achieve a reasonably high matrix filling quality by means of a coatings have to withstand the mechanical damage to be caused during the preform preparation. In this controlled temperature gradient. work, we made wire coating on the preform after winding. Tungsten oxide film was deposited by 2 Synthesis of W f /W m -composites by the direct oxidation of the surface. The formed oxide chemical vapour infiltration of tungsten (W-CVI) film was not stoichiometric (WO x ) and expected to We designed the multi-fibre W f /W m -composites in have a sufficiently low toughness to fulfil the crack such a way as to consist of hundreds of aligned fibre deflection criterion. For comparison bare wires

Recommend

More recommend