18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS THE EFFECT OF FIBRE CHEMICAL TREATMENTS ON HEMP REINFORCED COMPOSITES H. Wang*, M.M. Kabir, K.T. Lau Centre of Excellence in Engineered Fibre Composites, Faculty of Engineering & Surveying, University of Southern Queensland, Toowoomba, Australia * Corresponding author (wangh@usq.edu.au) Keywords : Hemp fibre, natural fibre composites, chemical treatments 1 Introduction prepared using vacuum assisted resin infusion. Glass or carbon fibres are traditionally used as Hemp fiber volume fraction was kept at about40%. reinforcement in engineering composites. The The chemical analysis was used to determine the increasing ecological and environmental concerns percentage of cellulose, hemicellulose and lignin in have led to the use of natural fibres as renewable the fibre before and after treatments. FTIR, DSC and alternatives [1]. Among them, hemp fibre offers the SEM were used to characterize the fibres. best mechanical properties as well as abundant The flexural test was performed by using a computer availability. However, the hemp fibre, same as other controlled universal testing machine of 10kN load natural fibres, has the issues of fiber/matrix bonding cell. The ASTM D-790 test method was followed and moisture absorption [2]. Hydrophilic nature of and a span to depth ratio of 16:1 was maintained. hemp fibre causes a weak bonding with hydrophobic The cross-head speed of 2mm/min was applied. The polymers matrix and the property deterioration shear properties of the samples were measured during service [3]. accordance to ASTM D-5379 standard. At least five Chemical treatments are needed to modify the specimens of each sample were used and reported surface of fibre, aiming at improving the adhesion the average values. with polymer matrix and reducing the hydrophilicity Mechanical properties of the composites were tested of the fibre. Alkalization, acetylation and the using three point bending and shear tests. combination were used in this study to treat the 3 Results and Discussion hemp fibre. The effects of the chemical treatments on the fibre and the hemp fibre reinforced 3.1 Chemical Constituents of Fibres composites were investigated. Natural fibres are complex in structure. They are generally lignocellulosic, consisting of helically wound cellulose microfibrils in an amorphous 2 Materials and Experimental matrix of lignin and hemicelluloses [4]. Mechanical Hemp fibres were obtained from Eco Fibre properties of fibre are dominated by the cellulose Industries. The fibres were first washed and dried. content and microfibril angle. A high cellulose For alkalization treatment, the fibres were soaked in content and low microfibril angel are desirable 6% NaOH at room temperature for 3 hours. For properties in a fibre to be used as reinforcement in acetylation treatments, the fibres were soaked in composites [5-7]. acetic acid first then immersed into acetic anhydride at room temperature for 3 hours. For the combined Table 1. Chemical constituents of untreated and treatment, the fibres were treated with 6% NaOH, NaOH treated hemp fibres . followed by acetylation treatment. After the Fibres Cellulose Hemi- Lignin chemical treatment, the fibres were washed with distilled water and dried in an 80ºC for 24 hours. (%) cellulose (%) Unsaturated polyester was used to make the hemp untreated 80.5 6.2 7.3 reinforced composites. Methyl ethyl keton peroxide 6% NaOH 84.1 4.9 5.0 was used as curing catalyst. The composites were 10% NaOH 94.2 5.0 3.5

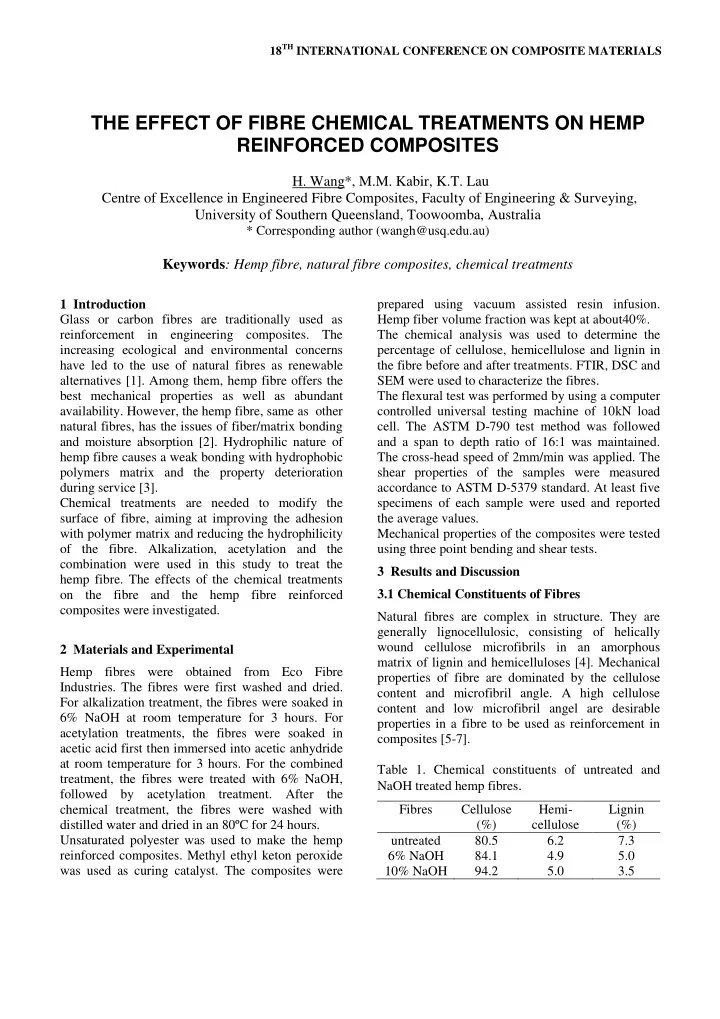

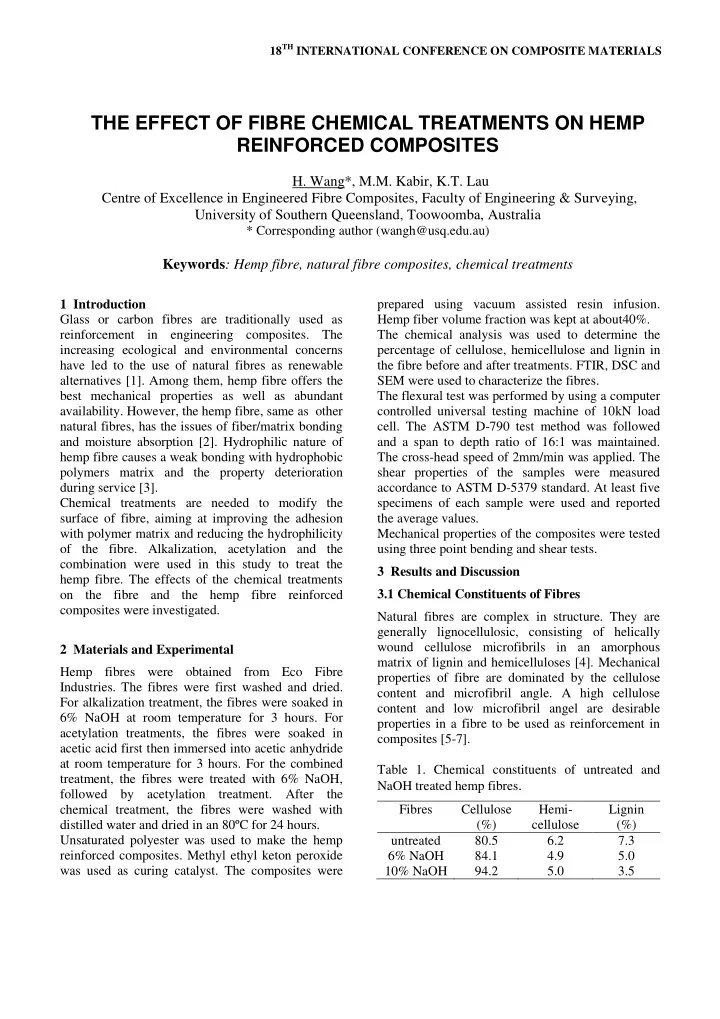

The band 1737cm -1 is correspondent to the C=O NaOH and other chemical treatments can remove the impurity of hemp fibre, clean its surface and degrade stretching in the actyl groups of hemicelluloses of lignin. It effectively increases the fibre’s cellulose the untreated fibres [11]. This band disappears for content and provides much cleaner and smoother the alkali treated samples. This indicates that surface for polymer matrix adhesion [1, 5, 7-8]. hemicelluloses were removed from the fibre surface. Table 1 shows the chemical constituents of hemp For the acetylated fibre, this band is shifted to 1726cm -1 . fibres before and after NaON treatment. The band at 1249cm -1 for untreated fibre is 3.2 FTIR Analysis corresponded to the C=O stretching in the aromatic ring of lignin [11]. For alkali and acetylation treated The FTIR spectra of untreated, alkali, acetylation fibres this band was up-shifted to 1256cm -1 and and alkali+acetylation treated fibres are given in Fig. 1253cm -1 respectively. From these results, it proves 1 and Table 2. The broad band at 3407 cm -1 is the that lignin attached on the surface of fibre was characteristic band for -O-H stretching for untreated removed by the designated chemical treatments. fibres [9-10]. Chemical treatments such as alkali and In summary, the FTIR analysis confirms the acetylation shifted the band to 3434cm -1 and chemical constituents results, which is that alkali 3419cm -1 respectively, and increased it intensity. and acetylation treatments remove the hemicellulose This is the indication of the reduction of hydrogen and lignin from the fibre. As a result, it effectively bonding in cellulosic hydroxyl groups, thereby increases the cellulose content in the fibre, more increasing -OH concentration. As a result the importantly, it exposes more reactive -OH group in hydrophilic nature of the fibre is decreased and more cellulose to react with the matrix, therefore increase reactive -OH group is exposed to react with the the bonding between fibre and matrix. matrix. 3.3 DSC Analysis of Fibres Table 2. Infrared transmittance peaks (cm -1 ) of DSC analysis enables to identify the chemical untreated and treated fibres activity occurring in the fibre as heat was applied Fibre O-H C=O C=O C=O [12-13]. Fig. 2 shows the thermal response of the stretching stretching stretching stretching untreated and chemical treated hemp fibres as a (cellulose) (hemi-c) (hemi-c) (lignin) function of temperature. Both untreated and treated Untreated 3407 1737 1643 1249 fibres exhibited one broad endothermic peak Alkali 3434 - 1650 1256 between the temperature of 70-90°C and one Acetylati 3419 1726 1643 1253 exothermic peak between 260-380°C. The first endothermic peak corresponds to the evaporation of moisture absorbed by the fibre. In this region some variations of thermal energy were observed with the effect of alkali and acetylation treatment compared Un to the untreated fibre. This was due to the changes of fibre moisture absortion after treatment [1]. Heat 6%Na flow rate for moisture evaporation on untreated fibre Absorbance is observed less than the treated fibres. This is Ac because less moisture was absorbed by the treated 6%Na+Ac fibres, therefore it requires higher energy to evaporate. The exothermic peaks in Fig. 2 correspond to the decomposition of cellulose, hemicelluloses and lignin of the fibres. In natural fibres, lignin degrades 4000 3500 3000 2500 2000 1500 1000 500 at the temperature around 200°C while the other Frequency (cm-1) constituents such as hemicelluloses and cellulose Fig. 1. FTIR spectra of the fibres. degrades at higher temperatures [14]. For untreated 2

fibre, the exothermic peaks were observed at On the other hand, the acetylated fibre shows a bit temperatures of 260-370°C, while all treated fibres rougher and brittle surface as compared with other showed exothermic peak at higher temperatures, fibres. Several transverse cracks appear on the fibre between 300-385°C. This was presumably due to the surface. This may be due to the reaction between acetyl groups with the fibre’s hydroxyl groups and partial removal of lignin and hemicelluloses from the fibres by alkali and acetylation treatment. As a thus the molecular orientation of the cellulose result, thermal stability of the treated fibres was backbone changed. As a result, the fibre becomes increased as compared with the untreated fibre. In rougher and stiffer in character [9]. This reduces the addition to this, hydrophobicity of the treated fibre hydrophilicity of the fibre and provides better was increased as the tendency of water molecules bonding with the matrix materials. held by the lignin and hemicelluloses were reduced. 3.4 SEM Analysis of Fibres Fig. 3 shows SEM micrographs of the surface of hemp fibres before and after treatments. The SEM image of the untreated hemp fibres shows some impurity substance on the surface. Chemical treatment certainly removed most of the impurity. The surface is clean. The alkali treated fibre demonstrates more rough surface as compared with the untreated fibre. Several chemical groups (in a pattern of partition) are formed on the surface of the Untreated fibre, which hold the fibrils together to form tightly packed fibre bundle. This pattern can also enhance the friction between the fibre and matrix, which makes the fibre pull out more difficult. The formation of the rough surface in the alkali treated fibre is due to the removal of hemicelluloses and lignin constituents by alkali treatment, which results in more reactive hydroxyl group exposed on the fibre surface [12-13]. The surface roughness facilitates better interfacial adhesion with the matrix and thus to get higher mechanical properties of their resultant composites. NaOH treated 5 Un 0 Heat flow (W/g) -5 6%Na+Ac -10 Ac -15 6%Na -20 -25 0 100 200 300 400 Acetylation treated Temperature ( C) Fig. 3. SEM micrograph of the untreated and Fig. 2. DSC analysis of untreated, alkali, acetalytion treated hemp fibres. and alkali+acetylation treated hemp fibres. 3

Recommend

More recommend