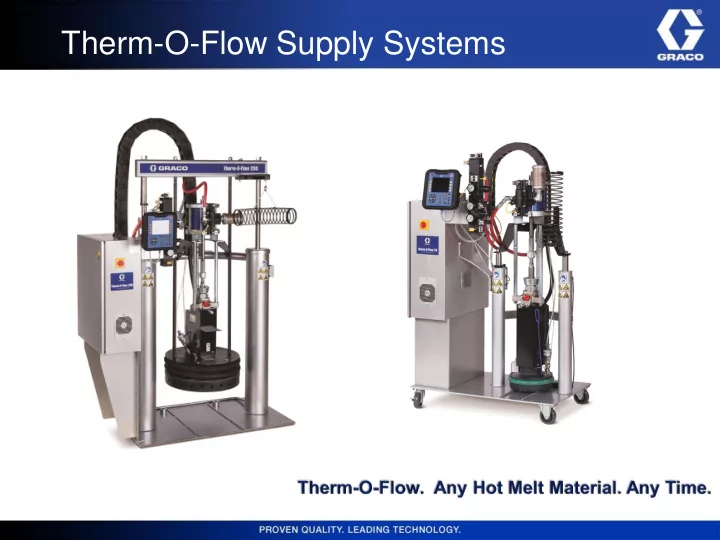

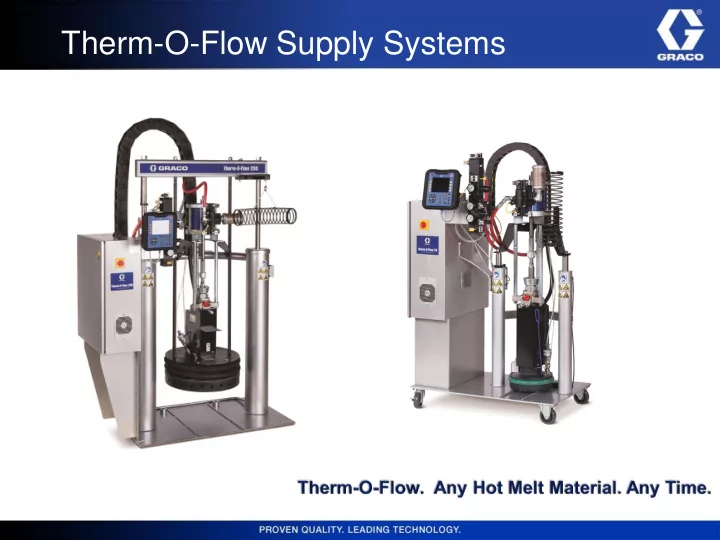

Therm-O-Flow Supply Systems

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories Improve Process Efficiency – Automatic electric crossover eliminates downtime with tandem units – keep your production running while drums/pails are being changed. – Sensors signal when drums are getting low or empty, and more material is needed. – Pump throat seals and plate seals are the only wear components on Therm-O-Flow and can be changed in less than one hour. – New packing and pump rod designs extend the maintenance cycle at least seven times. – Heated platens have cast-in heaters which never need to be replaced – and carry a lifetime warranty. – Material totalizers simplify preventative maintenance scheduling. Improve Production Capacity – Patented Mega- Flow™ platen offers greater throughput while reducing material waste compared to a standard finned platen. – Eliminates need for lengthy oven melting of solid or high viscosity resins – melts resins on demand, only what you need. – Automatic daily startup without delay – Therm-O-Flow is ready when the shift starts – User downloadable operating data to monitor and control your process, reducing unplanned downtime and increasing process efficiency. Reduce Energy Costs – Throughput capability 200% greater than the leading competitor. – Inactivity shutoff saves energy costs, promotes safety and prevents material charring. Support Environmental Initiatives – Built-in runaway control automatically shuts down supply system in event of component failure or empty drum. – The quiet, low noise NXT Air Motor operates around 87 decibels, while other comparable motors operate up to 103 decibels.

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories What’s New? Upgrade to Graco Control Architecture – Improved reliability – Data tracking, USB downloads of adhesive consumption – Not compatible with old systems 6, 10 and 14 Zone Configurations – 4, 8 and 12 external zones – Field upgradeable No More Basic/Advanced Models – Level sensors have been made standard – Discrete I/O included – Light tower optional – No Ethernet interface (yet…)

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories What’s New? New Throat Packing • New design has 7-12x longer life with PUR type adhesives! • Improved tolerances, finishes • Extended pump rod • Kits available for retrofit Merkur Air Motor Technology • New model. • More efficient. • Less cost. Hoses & Accessories • No changes • Ability to leverage existing

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories Materials – Butyl Rubber – Polyurethane Reactive (PUR) – Pressure Sensitive Adhesives (PSA) – Polyisobutylene (PIB) – Prepreg Resin Mixes – Epoxies – Warm Melt Sealers Product Assembly Transportation Construction – – – Appliances: Bonding Headliners: Bonding Window: Insulated Glass, Backbedding – – Furniture: Laminating, Bonding Headlights, Taillights: Bonding – Door: Laminating, Bonding – – Kitchen Cabinets: Laminating, Bonding Seating: Bonding – Manufactured Housing: Floors, – – Tape and Label Coating RV Flat Panel: Laminating, Walls, Roofing, Cabinets Bonding – Solar Panel Sealing – Cable Manufacturing – Filters

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories NXT Air Motor Model TF15 (15:1) 200 TF23 (23:1) 20 TF36 (36:1) Tandem Primary TF70 (70:1) Tandem Secondary Pump Packings Standard-Duty PTFE Heat Zones Heavy-Duty Carbon 6 Zones Fiber 10 Zones 14 Zones Platen Wipers T-Wiper Power Supply Black EPDM 220 VAC Black Chlorobutyl 380/400 VAC Green Silicone 480 VAC 575 VAC Heated Platen Ram Power Smooth Pneumatic Finned Hydraulic Mega-Flo Therm-O-Flow 200 shown above

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories TOF 200 • Platen Options – Mega-Flo (11 lbs./min.) – Finned (4 lbs./min.) – Smooth (1.5 lbs./min.) Mega-Flo • Platen Seal Options Option Placement Material Construction Max. Operating Temp. Recommended Use Option 1 Upper Black EPDM Hose Wiper, SS Wire Braid, Spring Retention 400F (204C) Butyl Rubber and like Lower Black EPDM Hose Wiper, SS Wire Braid, Spring Retention 400F (204C) materials Option 2 Upper Green Silicone Hose Wiper, Fiberglass Braid 350F (177C) Butyl Rubber and like Lower Black EPDM, SS Wire Braid, Spring Retention 400F (204C0 materials Option 3 Upper White Silicone T-Wiper 250F (121C) PUR, PSA, EVA and like Lower White Silicone T-Wiper 250F (121C) materials Option 4 Upper White Silicone T-Wiper 250F (121C) PUR, PSA, EVA and like Lower Black EPDM Hose Wiper, SS Wire Braid, Spring Retention 400F (204C) materials

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories TOF 20 • Platen Options – Finned – Smooth • Drum Seal Options – Silicone coated round wiper – 400F

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories TOF 200 • All rams are based off the 6.5” ram but are available in either – Pneumatic – Hydraulic TOF 20 • All rams are based off the 3” ram and are only available in pneumatic

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories • TOF 200 Pump Options – Checkmate 200 is the only pump lower • Available with PFTE (normal duty) or Carbon Fiber (abrasive materials) packings – 3 Air motor options - Air Motor and Power Viscosity @ Fluid Ratio Temperature Flow Rate Pressure TF23 (23:1) Low to medium Up to 11 lbs Up to 2,300 psi (up to 50,000 cps) (5.0 kg) per minute (159 bar) TF36 (36:1) Low to medium Up to 11 lbs Up to 3,000 psi (up to 300,000 cps) (5.0 kg) per minute (210 bar) TF70 (70:1) Medium to high Up to 11 lbs Up to 3,000 psi (up to 2,000,000 cps) (5.0 kg) per minute (210 bar)

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories User Interface – GCA, ADM Platform – Simple, Easy to Use – Intuitive – USB Download of Operating Data – Material consuption – Operating temperatures – Errors and Events • Control Features – Pump Runaway Control – 7-day Timer – Adjustable Set Back – Integrated Self-diagnostics

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories Air Controls – Control Panel Air Regulators • Integrated Drum Air Blow-Off • Air Motor • Ram Up • Ram Down – Integrated Drum Air Blow-Off • Convenient, Easy Drum Changing

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories Tandem Systems • Provides uninterrupted production • When one drum is empty, simply switch over to system with full drum • Replace empty drum for future use

Graco Online Training – TOF Supply Systems • • System Overview Pump Selection • • System Identification Electronics • • Platen/Wiper Selection Tandem Systems • • Ram Selection Accessories • Applicators – Manual Extrude / Swirl – Automatic Extrude / Swirl • Crossover Tandem Option – Increased versatility – Uninterrupted production Hot Melt, High Pressure Manual Applicator • Accessory Box Hot Melt, High Pressure – Additional 4 Heat Zones Automatic Applicator – Installed independent of TOF system • Flow control – Closed Loop Auto-Control with PCF – Heated Mastic Regulator, Compensator • Heated Hoses – Range of lengths and diameters Heated Mastic Heated Hose Regulator

Recommend

More recommend