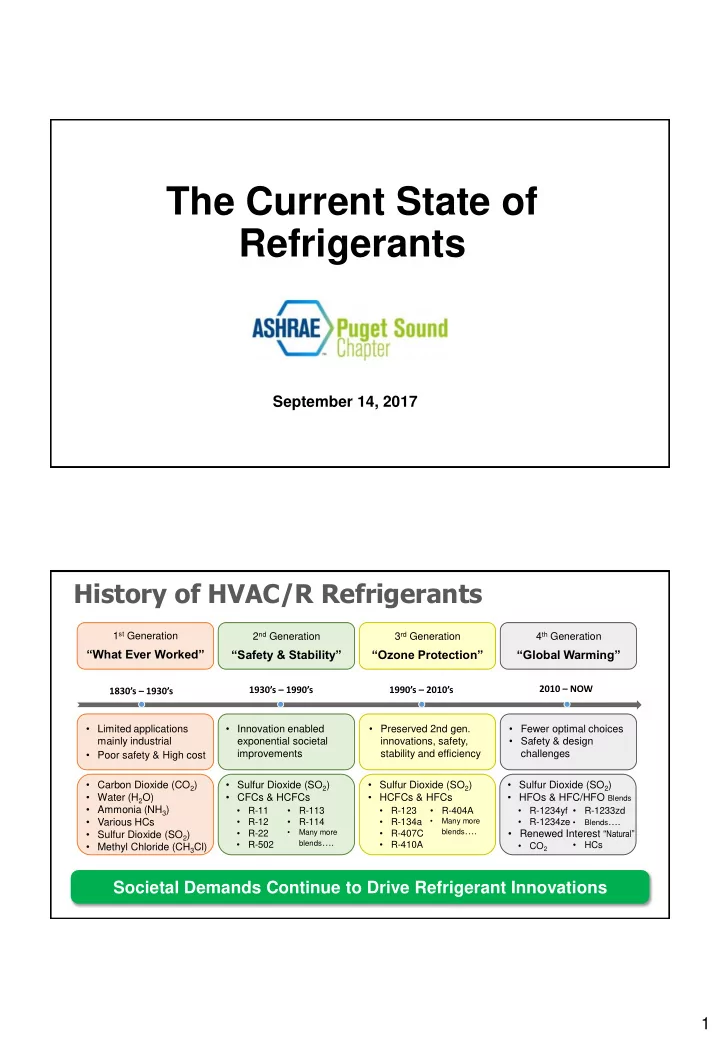

The Current State of Refrigerants September 14, 2017 History of HVAC/R Refrigerants 1 st Generation 2 nd Generation 3 rd Generation 4 th Generation “What Ever Worked” “Safety & Stability” “Ozone Protection” “Global Warming” 1930’s – 1990’s 2010 – NOW 1990’s – 2010’s 1830’s – 1930’s • Limited applications • Innovation enabled • Preserved 2nd gen. • Fewer optimal choices • Safety & design mainly industrial exponential societal innovations, safety, • Poor safety & High cost improvements stability and efficiency challenges • Carbon Dioxide (CO 2 ) • Sulfur Dioxide (SO 2 ) • Sulfur Dioxide (SO 2 ) • Sulfur Dioxide (SO 2 ) • Water (H 2 O) • CFCs & HCFCs • HCFCs & HFCs • HFOs & HFC/HFO Blends • Ammonia (NH 3 ) • • • • • • R-11 R-113 R-123 R-404A R-1234yf R-1233zd • Various HCs • • • • • Blends …. Many more R-12 R-114 R-134a R-1234ze • blends …. • • • • Renewed Interest “ Natural ” • Sulfur Dioxide (SO 2 ) R-22 Many more R-407C blends …. • • • • Methyl Chloride (CH 3 Cl) R-502 R-410A • HCs CO 2 Societal Demands Continue to Drive Refrigerant Innovations 1

Refrigerant Transitions Past CFCs R-12, R-11, R-113, R-500, R- 502 more… Transitional HFCs & HCFCs R-22, R-134a, R-410A, R- 123 more… Next-Generation HFOs & Blends R-1234ze, R-1233zd, R- 513A, R- 514A… Refrigerant selection focused on minimizing overall impacts What is Driving Action? Dramatic global growth of high-GWP HFCs Alignment with Support to Sign Montreal Protocol Amendment 2

Global Consumption of HFCs Source: UNEP Ozone Secretariat Fact Sheet 2 12% “Overview of HFC Market Sectors” (Oct 2015) R-125 25% 79% 7% R-134a R-134a RACHP 2% R-125 R-32 R-410A Foam 40% 0.3% Markets R-32 13% Aerosals Using HFCs Fire Protection R-143a R-143a Solvents Total Metric Tons 9% Other R-152a R-152a HFCs 6% Other HFCs 7% Total Metric Tons 7% 86% 4% 3% RACHP Foam 0.0% Aerosals Fire Protection Percent of Tons of CO 2 Solvents Global HFC use of Refrigerants in RACHP Refrigeration, Air-Conditioning, Heat Pump Refrigeration Commercial 35% 73% Industrial Refrig 20% Air-Conditioning 65% 5% 2% Transport Domestic 36% Air-Cond Mobile 15% Chillers 4% Air-to-Air Heat only HP 45% Source: UNEP Ozone Secretariat Fact Sheet 2 “Overview of HFC Market Sectors” (Oct 2015) 3

Actions Taken in Mobile Air Conditioning European Environment Agency European Union F-Gas Regulations Corporate Average Fuel Economy (CAFE) 1-1-2013 de facto ban on R-134a in newly type- The 2012-2016 Standards offer credits for using low-GWP approved vehicles per Directive 2006/40/EC on refrigerants other than R-134a: mobile air conditioning ~ 3-4 MPG for changing refrigerant • ~ 5 MPG for overall system changes • Vehicles using R-1234yf refrigerant (North America) R-1234yf in 7 million cars by 2016 Auto Industry, shipping cars with R-1234yf starting in 2011 Need for Refrigerant Choice Retail Food 2017 Government Action on Setting Phase-Outs on HFCs R-404A, R-134a Propellants 2018 R-134a, R-227ea 2019 RULING: Vacated by 2020 Automotive district Court of Appeals Proposal R-134a Proposal 2021 RULING: Vacated by All AC Equip HFC w/ GWP > 750 • Retail Food Refrigeration • district Court of All Air Conditioning • - Jan 1, 2017 Canada to prohibit Equipment 2022 Appeals equipment high GWPs • Propellants & Aerosols • Using HFC’s with • Commercial Refrig 2023 - Jan 1, 2018 • GWP>750 Centrifugal Chillers GWP>1500 - Jan 1, 2024 • All Chillers Automotive 2024 • Starting R-134a, R-410A • Chillers - 2021 model year • - Jan 1, 2021 Positive Displacement GWP>700 2025 Chillers Chillers - Jan 1, 2024 GWP > 700 More to come… 4

Montreal Protocol HFC Amendment Agreement Kigali Amendment – Dubai Pathway on HFCs – Global Transitions Based on GWP October 15, 2016 Nations, Fighting Powerful Refrigerant That Warms Planet, Reach Landmark Deal KIGALI, Rwanda — Negotiators from more than 170 countries on Saturday reached a legally binding accord to counter climate change by cutting the worldwide use of a powerful planet-warming chemical used in air-conditioners and refrigerators. The World has Spoken… Phase Down HFCs Montreal Protocol HFC Amendment Agreement Kigali Amendment - Global Transitions Based on GWP October 15, 2016 USA, Canada… A2 Countries (Developed) 1 A5 Countries (Group 1) A5 Countries (Group 2) GCC 2 Established Baseline Quantity 90% 90 90 90 80% 80 70% 70 70 60% 60 50% 50 40% 30% 30 20% 20 20 15 15 10% 2046 2048 2016 2018 2020 2022 2024 2026 2028 2030 2032 2034 2036 2038 2040 2042 2044 Base Line A2 2011 Base Line A5 “1” Base Line A5 “2” to 2013 5

Montreal Protocol HFC Amendment Agreement 20.0M Kigali Amendment 17.5M Max Allowable HFCs (tonnes CO 2 – eq) Proposed Domestic Regulations 15.0M 12.5M 10.0M 7.5M 5.0M 2.5M Comparison of Max Allowable HFC Consumption AHRI Letter to Executive Branch Support of Congressional Action Vice President-Elect Mike Pence December 21, 2016 … action should be taken to enable U.S. industry to solidify its position as the global leader of innovation, job creation, and production of energy efficient products and equipment. The industry encourages the following actions in pursuit of that goal. • Submit the Kigali Amendment on the usage of hydrofluorocarbons to the Montreal Protocol to the Senate for ratification. AHRI, firmly support a number of current programs and regulations that bring predictability and consistency to our marketplace. • Maintain the Environmental Protection Agency (EPA) Significant New Alternatives Program (SNAP) as established under Section 612 of the Clean Air Act. The EPA’s ability to list alternative refrigerants by issuing new rules and maintaining previous rules continues to allow for flexibility in our members’ product designs while pursuing health and safety for consumers in the marketplace. Industry Supports Montreal Protocol HFC Amendment 6

US EPA to Tighten HFC Regulations Changes to Section 608 Refrigerant Management Regulations Current EPA Final Ruling CFCs, HCFCs, HFCs & HFOs Covered CFCs & HCFCs (Including all blends) > 5 lbs. for disposal Recordkeeping > 50 lbs. > 50 lbs. for service/repair 35% 30% Industrial Process Ref: Industrial Process Ref: Allowable 35% 20% Leak Rates Commercial Ref: Commercial Ref: (systems >50 lbs.) 15% 10% Comfort Cooling: Comfort Cooling: If allowable leak rate is exceeded, then Leak 50-500 lbs. – annual inspections None Required Inspections > 500 lbs. – quarterly inspections ≥ 125% charge loss (in a calendar year), Chronic Leaks None Required detailed reports must be filled (find & repair equipment) https:// www.epa.gov/section608/revised-section-608-refrigerant-management-regulations Appeal in having leak-tight machines is a real advantage HVAC Industry Next Transition Begins Past Transitional Future Next- Generation Refrigerants now available… 2L refrigerants; range from 0-10 cm/sec . Low Pressure Medium Pressure High Pressure BV represents “Burning Velocity” of BV 0.0 BV 1.5 BV 3.0 BV 3.8 BV 6.7 Refrigerant Efficiency All variables held constant for comparison 9.0 2L 2L 2L 2L 2L 2L 2L 2L 2L 2L 8.5 (COP) 8.0 Non- Non- Non- ASME ASME ASME 7.5 R-11 R-123 R-245fa R-1233zd R-514A R-12 R-134a R-513A R-1234ze R-1234yf R-22 R-410A R-452B R-454B R-32 325 Operating Pressure 275 225 (psig) 175 125 75 25 -25 Industry available choices offer high efficiency options 7

Flammability Properties Vary Class 3 Class 2 Class 1 "Highly Flammable" "Lesser Flammable" “Non -Flam" Class 2L “ Slightly Flammable " Visual Examples of Burning Velocity Differences with 2L Flammable Refrigerants R-1234yf R-32 Burning Velocity Burning Velocity 6.7 cm/sec 1.5 cm/sec Minimum Ignition Energy Minimum Ignition Energy >30 mj >5000 mj Burn Velocity Differs Between 2L Refrigerants 8

ANSI/ASHRAE Refrigerant Standards How are they related Standard 34 Standard 15 State Law Safety Standard of Model Code Classification Care “enforceable” Several Steps Before Code Adoption Safety Standards and Building Codes Revisions underway to enable application of next-generation refrigerants When can we apply these new refrigerants? 1. 2016 ASHRAE 34 2. SNAP-approved (U.S.) 3. Standards and codes? A1/B1 (non-flammable ) options… TODAY! ( no standard or code changes required) A2L/B2L (slightly flammable) options …. in addition to 1 & 2 above: OUTDOOR INSTALLATION: INDOOR INSTALLATION: o o 2017 UL 60335-2-40 Ed. 2 2017 UL 60335-2-40 Ed. 2 o 2018 model mechanical codes o 2019 ASHRAE 15 ( e.g. ICC and IAPMO ) o 2021 model mechanical codes o States, with 2017 UL 60335-2-40 Ed. 2 ( e.g. ICC and IAPMO ) o States, with 2021 model codes Non-flammables – today. Outdoor 2L application – with SNAP approval. Indoor 2L application – with 2021 model codes. 9

Refrigerant Choices & Comparison Screw & Centrifugal Technology Options Multiple, Next- Gen Refrigerants available… Today! High Pressure Replacements Driving Factors Blend • Performance Blend 26% R-1234yf • Safety 31% R-1234yf 7% R-125 R-452B R-454B 69% R-32 67% R-32 R-32 • Cost All Current High Pressure Alternatives are 2L 10

Recommend

More recommend