The CMS GEM Project Install triple-GEM detectors (double stations) in - PowerPoint PPT Presentation

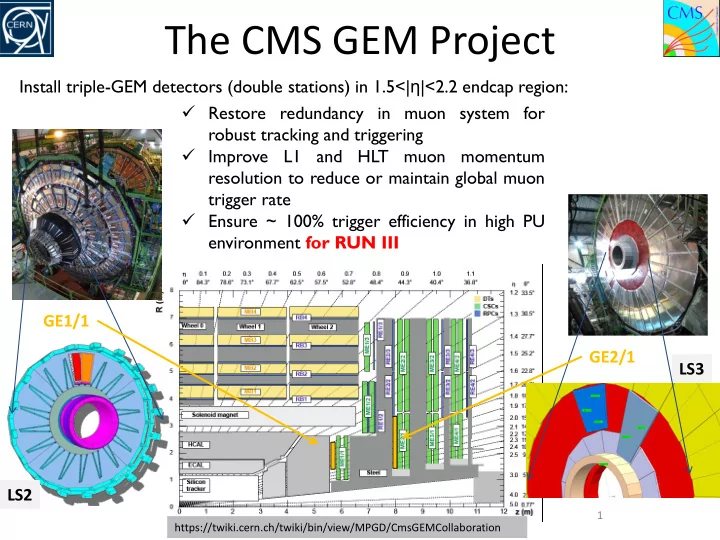

The CMS GEM Project Install triple-GEM detectors (double stations) in 1.5<| |<2.2 endcap region: Restore redundancy in muon system for robust tracking and triggering Improve L1 and HLT muon momentum resolution to reduce or

The CMS GEM Project Install triple-GEM detectors (double stations) in 1.5<| η |<2.2 endcap region: Restore redundancy in muon system for robust tracking and triggering Improve L1 and HLT muon momentum resolution to reduce or maintain global muon trigger rate Ensure ~ 100% trigger efficiency in high PU environment for RUN III GE1/1 GE2/1 LS3 LS2 1 https://twiki.cern.ch/twiki/bin/view/MPGD/CmsGEMCollaboration

Possible ME0 Being investigated GMM - Archana Sharma - 3/2/2014 2

Gas Electron Multiplier (GEM) Combine triggering and tracking Rate capability : 10 5 Hz/cm 2 Spatial/Time resolution: ~ 100 m / ~ 4-5 ns functions Efficiency > 98% Enhance and optimize the readout Gas Mixture: Ar-CO 2 -CF 4 (non flammable mixture ) ( η - φ ) granularity by improved rate capability GEM foils developed using PCB manufacturing techniques V=const. Large areas ~ 1m x 2m with industrial processes (cost eff.) Each foil (perforated with holes) is 50 μ m kapton sheet with copper coated sides (5 μ m) Typical hole dimensions : Diameter = 70 μ m, Pitch = 140 μ m, ~400 V 50-80kV/cm 3

Motivation: Exploiting GEM-CSC Bending Angle View from the top of CMS down Preliminary Preliminary • An increased lever arm of the combined CSC+GEM system allows accurate measurement of the bending angle – Note that half of CSC-GEM chamber pairs are “close” and the other half is “far” (see the figure above) • Excellent discrimination power to distinguish soft muons from hard – Larger lever arm for “far” chambers provides even better separation Vadim Khotilovich (Texas A&M University) 4 Simulation Studies – Alexei Safonov and Anna Colaleo

CMS GEM Collaboration RD10.01 Project Milestones (i) OVER FOUR YEARS OF R&D • 2009-2010 – Small prototypes, bench tests; picked GEMs among MPGDs for further study – Established space and time resolution achievable – First Large-area GEM foils produced with Single Mask technology – First large-area GE1/1 prototype; beam test • 2011 – Second redesigned GE1/1 prototype (smaller gaps b/w GEMs) – “ GEM Collaboration (GEMs for CMS) ” constitutes itself in May CMS week (76 collab. from 15 inst. ) – Summer beam tests (including first test in CMS test magnet) – Established 100µm (300µm) res. with analog (binary) r/o chip – NS2 GEM foil assembly technique w/o spacers – Preliminary electronics design starts 5

CMS GEM Collaboration Project Milestones (ii) 2012 • Beam tests – Magnetic Field Operation and fine space and time resolution on large size established • Working Groups (Physics, Trigger Simulations, Integration Services, Electronics and DAQ, Detector HW) with weekly meetings • Third GE1/1 prototype designed (new GEM design “ NS2 ” ; and readout), 5 detectors produced! One more to be assembled outside of CERN • Started GIF long term aging test • Collaboration Expanded 42 Institutions, 183 collaborators EOI 2013 • GE1/1 - 6 Detectors produced in 2013 (Two outside CERN); 6 potential production sites • Beam test at Fermilab with GE1/1 + 6 smaller detectors • Long term tests + Materials study Launched • Electronics and DAQ groups take big steps : proto FPGA /GEB/uTCA in hand • TDR requested by CMS management; Slice Test Approved (DESY MB 2013) 2014 • GE1/1 – 10 “Final” detectors launched for production: 3 Long on way • TIF Area being readied for “Proto - Slice Test” 6

CMS Project Achievements Together RD51 and CERN Surface Treatment Workshop Detector efficiencies above 98% Spatial resolution of about 290 μ m with VFAT2 (digital) and <110 μ m APV (analog) readout chip Time resolution of 4ns Operation of GEMs in magnetic field Validation of single-mask technology Production of large area GEM foils New self-stretching technique for GEM assembly 7

Full-size GE1/1 Detectors Developments in Time 2013/14 2010 2011 2012 2013 Generation I Generation II Generation III Generation IV Generation V The first 1m-class First large detector The first self- The current The upcoming detector ever built but with 24 readout stretched sans- generation that detector version still with spacer ribs sectors (3x8) and spacer detector, but we have built two that we will install. and only 8 sectors 3/1/2/1 gaps but with the outer frame of at CERN so far, One long and one total. Ref.: 2010 IEEE still with spacers still glued to the with four more to short version. (also RD51-Note- and all glued. Ref.: drift. Ref.: 2012 IEEE come from the Optimized final 2010-005) 2011 IEEE. Also N14-137. different sites. No dimensions for RD51-Note-2011- more gluing max. acceptance 013. whatsoever. and final eta Several papers segmentation. MPGD 2013 / 10 Detectors IEEE Launched for 2014 Luigi Benussi and Marcus Hohlman 8

1 st Generation I - GE1/1 Detector Excellent performance observed: ≥ 98% efficiency 230 µm resolution ( pitch/ 12 for binary electronics) uniform performance in different sectors Track residuals Efficiency CMS/GE11_efficiency_p1_09012011 SINGLE MASK ge11_residuals CMS/GE11_SpRes_p1_09012011 RUN = 175 HV = 4.50 kV I = 738.90 uA Thr = 40 V u η = 99.5% Position = P1 Gas: Ar/CO 2 (70:30) RUN = 37 – 181 Thr = 40 V u Lat = 14 Position = P1 9

2 nd GE1/1 Detector (2011) Successful data taking with analog APV chip and Scalable Readout System in addition to TURBO/VFAT2 DAQ system Measured resolution σ x <103 μ m in section with smallest pitch Strip cluster size μ - / π - beams <cluster size> = 3.4 Δx hit measurement : Tracker GEM vs. CMS full-size GE1/1 <cluster size> = 2.6 10

GEM Foil Stretching (III) Current state-of-the-art: Self-stretching assembly without spacers (CERN) Readout Tightening the PCB horizontal screws tensions the GEMs GEMs Drift electrode Detector base pcb only glue joint in assembly Allows re- opening of assembled detector for 2012 repairs if needed

Generation IV - GE1/1 Detectors (2012) GEM foil in inner frame assembly GEM foil with inner & outer frame Inside of readout board with O-ring seal Base pcb with drift electrode No spacers in active volume -sector with 384 radial readout strips 12

CMS GEM Aging Tests at CERN GIF J. Merlin J. Merlin

DAQ and Electronics Global Requirements on electronics: provide necessary input from all GEM detectors to Muon Triggering and Tracking GEM detectors: Design optimized for gas detectors, in particular GEMs Triggering: Provide “Fast OR” trigger information with granularity of 2 or more channels to send locally to CSC Trigger Mother Board Timing resolution <8ns Tracking: Provide full granularity tracking data on receipt of a LV1A Be compatible with CMS trigger upgrade possibilities: • LV1A latency < 20 μ s • LV1A rate < 1MHz Paul Aspell & Gilles de Lentdecker 14

DAQ and Electronics On Detector Off Detector GEM_PCB GBT protocol VFAT3/GdSP Or 8b/10b encoding ? FPGA/ m TCA crates GBTs Trigger AMC13 GLIB Links to CSCs DAQ Ser/Des Optical links @ 3.2Gbps DCS TTC DC/DC converters 2 Bidir. optical link @ 3.2 Gbps Power Supplies LV HV P. Aspell & G. de Lentdecker 15

VFAT3 VFAT3 chosen for the 2016 Slice Test and GE1/1 full installation during LS2 VFAT3 analog discriminator will use CFD or TOT to correct time walk VFAT3 STT version (Separate Tracking & Triggering) GEM OptoHybrid contains FPGA performing “concentrator” and driving optical link @ 3.2Gbps; FPGA programming via the GBT P. Aspell 16

Trial Installation in CMS - 2013 17 Andrey Marinov and Antonio Conde Garcia

GE1/1 Super-Chamber cable path GE1/1 Super-Chambers slot We have ~ 20 mm clearance in height 09/02/2014 A. Marinov 18

GE1/1 Slice Test in 2016: YE-1 GE1/1-Slice TEST SLOTS 1-2; 35-36 Gas Racks 19

Integration Tests at TIF: GEB & Hybrids • Measurement setup is functional at TIF. – Able to readout hybrids using TURBO readout system – Waiting for Optohybrid V1 joonas.petteri.talvitie@cern.ch

GE1/1 Mockups at TIF Barthel Phillips : Aachen 2013 21

Overlapping 22

Readiness for Slice Test : Integration The “Installation” in TIF is done on the Installation at P5 will take place after middle of optical table. March Alignment trials are foreseen, Zoltan and Validation of the mechanics. team involved Validation of the services paths Will be used for the new GEB and Strips Commissioning of the gas lines with Ar. boards development in order to validate the mechanics 23

Cosmic stand and DAQ Ongoing Work Cu Box test stand for Chamber QC xDAQ Developments started Cosmic stand mechanics preparation Gas system is ready, Additional bottles have been ordered, including big CF4 cylinder Team being developed Clear plan needed from this workshop: uTCA Crate in Lab Andrey Marinov GLIB AMC13 Sasha Zakharov Jared Sturdy Brian Dorney + 2 Students (Phd/Technical) Welcome to participate ! 24

GE1/1 Slice Test Schedule Production and Slice Slice and QC of QC of detectors installation trigger Production First prototype commissioning GE1/1 of VFAT3 chambers with final electronics 2014/15 YETS 2015/16 2016/17 2017/18 2018/19 Full installation Full-production of of GE1/1 with 25 chambers and electronics started final electronics

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.