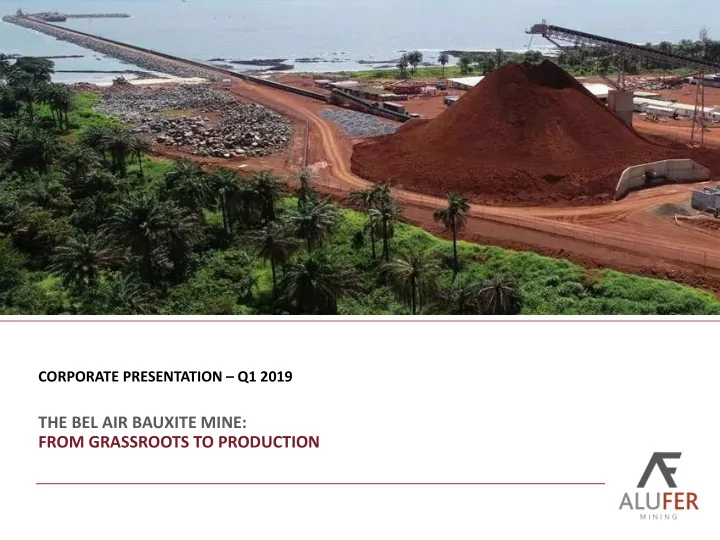

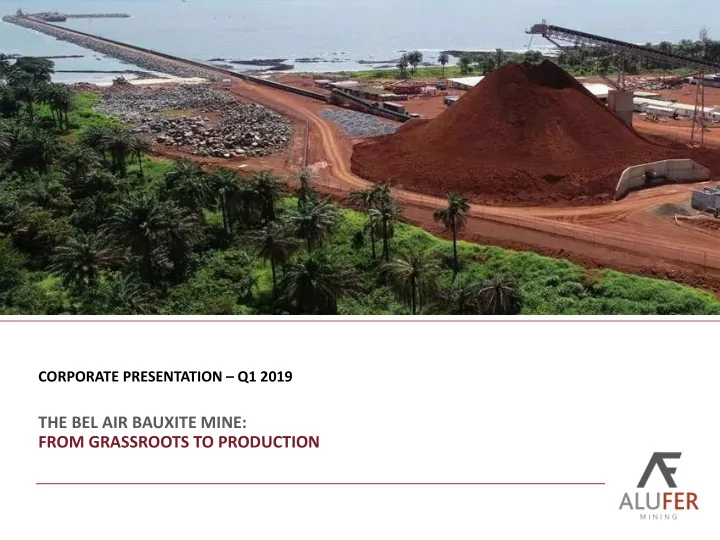

CORPORATE PRESENTATION – Q1 2019 THE BEL AIR BAUXITE MINE: FROM GRASSROOTS TO PRODUCTION

COMPANY OVERVIEW ALUFER IS ONE OF THE MOST ATTRACTIVE BAUXITE MINING COMPANIES GLOBALLY Commenced production at flagship Bel Air Project in Guinea • ON TIME, UNDER BUDGET, LTI FREE Rare development story: • Alufer discovered the deposit through maiden drilling in 2011 • Completed detailed feasibility, social and environmental studies • Secured financing in 2016 • Commenced construction in 2017 • Commenced production in Q3 2018 • On target to deliver steady state production – 5.5mtpa BEL AIR PROJECT: 146 million tonne JORC resource; logistical advantage LABE PROJECT: 2.5 billion tonne JORC resource; in top 3 largest bauxite deposits in the world Focused on delivering a long term, sustainable mining operation and creating value for all stakeholders 2

CONSTRUCTION - FINANCING AND COMPLETION In December 2016, Alufer successfully secured a $205m financing package from a consortium of new investors and existing shareholders • Significant achievement in challenging markets US$125m of Convertible Loan Notes and Equity • Resource Capital Funds • The Africa Finance Corporation • Orion Mine Finance US$80m Senior Debt Facility • Orion Mine Finance Offtake Agreement with Orion Mine Finance • Working with Alufer to market the bauxite Construction commenced in January 2017 and first ore on ship was delivered in August 2018 – 18.5 month phase Officially inaugurated by His Excellency Alpha Conde in November 2018 3

BAUXITE OVERVIEW BAUXITE IS THE PRINCIPAL ORE OF ALUMINIUM • Bauxite is the main commercial mineral from which aluminium oxide is extracted, which in turn is smelted to form aluminium metal: 5t Bauxite Ore 2t Alumina 1t Aluminium Consumers Bauxite Alumina Aluminium and mining refining smelting Fabrication • Aluminium demand continues to drives alumina and bauxite growth - medium to long term fundamentals are still strong • Demand continues to grow in key sectors including transportation, construction, power, packaging and consumer products • Guinea produces high quality ore due to tropical location • Seaborne bauxite market - circa 100 million tonnes a year • Bel Air bauxite is a high value product: • Well suited to low temp refinery • Low reactive silica - notable advantage from Value in Use perspective • Low deleterious elements 4

PROJECT OVERVIEW - OPERATIONAL SUMMARY SIMPLE LOGISTICS SET-UP: MINING - SHORT HAUL - CAUSEWAY CONVEYORS - TRANSHIPMENT Built a dedicated haul road, export facility, port and berth and control full production chain from pit to ship Stage 2: Short Haul Stage 3: Export Facility Stage 4: Shipping Stage 1: Mining • Transhipment handled • • Ore is stockpiled and DSO material is mined • Material is then handled via conveyor via self-propelled from a minimum of 2 transported via truck barges and pits at a time over a 1.2km causeway from the pits to the • and loaded onto barges transhipment vessel Open cast, strip export facility at the • Provides access from mining with surface (TSV) coast • Ocean Going Vessels miners shore to suitable water • Low opex, minimal re- • depth for 10,000 DWT loaded 32 km offshore Enables ongoing handling, high • Significant storage rehabilitation during barges efficiency capacity on TSV LOM THE PROCESS HAS BEEN OPTIMISED FOR CAPEX, OPEX AND THE OPERATING ENVIRONMENT 5

SURFACE MINING AT PIT, EXPORT FACILITY AND CAUSEWAY 6

LOADING THE BARGES AND TRANSHIPPING 7

SOCIAL AND ENVIRONMENTAL ALUFER IS COMMITTED TO PROMOTING & DELIVERING SUSTAINABLE DEVELOPMENT • Alufer is committed to continuously improving the operational performance of the project: • To establish a culture for safety, productivity and efficiency • To enhance the project’s social and environmental benefits • Alufer adopted the IFC Performance Standards along with the Equator Principles as best practice for Bel Air • The site is regularly audited to ensure compliance with these standards • Ongoing work includes: • Baseline and integrated impact assessments, social and environmental management plans, monitoring of noise, dust, water • Detailed Land Access and Resettlement Plan • Biodiversity Management and Action Plans • Over 2,000 meetings were held with circa 20,000 people from the communities throughout Construction - will continue going forward • Stakeholder engagement will be a core focus for the life of the project 8

COMMUNITY INITIATIVES 40 COMMUNITY DEVELOPMENT PROGRAMMES COMPLETED TO DATE – LOOK TO OFFSET IMPACTS WITH LONG TERM BENEFITS Funded by Alufer, shareholders and third parties COMMUNITY PROJECTS Education: Building of schoolrooms and teacher accommodation Water: Installation and repair of wells to ensure potable supply Health: Building of health posts, maternity units and provision of equipment Waste Management and Recycling Initiatives Solar: Generation of power for domestic and public lighting LIVELIHOOD PROJECTS Market Gardens : Provide high value produce (eggplant, chilli, cashews, pineapples) for the community and site Local Business : Training, assistance and support of local enterprise Salt Production: New methodology taught and storage room built 9

UPSKILLING THE WORKFORCE Alufer is fully compliant with employment quotas within the Mining Convention and Mining Code 95% of the workforce is Guinean - Alufer is committed to employing as many people from impacted villages as possible Throughout Construction Alufer and its contractors ran training programmes to upskill the workforce and certify them for future employment Will continue to develop skills for people from local communities through contractors: • Brute, Mining Contractor, is training 180 people over two years to qualify in semi-skilled jobs across the project • SMT, Transhipment Contractor, has launched a maritime scholarship programme 10

KEY MANAGEMENT • Metallurgical Engineer with 35 years of operational and project experience • Bernie Pryor Extensive African experience in project acquisition, evaluation and development, construction and mine Chief Executive Officer operations • Was Head of Business Development with Anglo American Plc, also serving as CEO of Anglo Ferrous Brazil Inc • Chartered Accountant with 15 years experience in the mining sector • Rachel Rhodes Previously with Anglo American and CFO of London Mining • Chief Financial Officer Extensive background in raising project finance and taking mining operations through construction to production • Great deal of experience in government liaison and representation for a number of companies inGuinea Lamine Toure • Has worked across a variety of sectors – mining, textiles and urban project development Vice-Chairman, BAM • Previously worked with Mobil, Global Alumina, Koumba IronOre • Geologist with 20 years across the industry – exploration, development and production Kevin Mclean • Previously with Shangdong Iron and Steel, African Minerals and Fortescue Metals Project Director • Expertise in optimising and delivering efficient mining operations • Broad commercial experience - over 12 years working in the resources and power sectors Tristan Clarke • Previously with Shangdong Iron and Steel, African Minerals and Anglo American Commercial Director • Specific experience in commodities marketing, complex negotiations, supply chain and corporate strategy • Over 30 years experience in HR management and strategy, organisational development and governance Denis Leblanc • Previously with SRD Nordgold, CBG and Xstrata Nickel HR Director • Strong focus on balancing team work with individual development and business objectives • Over 17 years experience working in sustainability within the mining and development sectors in Africa. Jason Peirce • Wide range of expertise in social and environmental assessments, community relations, stakeholder E & S Director engagement, Previously with INSUCO, Anglo Gold Ashanti and the Belgian Development Agency 11

Recommend

More recommend