SERIO Printing Systems page 38 Closed Loop Print Head Pressure Control Pressure on stencil will be checked and adapted every 40 ms.

SERIO Printing Systems page 39 High Precise Squeegee Head System Default value Closed Loop System Software input No mechanical limitation of the squeegee stroke REAL value SET value The squeegee can follow the surface of the substrate No product specific down stop set necessary Pressure value (squeegee pressure) Squeegee pressure controlled every Pneumatic cylinder in 40ms, if different from the set value the squeegee head directly adjusted during the print stroke Stencil / screen frame Substrate with uneven surface structure Stencil / screen

SERIO Printing Systems page 40 High Precise Squeegee Head System Default value Closed Loop System Software input No mechanical limitation of the squeegee stroke REAL value SET value The squeegee can follow the surface of the substrate No product specific down stop set necessary Pressure value (squeegee pressure) Squeegee pressure controlled every Pneumatic cylinder in 40ms, if different from the set value the squeegee head directly adjusted during the print stroke Stencil / screen frame Stencil / screen Substrate with uneven surface structure

SERIO Printing Systems page 41 High Precise Squeegee Head System Default value Closed Loop System Software input No mechanical limitation of the squeegee stroke REAL value SET value The squeegee can follow the surface of the substrate No product specific down stop set necessary Pressure value (squeegee pressure) Squeegee pressure controlled every Pneumatic cylinder in 40ms, if different from the set value the squeegee head directly adjusted during the print stroke Stencil / screen frame Substrate with uneven surface structure Stencil / screen

SERIO Printing Systems page 42 Closed Loop Print Head and iQUESS › Real Closed Loop functionality due to two independent print heads with permanent compensation of pressure differences › Compensates uneven substrate surfaces › Tool free i ntelligent Qu ick E xchange S queegee S ystem iQUESS – For fastest product changeover

SERIO Printing Systems page 43 iQUESS – Quick Exchange Squeegee System › Tool free intelligent Quick Exchange Squeegee System › Fast and easy operation from front side › Upgradeable on most existing systems › No additional cables or pneumatics required

SERIO Printing Systems page 44 Optimized Squeegee Side Dams › Special design automatically seals to stencil › No manual adjustment required › Minimize paste leakage › Less waste › Can be upgraded on nearly all EKRA squeegees

SERIO Printing Systems page 45 Printing with Squeegees › Less paste causes miss printed substrates › To much paste causes bridging's Print direction Squeegee Frame Paste Stencil Pad PCB

SERIO Printing Systems page 46 Paste Height Control › 3 level’s selectable : › Low level for interrupting production › Second level to refill / reload paste › Third level indicates excessive paste on stencil › System measures in between the squeegees › Paste can not influence the sensor › Maintenance free › Works for different type of paste, adhesive, etc. This is a real USP – only with EKRA

SERIO Printing Systems page 47 Automatic Dispenser › Fully programmable for amount, frequency and placement of deposits › Automatic dispense depending on paste height › Available for 650g or 1200g paste cartridges › Single or dual cartridge capability available › Automatic paste shearing and cartridge sealing avoids drips after dispensing › Paste Dispenser “Straight out of the jar ” Reload paste while printing increases throughput

SERIO Printing Systems page 48 Paste Dispenser “Straight out of the jar” › New type paste dispenser › Dispensing paste out of the standard container › Usable for most jar types Put used paste back into the jar

SERIO Printing Systems page 49 Stencil Cleaning › Clean stencil underside is required for excellent printing results › During printing paste pollutes around the apertures › Insufficient cleaning can cause bridging's, solder balls, failures

SERIO Printing Systems page 50 SERIO Stencil Underside Cleaning System › Standard cleaner, iROCS light, iROCS and iROCS advanced › Easy wipe exchange › Vacuum side channel blower for excellent cleaning results and low energy consumption › Electronic gear including paper feed sensor to ensure constant transport › Automatic sprinkler settings ; just moistening as long the substrate is › No pump to dispense cleaning agent Environment friendly

SERIO Printing Systems page 51 iROCS – Integrated Rapid Oscillating Cleaning System › iROCS Light › Oscillating movement selectable › Faster cycle time (30% with two sweep cleaning) › iROCS › Oscillating movement selectable › Faster cycle time (30% with two sweep cleaning) › Wipe exchange for NON STOP operation! 30% faster than standard cleaning

SERIO Printing Systems page 52 iROCS Advanced › Cassette system for cleaning wipe, the fastest and easiest way to exchange the cleaning wipe › One cassette in use › Second cassette outside for preparation › Storage for two cassettes ; no separate table needed when exchanging cassettes › Cassette exchange during automatic operation within 20 seconds -> no stop of production required

SERIO Printing Systems page 53 SERIO Stencil Underside Cleaning System › Fast & superior stencil underside cleaning › Environment friendly usage of consumables › Constant wipe feed › Wipe exchange w/o machine stop › Exchange wipe w/o stencil movement

SERIO Printing Systems page 54 SIMPLEX – Stencil Mounting Semi Automatic Optical Target Full Automatic Stencil Loader Semi Automatic Mechanical Hard Stop

SERIO Printing Systems page 55 Fastest Product Change Over › For fastest product change overs 1. Call print program 2. Slide in the stencil all the way to the optical target or hard stop 3. Put Past on the Stencil 4. Mount Squeegees 5. Close the cover 6. Run in PCB 7. Systems verifies the fiducials › Start the automatic run Fastest and easiest way to mount stencils

SERIO Printing Systems page 56 Machine set-up › Wrong set up of tools, squeegees, stencils or materials cause problems Cost Loose of Image Injury of life Damage to property RECALL

SERIO Printing Systems page 57 Process Control using DMC Code › Recognition and analysis of DMC on PCBs and / or stencils › DMC can be linked with the SPC file for product traceability › No additional equipment is required in front of the Printer Traceability

SERIO Printing Systems page 58 Set Up Verification – Barcode & DMC Code › Set up control for easy printer configuration › Use mobile scanner for setup of tools and consumables › Up to 10 different objects selectable › Process verification for stencils, squeegees, paste and PCB support › All data stored within the print recipe

SERIO Printing Systems page 59 Set up verification / SIMPLEX › The system guides the operator through the set-up procedure › All recipe required components must be scanned › Full flexible solution, programmable › Easy to use and process safe Set up verification avoids wrong operation

SERIO Printing Systems page 60 Quick Set-Up S10 Storage System › Storage of squeegees directly on the machine › Fast and easy access to › Support blocks › Paste › Wipes › iPAG glue cartridges › Upgradeable of existing systems Tools & materials where they are needed

SERIO Printing Systems page 61 Alignment and Inspection › Precise alignment of PCB to stencil is essential for highest printing accuracy › EKRAs unique camera with EVA”EKRA Vision Alignment” technology ensures best results › Special illuminations give best in class results for fiducial recognition › Special camera systems with red, white or blue illumination › Extraordinary camera including polarizing filter complete the camera variety

SERIO Printing Systems page 62 Camera Field of View › 4 different FoV are available › High resolution camera, very small FoV (6µm) › High speed camera, large FoV (21µm) LARGE › Inspection speed depends on the MEDIUM FoV SMALL High-Res 22 x 22 20 x 16 12 x 9 8 x 6 Cameras for every purpose

SERIO Printing Systems page 63 SIMPLEX – Fiducials › Product image will be scanned automatically by the machine › Define / select up to 5 fiducials with your fingertips › Auto detection of shape and size › Learn the fiducial Fiducial set-up in less than 30 seconds

SERIO Printing Systems page 64 EVA™ EKRA Vision System › EVA ™ is using 2 cameras and 2 different types of illumination › LED spot light source and LED diffused light source › Fast inspection up to 3 pictures (2D) per second possible › 2½ D Inspection with short cut and bridging detection Stencil Reflector Cube Upper Diffused Light Source (Optional) Light Source 1 (Spot) Light Source 2 (Spot) CCD Camera CCD Camera Lens Lens Lower Diffused Light Source Illumination Cube Substrate

SERIO Printing Systems page 65 EVA ™ & 2½ D Post Print Inspection System CCD Camera Diffused light Diffused light: Substrate Solder paste appears bright , due to LED light reflection Pad Solder paste Diffused light is ON (Appears bright as light is and spot light is OFF. reflected into the camera) CCD Camera Light Pad scattered Spot light: surface Substrate away due to reflects Solder paste appears dark , solder balls light deflecting due to light deflection back to Pad light camera Solder paste Diffused light is OFF (Appears dark as light is and spot light is ON deflected away from camera)

SERIO Printing Systems page 66 EVA ™ 2½ D Post Print Inspection System CCD camera Diffused light Solder Paste appears bright due to reflection. PCB No solder area reflects Pad different, more dark. Diffused light ON and spot light OFF Solder paste appears dark , CCD camera due to deflection Pad surface PCB reflects light back Deflection, due to round No solder area reflects to the camera solder balls surface different, more bright. Pad Diffused light OFF and spot light ON › In case of solder paste height deviation and missing paste the reflection of the paste changes. › This change will be identified by the vision system and a volumetric view of the solder paste will be achieved.

SERIO Printing Systems page 67 2½D-Post Print Inspection System Step 1: › Define the inspection region by touch and drag a frame › Teach in of the stencil apertures (master) independent from any aperture geometry. Tech in from stencil – no gerber data

SERIO Printing Systems page 68 2½D-Post Print Inspection System Step 2: ›„Learning“ of the solder paste by using the „ Auto paste teach in “ function (all available light settings will be adjusted automatically). › The grey scale analysis defines a characteristically reflection behaviour for this paste. ›This „Paste profile“ will be stored automatically in the program data. Automatic setting of histograms

SERIO Printing Systems page 69 2½D-Post Print Inspection System › Paste coverage and bridging will be detected at the same time 2 ½D inspection, see more than just coverage

SERIO Printing Systems page 70 2½D-Post Print Inspection System › Stencil inspection detects for paste clogging . › Auto trigger of stencil cleaning › Independent stencil / PCB inspection 2 ½D inspection, excellent price performance ratio

SERIO Printing Systems page 71 SPI Closed Loop that can do more. › Take the full advantage of your SPI › Minimize print offset due to board variations › Optimizing stencil cleaning › Realized with industry partners › KohYoung › Parmi › Pemtron › TRI › Viscom ›… EKRA offers an open platform for every SPI

SERIO Printing Systems page 72 Closed-Loop Print Offset Correction › Less deviation across the PCB manually disturb offset › Increased repeatability Offset X › Larger process window corrected correction OK › Minimizes print direction offset › Higher first pass yield Offset Y Automatic correction for ideal process conditions

SERIO Printing Systems page 73 Closed-Loop Dynamic Stencil Cleaning › SPI triggers for stencil cleaning › Increased quality @ less cleaning cycles › More stable process › Cleaning before defects occur › Increases throughput Automatic stencil cleaning for highest throughput

SERIO Printing Systems page 74 Closed Loop Printer SPI Troughput optimized by cleaning cycles, assumed 15seconds for Print & Handling 5500 5250 5000 4750 Throughput per day 4500 15 4250 4000 3750 3500 3250 3000 2 4 6 8 10 12 14 Cleaning ech x PCB Optimized quality and increased throughput using Closed Loop solutions

SERIO Printing Systems page 75 Double Side SMT Reflow Process › Tall or heavy components can twist or fall off during second reflow cycle › Adding adhesive and glue the components down

SERIO Printing Systems page 76 Adding paste at THT device holes › Add paste directly after printing to increase the fill grade of THT device holes No need for additional step stencils

SERIO Printing Systems page 77 iPAG – Paste and Glue Dispenser › Apply glue or paste directly after printing › Add paste on deposits where more solder is needed i.e. › THT, power components, shields › iPAG with temperature control for a better repeatable process › distance control for contact-free application of solder-paste › Single or Twin iPAG configurations possible Single / Twin iPAG, Heating, contact-free, interchangeable

SERIO Printing Systems page 78 iPAG – Jet › Jet dispensing for glue application › Dot size down to 0,5 mm* possible (*depending on materials) › Camera inspection of applied glue dots › 4 times faster then other dispense solution in printers › 20 dots in 6 seconds › 20 dots including inspection in 30 seconds iPAG Jet - the first jet dispenser within a printing system

SERIO Printing Systems page 79 iPAG – Jet Repeatability › Test Equipment: CeTaQ-Cm Controller › Dispense 25 times each 24 Dots on CeTaQ MLP09 Plate › Dot size 0,5mm › Glue Type: Heraeus PD 205-A

SERIO Printing Systems page 80 iPAG – Advantages › Fully programmable in dot size and position › Individual parameters for each dot › Inspection of applied dots › Laser distance control or stand off › SIMPLEX Programming › Various nozzle diameters to adapt various paste / glue types › Up to 1000 dots per recipe programmable

SERIO Printing Systems page 81 Next generation Components, the 03015 and beyond › printed 03015 structure in comparison with a human hair Component size, Component size, Lenght in mm Width in mm Metric code Imperial code 0201 0,2 0,10 03015 0,3 0,15 0402 01005 0,4 0,2 0603 0201 0,6 0,3 1005 0402 1,0 0,5 1608 0603 1,6 0,8

SERIO Printing Systems page 82 03015 – A NEW COMPONENT SIZE 300µm by 150µm › Yes we can! SERIO is ready for 03015 or 0201 › Conditions: Printer with high accuracy alignment system 12,5µm@6s and linear measurement scales at the camera axis › Stencil: stencil thickness 40 – 50µm, nano coated or plasma treated › Printing: Use normal print parameters › Paste: Type 5 is recommended, Type 4.5 is only limited suitable SERIO 4000 – ready for the future!

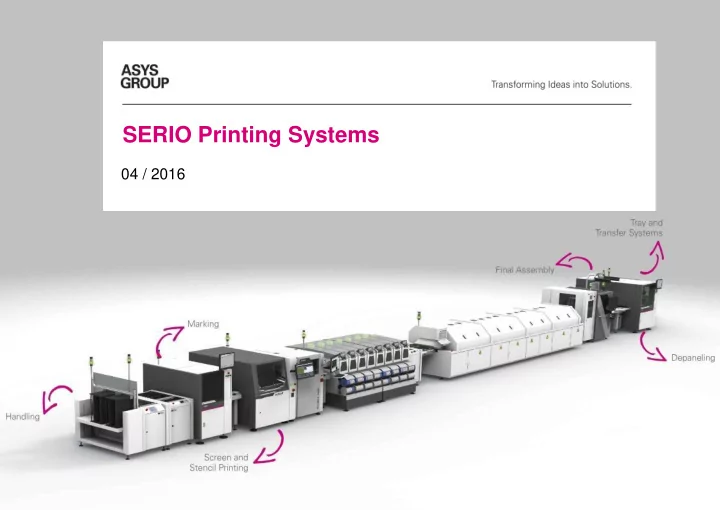

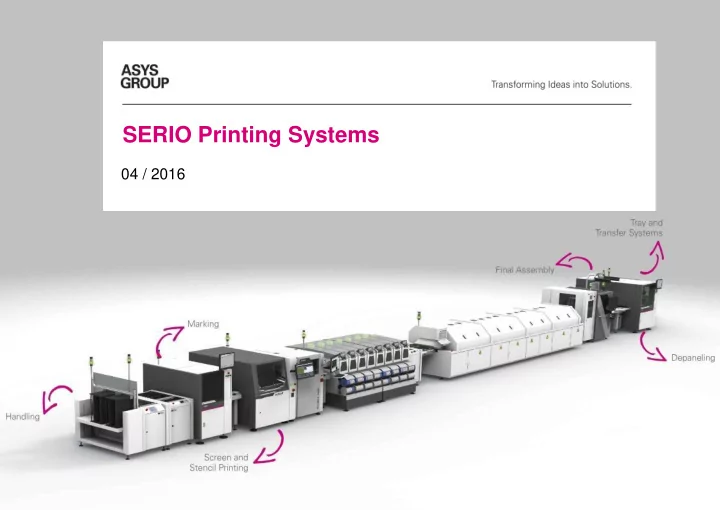

SERIO Printing Systems page 83 Agenda › ASYS Group / EKRA Company Overview › EKRA SERIO Printing Process › EKRA SERIO Printing Solutions › EKRA Quality Assurance › Q & A

SERIO Printing Systems page 84 Portfolio - from Manual to High Performance Inline

SERIO Printing Systems page 85 SERIO Portfolio - from Manual to High Performance Inline XM E2 SERIO 8000 SERIO 4000 SERIO 5000 X5 Professional SERIO – Define what you need!

SERIO Printing Systems page 86 Performance “in - line” X5 Professional 5 sec SERIO 5000 SERIES 7 sec SERIO 4000 SERIES 11 - 7 sec SERIO – define your performance!

SERIO Printing Systems page 87 XM PCB size XM 50 x 50 / 350 x 400 mm 0,5 – 6 mm PCB thickness PCB weight <20kg Cycle time Manual 300 x 300 – 590 x 590 Stencil frame size XM Alignment accuracy Manual Weight XM 85kg › Side clamping or vacuum print table › Pneumatic print head XM – simply start

SERIO Printing Systems page 88 E2 / E2XL PCB size E2 / E2XL 370 x 450 / 550 x 610 mm 0,8 – 6 mm PCB thickness PCB weight <20kg Cycle time Semi Automatic 300 x 300 – 620 x 740 / 740 x 920 Stencil frame size E2 / E2XL Alignment accuracy ± 10µm Weight E2 / E2XL 550 / 650 kg › Side clamping or vacuum print table › Screen print head › MOPS – Manual Optical Positioning System › For further options ask your EKRA specialist E2 – easy to use, high accuracy

SERIO Printing Systems page 89

SERIO Printing Systems page 90 SERIO 4000 – Back To Back PCB size 510 x 360 mm 0,2* – 4 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 11-7 sec Stencil frame size 738 x 738mm Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1100 kg › SIMPLEX user interface › Closed loop head › EVA ™ - EKRA vision alignment system › iQUESS – intelligent squeegee exchange system ›Optional “Mobile Package” with 20µm and enhanced print head SERIO 4000 BtB – Reduce to the Max *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO 4000 Back To Back SERIO Printing Systems page 91

SERIO Printing Systems page 92 SERIO 4000 Back to Back

SERIO Printing Systems page 93 SERIO 4000 PCB size 510 x 510 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 11 sec 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1200 kg › SIMPLEX user interface › Closed loop head › EVA ™ - EKRA vision alignment system › iQUESS – intelligent squeegee exchange system SERIO 4000 – SCALE IT UP! *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 94 SERIO 4000 Compact PCB size 510 x 510 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 11 sec 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1200 kg › SIMPLEX user interface › Preparation option upgrade › Closed loop head › iROCS light - Oscillating cleaning system › EVA ™ - EKRA vision alignment system › iQUESS – intelligent squeegee exchange system *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 95 SERIO 4000 Volume PCB size 510 x 510 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 9 sec 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1200 kg › SIMPLEX user interface › iROCS light - Oscillating cleaning system › Closed loop head › Vacuum option for print nest › EVA ™ - EKRA vision alignment system › Paste height detection with 3 levels › iQUESS – intelligent squeegee exchange system *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 96 SERIO 4000 Speed PCB size 510 x 510 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 7 sec 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1200 kg › Vacuum option for print nest › SIMPLEX user interface › Closed loop head › Paste height detection with 3 levels › iROCS – Non stop operation › EVA ™ - EKRA vision alignment system › iQUESS – intelligent squeege exchange system *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 97 SERIO 4000 Dual Lane PCB size 400 x 253 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Fixed Rails: 1 and 3 or 1 and 4 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 25µm@6Sigma Weight 1200 kg › SIMPLEX user interface › Special Dual Lane configuration › Closed loop head › EVA ™ - EKRA vision alignment system › iQUESS – intelligent squeege exchange system *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 98 Further benefit* › Supply of the bypass lane through the 1. printer During e.g. maintenance of the 2. printer – 1. printer is able to keep up production Power supply* and control* STOP Power supply* and control* * Only with ASYS Group complete solution

aa SERIO 4000 Multistep SERIO Printing Systems page 99

SERIO Printing Systems page 100 SERIO 4000 Multistep - Special developed system to print extra-large / long boars - i.e. LED application - Offers better print accuracy than printing the PCB at once - SERIO 4000 Multistep can process PCB from 100mm x 50mm up to 610 x 508mm single step - SERIO 4000 Multistep can process PCB from 611mm x 50 up to 1200 x 300mm in double step - SERIO 4000 Multistep can process PCB from 1200mm x 80mm up to 1500 x 200mm in triple step - There is no other system like this on the Market - Stencil design rules are available at EKRA - Special system based on the SERIO 4000 technology - but it is not possible to upgradeable a normal SERIO 4000 to Multistep

SERIO Printing Systems page 101 SERIO 5000 and SERIO 5000 Volume PCB size 510 x 510 mm 0,2* – 6 mm PCB thickness 0,1 – 2 kg PCB weight Cycle time 7 sec 450 x 450 – 800 x 900 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 20µm@6Sigma Weight 1200 kg › SIMPLEX user interface › iROCS light - Oscillating cleaning system › Closed loop head › Vacuum option for print nest › EVA ™ - EKRA vision alignment system › Paste height detection with 3 levels › iQUESS – intelligent squeegee exchange system *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

SERIO Printing Systems page 102 X5 Professional PCB size 508 x 508 mm* 0,2** – 6 mm PCB thickness 0,1 – 2 kg PCB weight 8 – 6*sec *(with HSP 3x508mm) Cycle time 450 x 450 – 740 x 740 Stencil frame size Alignment repeatability ± 12,5µm@6Sigma Print repeatability ± 20µm@6Sigma Weight ca.1185 - 1250kg › iROCS & iROCS Advanced › SIMPLEX user interface › 2 ½ D Plus or Super inspection › Closed loop head › Paste height detection with 3 levels › EVA ™ - EKRA vision alignment system › Vacuum option for print nest › iQUESS – intelligent squeegee exchange system › iROCS – Non stop operation › Hybrid & Optilign applications › Print repeatability 20µm@6sigma › Dual iPAG / iPAG Jet *requires a vacuum print nest for PCB 0,2 – 0,5mm ** depending on installed options

Recommend

More recommend