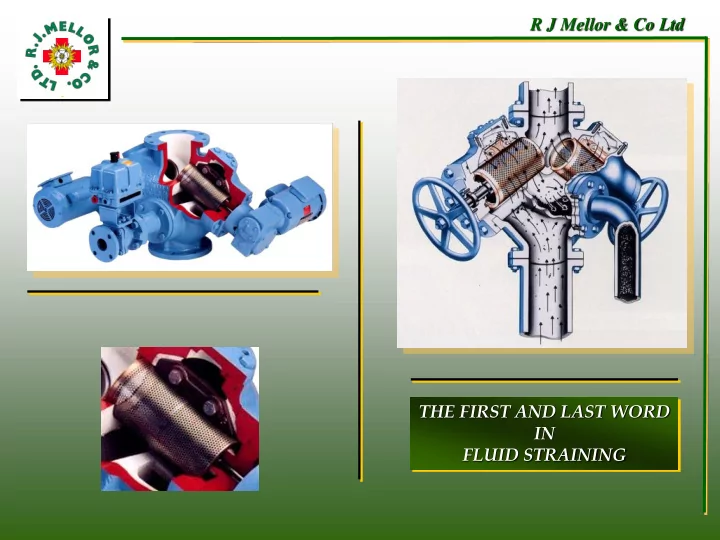

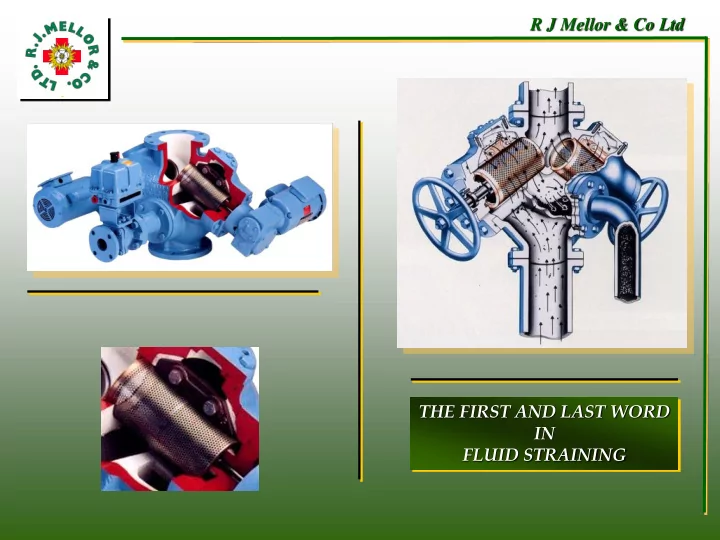

R J Mellor & Co Ltd THE FIRST AND LAST WORD IN FLUID STRAINING

R J Mellor & Co Ltd Unique Operating Features That Provide Real Benefits The Hellan Strainer design provides solids removal without interrupting the fluid flow - (eliminating downtime for solids removal). Employees are not exposed to possible contaminants and/or hazardous materials during the cleaning cycle. (No baskets to remove to clean or empty) Minimal labour required for solids removal from fluid flow. Manually operated models require less than 30 seconds per cleaning cycle. Automatically operated strainers require no labour and are controlled by timers or pressure differential switches. Depending on size and material can be 45% lighter than a conventional dual basket strainer and substantially smaller dimensionally. Up to 12” can be installed in any plane in the pipe -line without the need for additional support.

R J Mellor & Co Ltd 1) Fluid passes into the strainer and through a screen. 2) A deflection rib protects the screen from large objects. 3) The screened fluid flows out of the strainer and into service. 4) Rotating the screen, by either handwheel or motor, moves the outer screen surface against a scraper bar or brush. The scraper bar or brush removes collected debris from the screen’s outer surface. 5) Debris falls to to the sump area of the strainer where it is removed by periodic flushing. 6) Large inspection ports, sealed with O-rings, permit easy, external adjustment of the scraper bar or brush. Multiple screen models size 4” and larger, plus 3” single screen models. 7) O-rings at the screen cover plate and shaft provide a tight seal while allowing operation at low torque.

R J Mellor & Co Ltd Quality Assurance American Bureau of Underwriters Shipping Laboratories Hellan Strainers are certified for service with Non-automatic Hellan Strainers constructed of fuel oil, lube oil, fresh and sea water service by cast iron, cast or stainless steel in pipe sizes the American Bureau of Shipping. ABS has from 2" through to 14" with screen perforations rated Hellan Strainers for 150 psi (10.34 bar) of 3/32", 1/8" or 3/16" are listed with MAWP to 740 psi (51.02 bar) MAWP, Underwriters Laboratories (Re-examination depending on flange class, construction Service) and are UL listed under strainers, Pipe material and temperature of the process fluid. Line (HLCV), File EX 1708 (N),"Fire Main Line Strainer". National Fire American Society of Sprinklers Mechanical Engineers Association, Inc (ASME) Hellan Strainers are designed in accordance with ISO 9001 ASME Boiler and Pressure Vessel Code Section 8. All strainers are proof tested at 150% of their Certificate No recommended maximum allowable operating QSC-4386 pressure. Fluid Control Quality System certified by:- DET NORSKE VERITAS Institute Hellan Strainers are available in models that Hellan Strainers are manufactured in accordance with FCI comply with most international standards, standard 78-1. including D.I.N., I.E.C. and Cenlec specification.

R J Mellor & Co Ltd Selecting A Hellan Strainer Selecting the Perforation Size Hellan Fluid Strainers recommend that a screen perforation hole diameter be selected that is 40 to 60% of the diameter of the smallest orifice in the system. Selecting a smaller perforation than required leads to unnecessary cleaning cycles and higher pressure drops during operation.

R J Mellor & Co Ltd STRAINER SIZE OPTIONS Pipe Size Flow Inches mm US.g.p.m. Ltr.p.m. Sizing the Strainer 2" 50.8 80 302 2.5" 63.5 130 492 3" 76.2 200 757 4" 101.6 300 1,135 Existing Pipe Size Method 6" 152.4 750 2,839 • This method is used when a Hellan Strainer is installed in an 8" 203.2 1,250 4,731 existing network of piping. Flow rate and attendant pressure drop are within the application requirements. 10" 254 1,750 6,624 In these situations, it is common practice to select a strainer 12" 304.8 2,300 8,706 size that matches the existing pipe size, i.e. an 8" strainer would be selected for an installation with an existing 8" line. 14" 355.6 3,500 13,248 16" 406.4 4,600 17,412 20" 508 8,000 30,283 Flow Rate Requirement Verses Pressure Drop Method Flows are based on 1.5 psi clean pressure • This method should be utilized when selecting a strainer for drop with a screen perforation of 1/32". a new installation or as a replacement strainer in an existing SEE CATALOGUE FOR FURTHER system where a specific flow and pressure rate are required. INFORMATION

R J Mellor & Co Ltd Standard Perforated Metal Screen Options 1/64"STAGGERED 1/32"STAGGERED 1/8"STAGGERED 3/16"STAGGERED (0.4825 mm) 30% open (0.965 mm) 20% open (3.175 mm) 40% open (4.763 mm) 51% open 1/16"STAGGERED 3/32"STAGGERED 1/4"STAGGERED (1.588 mm) 24% open (2.381 mm) 33% open (6.350 mm) 58% open

R J Mellor & Co Ltd Standard Wedge Wire Screen Options Inches Mesh Micron 0.015 40 385 0.009 60 230 0.007 80 180 0.005 100 140 0.004 150 100 0.002 300 50 0.001 ~ 25 0.0006 ~ 15 NOTE:- Other wedge-wire slot sizes are available to special order

R J Mellor & Co Ltd STANDARD STRAINER BODY MATERIALS THREADED AND FLANGE OPTIONS Cast Iron Cast Steel St. Steel Cast Bronze Class Class Class Class Class Class Class Class STRAINER TYPE NPT NPT 250 150 300 150 300 150 300 125 1.5" In-Line Flow (1.5S) x x 2.0" Angle Flow (2A) x x x 2.0" In-Line Flow (2.S) x x x 2.5 " Angle-Flow (2.5A) x 2.5" In-Line Flow (2.5S) x x 2.5" In-Line Flow (2.5D) x 3.0" In-Line Flow (3S) x x x 3.0" Angle Flow (3A) x x x x 3.0" In-Line Flow (3D) x x x x 4.0" In-Line Flow (4D) x x x x x x x x 6.0" In-Line Flow (6D) x x x x x x x x 8.0" In-Line Flow (8D) x x x x x x x x 10" In-Line Flow (10D) x x x x x x x 12" In-Line Flow (12D) x x x x x x x

R J Mellor & Co Ltd STANDARD STRAINER BODY MATERIALS THREADED AND FLANGE OPTIONS Cast Iron Cast Steel St. Steel Bronze Class Class Class Class Class Class Class Class STRAINER TYPE 125 250 150 300 150 300 150 300 14" In-Line Flow (14SA) x 14" In-Line Flow (14Q) x 16" In-Line Flow (16SA) x 16" In-Line Flow (16Q) x 20" In-Line Flow (20WDA) 20" In-Line Flow (20H) x 24" In-Line Flow (24W3DA) 30" In-Line Flow (30WDA) 36" In-Line Flow (364DA)

R J Mellor & Co Ltd STANDARD STRAINER BODY MATERIALS AND FLANGE OPTIONS Fabricated Fabricated Carbon Steel Carbon Steel Class Class Class Class STRAINER TYPE 150 300 150 300 14" In-Line Flow (14SA) x x 14" In-Line Flow (14Q) 16" In-Line Flow (16SA) x x 16" In-Line Flow (16Q) 20" In-Line Flow (20WDA) x x 20" In-Line Flow (20H) 24" In-Line Flow (24W3DA) x x 30" In-Line Flow (30WDA) x x 36" In-Line Flow (364DA) x x

R J Mellor & Co Ltd Pressure Ratings & Flow Rates The table below provides both pressure and flow rates for standard Hellan Strainers (0.1034214 bar (1.5 psid ) with 1/8" perforated screen). Refer to catalogue for further information. Cast Iron Cast Steel Stainless Steel Bronze Class Class Class Class Class Class Class Class Flow Wgt Wgt Wgt Wgt 125 250 150 300 150 300 150 300 Strainer Type Lpm Kg Bar Bar Kg Bar Bar Kg Bar Bar Kg Bar Bar 1.5” In -Line Flow TSH 360 21 12.06 22 15.6 18.96 15.6 1.5” In -Line Flow TSA 360 46 12.06 47 15.6 18.96 15.6 2.0” In -Line Flow TSH 360 21 12.06 22 15.6 18.96 15.6 2.0” In -Line Flow TSA 360 46 12.06 47 15.6 18.96 15.6 2.0” Angled Flow AH 360 32 12.06 34 15.6 18.96 15.6 2.5” In -Line Flow TSH 606 38 12.06 40 15.6 18.96 15.6 2.5” In -Line Flow TSA 606 63 12.06 65 15.6 18.96 15.6 2.5” Angle Flow AH 606 32 12.06 34 15.6 18.96 15.6 2.5” In -Line Flow DH 606 45 12.06 48 15.6 18.96 15.6 3.0” In -Line Flow TSH 890 38 12.06 40 15.6 18.96 15.6 3.0” In -Line Flow TSA 890 63 12.06 65 15.6 18.96 15.6 3.0” Angled Flow AH 890 32 12.06 34 15.6 18.96 15.6 3.0” Angled Flow AA 890 69 12.06 74 15.6 18.96 15.6 3.0” In -Line Flow DH 890 61 12.06 66 15.6 18.96 15.6 NB.Pressure ratings shown are for a maximum temperature of 100 o F ( 37.78 o C ) for steel and stainless steel and 150 o F ( 65.56 o C ) for cast iron and bronze

Recommend

More recommend