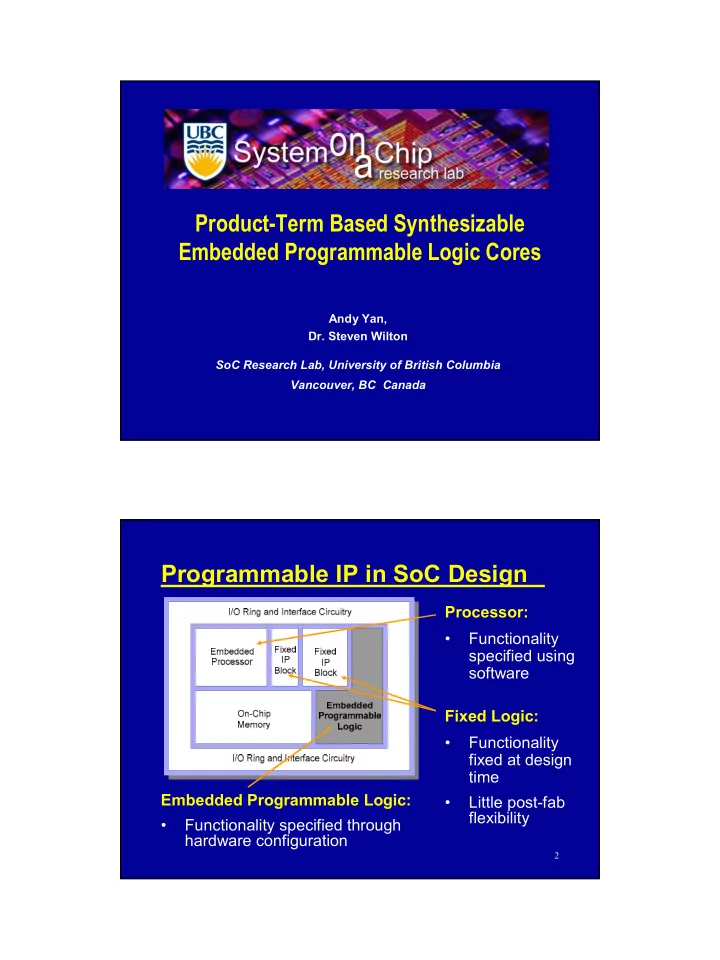

Product-Term Based Synthesizable Embedded Programmable Logic Cores Andy Yan, Dr. Steven Wilton SoC Research Lab, University of British Columbia Vancouver, BC Canada Programmable IP in SoC Design Processor: • Functionality specified using software Fixed Logic: • Functionality fixed at design time Embedded Programmable Logic: • Little post-fab flexibility • Functionality specified through hardware configuration 2 1

“Hard” Programmable IP Flow 3 Soft Programmable Logic Cores • Conventional approach – “ Hard ” FPGA layout provided by vendors • Our approach – Synthesizable Programmable Logic Core (PLC) – “ Soft ” : HDL used to describe a PLC architecture, NOT to describe a particular user circuit – Synthesis required to translate RTL to gates 4 2

Soft Programmable Logic Cores • Advantages – Easy to integrate, reduces design time – Very flexible, can create the exact required core – Easy to migrate to smaller technologies • Disadvantages – Inefficient compared to hard cores • Our thought – Makes sense if you only want a small core (a few hundred gates, perhaps) e.g. next state logic in state machine 5 “Soft” Programmable IP Flow 6 3

Our Contribution • Previous architecture design – Gradual Architecture [Kafafi et al., FPGA `03] – Basic logic element: Lookup-tables (LUT) • Propose new architectural family – Basic logic element: Product-term array block – 35% density improvement – 72% speed improvement 7 Basic Logic Elements Lookup-Table (LUT) Product-term Block (PTB) i inputs . . . p product-terms . . . . . . . . . . . . Single . . . . . . . . . . . . . . . . . . . . . . . . . . . Output . . . . . . . . . . . . k Select o outputs 8 4

Architectural Requirements • Area and delay minimization – Large capacity product-term blocks (PTB) and shallow core depth • Simple placement and routing – “ Full connectivity ” routing fabric • Flexible and scalable architecture – Architecture parameter definitions and optimizations 9 Synthesizable PTB Architecture • Product-term blocks (PTBs) arranged in several levels • Unidirectional signal flow to avoid combinational loops in un-programmed fabric • Outputs of PTBs in one level can only be connected to inputs in subsequent levels • 2 interconnect strategies: Rectangular and Triangular PTB architecture 10 5

Rectangular PTB Architecture 11 Triangular PTB Architecture 12 6

Detailed View of Interconnect Fabric PTB • Very flexible, PTB not restrictive • Easy P&R OUTPUTS INPUTS tools PTB PTB • We can do better though PTB PTB 13 Parameter Optimization Two Parameter Classes: • High-Level Parameters – Specified by SoC core user / VLSI designer – Used to identify a specific core in a programmable library • Low-Level Parameters – Not specified by SoC core user / VLSI designer – Used to describe specific characteristics of library – Determined through architectural experimentation 14 7

Architectural Parameters High-Level Low-Level Parameters Parameters Number of Inputs Number of Primary Inputs Pins per PTB (I) Number of Primary Output Number of Product-terms Pins per PTB (p) Number of Outputs Number of Product-term blocks (PTBs) per PTB (o) Ratio of PTBs in Neighboring Levels (r, α ) 15 Low-Level Parameter Optimization Rectangular PTB Architecture r = ratio of width to height 16 8

Rectangular PTB Architecture Area 1100 Area ( � m 2 x1000) 1000 900 800 700 600 0.0 0.2 0.4 0.6 0.8 1.0 r (ratio of width to height) 17 Rectangular PTB Architecture Depth 4.5 4.0 Depth of Circuit 3.5 3.0 2.5 2.0 0.0 0.2 0.4 0.6 0.8 1.0 r (ratio of width to height) 18 9

Rectangular PTB Architecture 3000 Area * Depth 2500 2000 1500 0.0 0.2 0.4 0.6 0.8 1.0 r (ratio of width to height) 19 Low-Level Parameter Optimization Triangular PTB Architecture � = 0.33 0.5 0.66 0.75 � = number of PTB drop-off factor • 19% improvement in area-delay 20 10

Other Low-Level Parameters i inputs Product-Term Block Parameters: . . . p product-terms • input i = 12 . . . . . . • product-term p = . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 or 18 depending . . . . . . on size of circuit . . . . . . • output o = 3 o outputs 21 Comparison to LUT-based Architecture • 35% area improvement, 72% delay improvement • Gains mainly from larger circuits (more than 50 equivalent 4-LUTs) • Factors: – PTB-based architecture has larger and fewer logic blocks – PTB-based architecture routing fabric simpler and depth of core shallower 22 11

Comparison to LUT-based Architecture # of PTBs 0 10 20 30 40 2500 Area ( � m 2 x1000) 2000 LUT Architecture 1500 1000 PTB Architecture 500 0 0 5 10 15 20 25 # of LUTs per side 23 Comparison to LUT-based Architecture # of PTBs 0 10 20 30 40 120 100 Delay (ns) LUT 80 Architecture 60 PTB 40 Architecture 20 0 0 5 10 15 20 25 # of LUTs per side 24 12

Summary • Presented a product-term based synthesizable programmable logic device • Investigated effects of various architectural parameters • Optimal product-term block (PTB) parameters: – input i = 10 – product-term p = 9 or 18 depending on size of circuit – output o = 3 25 Summary • Compared product-term architecture to lookup- table based device • Overall, 35% smaller and 72% faster • Primarily due to reduction in amount of circuitry needed to route signals 26 13

Recommend

More recommend