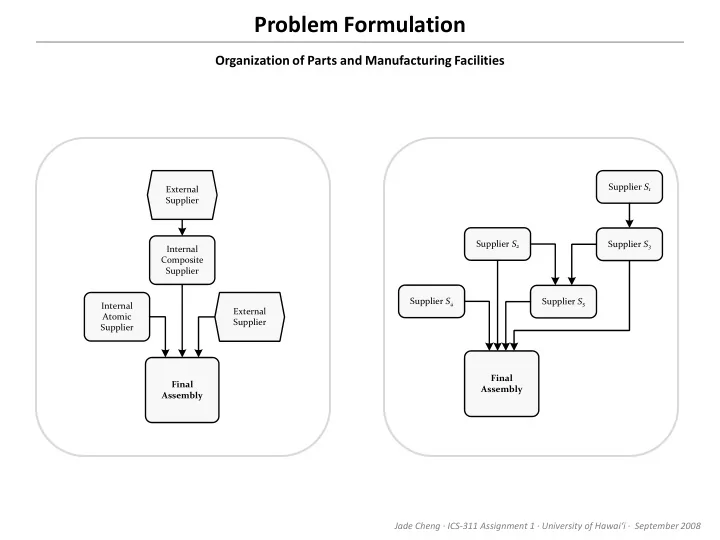

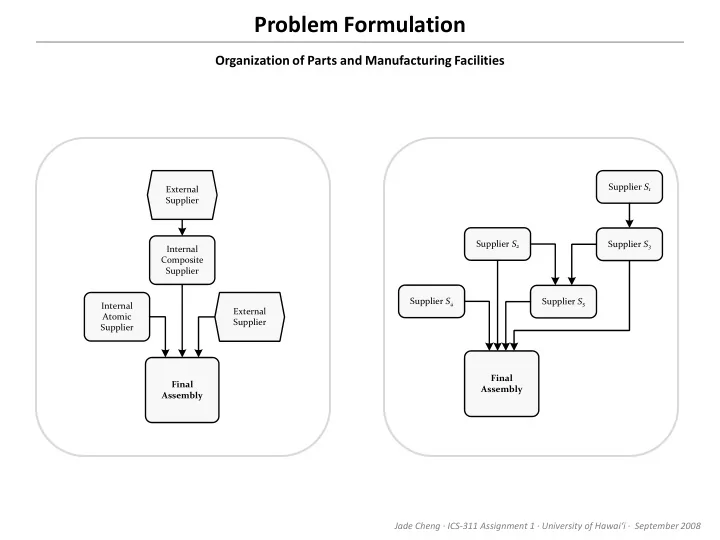

Problem Formulation Organization of Parts and Manufacturing Facilities Supplier S 1 External Supplier Supplier S 2 Supplier S 3 Internal Composite Supplier Supplier S 4 Supplier S 5 Internal External Atomic Supplier Supplier Final Final Assembly Assembly Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Configuration Setup for the Model Facilities Controlled by the Corporation Transportation Cost Location j Transportation Flow Location l x ij = 1 x kl = 1 Task i Task k Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Configuration Setup for the Model Facilities Controlled by the Corporation Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Configuration Setup for the Model Facilities Not Controlled by the Corporation Transportation Cost External Transportation Flow Location j Supplier b x ab = 1 x ij = 1 Task a Task i Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Configuration Setup for the Model Facilities Not Controlled by the Corporation Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Configuration Setup for the Model Combined Cases Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Simple Example Heuristic Values Internal Relationship of Operational Fees at Three Tasks Different Locations Internal Relationship of Cost Price for Locations Three Locations to Finish Tasks Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Simple Example Plans of Action Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Simple Example Visualization of the Model – Plan 1 Task A Location a 10 20 25 0 20 0 Task B Location b 30 15 7 40 0 35 Location c Task C Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Simple Example Visualization of the Model – Plan 4 Task A Location a 20 10 25 0 20 0 Location b 30 15 Task B 40 7 0 35 Task C Location c Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Simple Example Minimization Plan 1 Plan 4 Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Concluding Remarks An optimal solution model is built to serve as a future implementation reference for our global corporation client in order to achieve the most cost-effective manufacturing and distribution business planning. The model is constructed under a series of preliminaries . We considered most of the possible factors affecting optimization in models like our own, but we analyzed only the key conceptions and limitations in depth. The problem is formulated as a weighted bipartite graph representing facility layout and location planning for both the internal and external suppliers of the corporation. The formulas allow for optimization by minimizing sums based on the weights of the graph. Neither an algorithm nor an implementation was provided, and as such, the model is not meant to be used directly in real life. Instead it is meant to serve as a simplified model of a real-world problem. Jade Cheng · ICS-311 Assignment 1 · University of Hawai‘i · September 2008

Recommend

More recommend