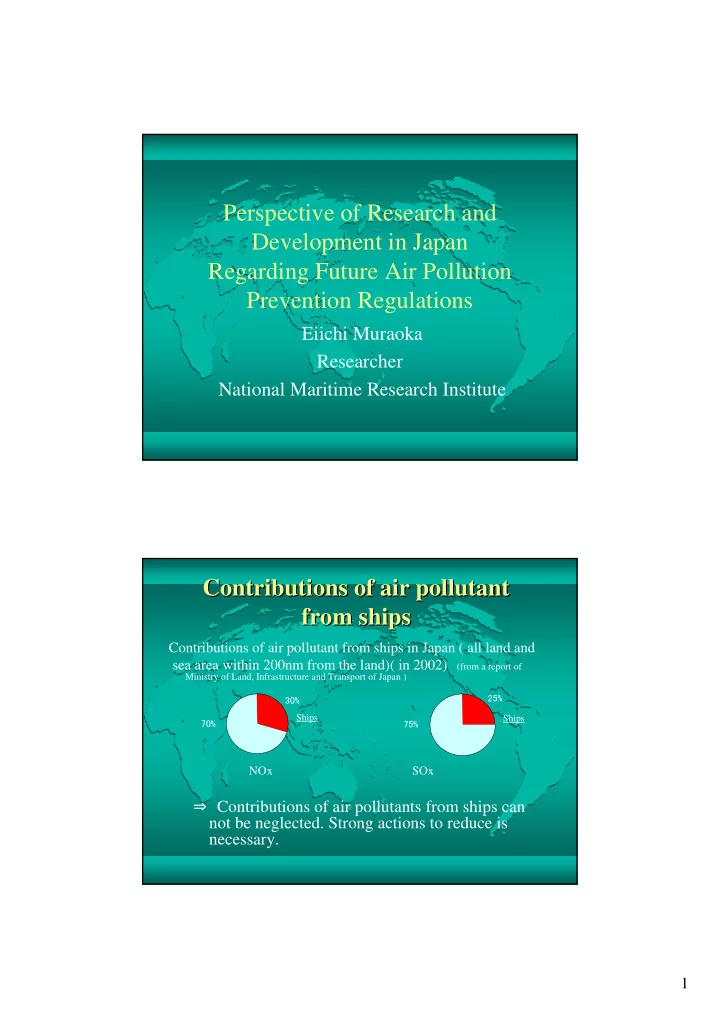

Perspective of Research and Development in Japan Regarding Future Air Pollution Prevention Regulations Eiichi Muraoka Researcher National Maritime Research Institute Contributions of air pollutant Contributions of air pollutant from ships from ships Contributions of air pollutant from ships in Japan ( all land and sea area within 200nm from the land)( in 2002) (from a report of Ministry of Land, Infrastructure and Transport of Japan ) 25% 30% Ships Ships 70% 75% NOx SOx ⇒ Contributions of air pollutants from ships can not be neglected. Strong actions to reduce is necessary. 1

Current NOx limit and considerable Current NOx limit and considerable points for future limit(1) points for future limit(1) ○ Current NOx limit of new engines for marine use NOx [g/kWh] D2/E2/E3/C1 Cycles on Marine Diesel Oil 20 n < 130rpm 17.0 g/kWh 18 - 0.2 130≦ n < 2000 rpm 45・ n g/kWh 16 n≧2000 rpm 9.8 g/kWh 14 12 10 8 6 4 2 0 0 200 400 600 800 1000 1200 1400 1600 1800 2000 2200 Engine speed [rpm] ☆ The current limit were set at 70% level of NOx of 1990 ’ s engines at 1997. → Recent progress on NOx reduction technologies are not reflected to the limit . ☆ The limit are applied to engines installed on ships constructed after 2000.Jan.1 → Pre-2000 engines are not regulated. Current NOx limit and considerable Current NOx limit and considerable points for future limit(2) points for future limit(2) ○ NOx limit of new engines for marine use 2000- n<130rpm 17.0g/kWh 130 ≦ n<2000rpm 45 ・ n -0.2 g/kWh n≦ 130rpm 9.8g/kWh ○ NOx limit of new engines for t rucks>2.5t in Japan 2003-2005 3.38g/kWh 2.0g/kWh 2005- 0.7g/kWh) (2009- ☆ Compared to limit of trucks, Limit of engines for marine use is very high at present . 2

NOx reduction rate of technologies NOx reduction rate of technologies for new engines (from an IMO report; BLG11/5) for new engines (from an IMO report; BLG11/5) ○ In Engine technologies; 10-15%(2-STROKE SLOW-SPEED) Up tp 20%(4-STROKE RESIDUAL FUEL ) 25-30%(4-STROKE DISTILLATE FUEL) ○ Water technologies, EGR and additional engine control 15-25% :Emulsification 40%: Direct Water Injection (development phase) up to 40%: Intake Air Humidification (development phase) 30-40% : EGR (early development phase) up to 50%: Additional Engine Control (Only for 4-STROKE Engines which designated to use DISTILLATE FUEL sulpher content ≦ 500ppm) ○ SCR ( Selective Catalytic Reduction ) technologies 80-85% : But Urea availability, potential anmonium slip, additional cost etc. are pointed out. Current SOx Current SOx limit and considerable limit and considerable (1) s for future limit (1) points for future limit point ○ Sulpher content limit in fuel -Global Cap : Sulpher content ≦ 4.5% -SOx Emission Control Areas (SECAs) ~ Baltic Sea and North Sea ~ ① Sulpher content ≦ 1.5% or② Fit an exhaust gas cleaning system ( EGCS) ~ Recent monitoring results of Sulpher content of residual oils ~ Average 2.67% ~ Limit of Sulpher content of distillate fuel for trucks in Japan ~ 0.05% ( 500ppm )→ 0.005% ( 50ppm ) (after the end of 2004) → 0.001%(afetr 2007 Jan. 1st) 3

Current SOx SOx limit and considerable limit and considerable Current s for future limit ( ( 2 2 ) ) point points for future limit ○ Sulphur content ☆ There are severe concerns of the sulpher content ’ s limits from the environment protection view. ☆ Supply volume of Low sulpher contained oil is limited at present. ○ EGCS ☆ There are concerns of qualities of discharge water from EGCS. Current IMO Regulations for other air Current IMO Regulations for other air pollutant substances pollutant substances ○ MARPOL Annex VI regulates NOx, SOx, Ozone depleting substances, Volatile Organic Compounds (VOCs) from cargoes and incinerator and fuel quality. But Particulate Matter(PM) is not regulated . ☆ It is generally said that reduction of NOx and SOx of emission gas can reduce volume of PM. But it is also said that proper environment impact of PM from marine engines is still uncertain because of uncertainties of generating mechanism, diffusion process and etc. And it is also said that proper measurement is technologically difficult at present. 4

Future R&D items Future R&D items for future limit(1) for future limit(1) ○ NO x Reduction technology development ① For New engines SCR is considerably the most significant reduction performance. But it has still technological difficulties. In addition, it should also need consideration for size of SCR and agent tanks and layout. To minimize their sizes, it is also important to consider further development of in-engine technologies. ⇒ It is important to develop both in-engine technologies and SCR technologies. ② For Existing engines There are no common reduction technologies for existing engines. And for applying existing ships, it is difficult to change engine room layout. ⇒ it is important to develop technologies which have sufficient reduction rate and can eliminate/minimize engine room modification. ③ Measurement method For adopting new technologies such as SCR and certifying existing engines, it is necessary to develop simple but reliable measurement method. Future R&D items for future Future R&D items for future limit(2) limit(2) ○ SO x ① Use low sulpher fuel It may need to develop facilities for refining Low sulpher fuel. And it may also consider effect of low sulphur fuel to engine performance. ② Exhaust gas cleaning system (EGCS) There are concerns of size of EGCS and quality of discharging water from EGCS. ⇒ It is necessary to develop smaller systems which still have high reduction performance with harmless discharge water. ○ PM It is necessary to establish clear definition of PM and proper method to be measured engines . And it is also necessary to find out an appropriate reduction technology to reduce PM through proper measurement. It may be achieved through tightening NOx and SOx limits. 5

R&D Project in Japan R&D Project in Japan ~“ Super Clean Marine Diesel Project ~“ Super Clean Marine Diesel Project ” ” ~ ~ ☆ ☆ The project starts in 2007 by MLIT of Japan in cooperate with re The project starts in 2007 by MLIT of Japan in cooperate with relevant levant industries, institutions etc. industries, institutions etc. ☆ ☆ NMRI set up a new project team to support the project on Febru NMRI set up a new project team to support the project on February ary 1,2007. 1,2007. R&D Project in other countries R&D Project in other countries ” I.P. HERCULES Project ” (1) ~ ~ ” I.P. HERCULES Project ” (1) ~ ~ ○ The I.P. HERCULES (Integrated Project: H igh E fficiency R &D on C ombustion with U ltra L ow E missions for S hips) is a large scale cooperative R&D project supported by the European Commission and the Swiss Federal Government (BBW & BFE). ○ The participating organizations are from 10 countries from Europe: 9 are EU Member Countries (Austria, Czech Republic, Denmark, Finland, Germany, Greece, Italy, Sweden, United Kingdom) 1 is Associated to FP6 Country (Switzerland) ○ I.P. HERCULES VISION Year 2010 Year 2020 Reduction of fuel consumption and CO2 emissions -3% -5% Reduction of NOx (Relative to IMO 2000 standard) -30% -60% Reduction of other emission components (PM, HC) -20% -40% Improvement in engine reliability +20% +40% Reduction of time to market -15% -25% Reduction in lifecycle cost -10% -20% 6

R&D Project in other countries R&D Project in other countries ~ ” ” I.P. HERCULES Project I.P. HERCULES Project ” ” (2) (2) ~ ~ ~ ○ Research and Technological Development work is structured in following 9 Workpackages, 18 Tasks and 54 Subprojects. Workpackage 1: Extreme design parameters Workpackage 2: Advanced Combustion Concept Workpackage 3: Multistage Intelligent turbocharging Workpackage 4: Turbocompound engine/hot engine Workpackage 6: Emission reduction methods (internal-water) Workpackage 7: Emission reduction methods (internal-EGR) Workpackage 8: Emissions aftertreatment Workpackage 9: Reduced friction engine Workpackage 11: Adaptive engine Thank you for your attention. 7

Recommend

More recommend