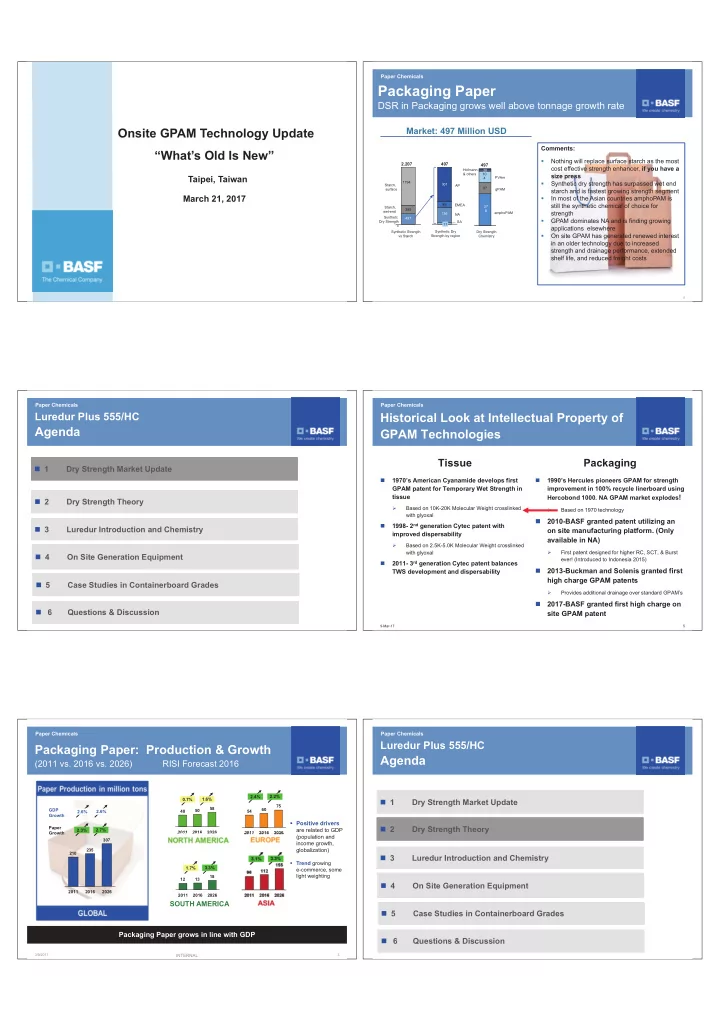

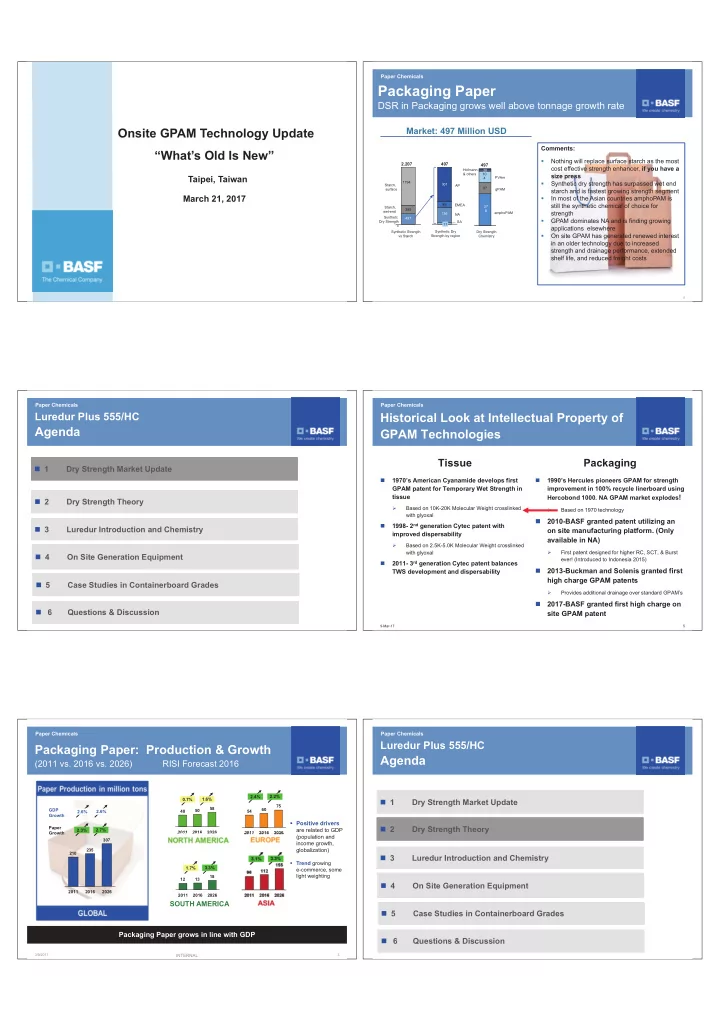

Paper Chemicals Packaging Paper DSR in Packaging grows well above tonnage growth rate Onsite GPAM Technology Update Market: 497 Million USD Comments: “What’s Old Is New” � Nothing will replace surface starch as the most 2.207 497 497 cost effective strength enhancer, if you have a Hofmann 20 & others 10 size press Taipei, Taiwan 4 PVAm � Synthetic dry strength has surpassed wet end 1794 301 Starch, AP 97 surface gPAM starch and is fastest growing strength segment March 21, 2017 � In most of the Asian countries amphoPAM is 49 EMEA still the synthetic chemical of choice for Starch, 27 385 6 wet-end strength 136 amphoPAM NA Synthetc 497 � GPAM dominates NA and is finding growing Dry Strength SA 11 c applications elsewhere Synthetic Strength Synthetic Dry Dry Strength � On site GPAM has generated renewed interest vs Starch Strength by region Chemistry in an older technology due to increased strength and drainage performance, extended shelf life, and reduced freight costs 4 Paper Chemicals Paper Chemicals Luredur Plus 555/HC Historical Look at Intellectual Property of Agenda GPAM Technologies Tissue Packaging � 1 Dry Strength Market Update � 1970’s American Cyanamide develops first � 1990’s Hercules pioneers GPAM for strength GPAM patent for Temporary Wet Strength in improvement in 100% recycle linerboard using tissue Hercobond 1000. NA GPAM market explodes ! � 2 � 2 Dry Strength Theory Dry Strength Theory � Based on 10K-20K Molecular Weight crosslinked � Based on 1970 technology with glyoxal � 2010-BASF granted patent utilizing an 1998- 2 nd generation Cytec patent with � � 3 � 3 Luredur Introduction and Chemistry Luredur Introduction and Chemistry on site manufacturing platform. (Only improved dispersability available in NA) � Based on 2.5K-5.0K Molecular Weight crosslinked with glyoxal � First patent designed for higher RC, SCT, & Burst � 4 � 4 On Site Generation Equipment On Site Generation Equipment ever! (Introduced to Indonesia 2015) 2011- 3 rd generation Cytec patent balances � � 2013-Buckman and Solenis granted first TWS development and dispersability high charge GPAM patents � 5 � 5 Case Studies in Containerboard Grades Case Studies in Containerboard Grades � Provides additional drainage over standard GPAM’s � 2017-BASF granted first high charge on � 6 � 6 Questions & Discussion Questions & Discussion site GPAM patent 9-Mar-17 5 Paper Chemicals Paper Chemicals Luredur Plus 555/HC Packaging Paper: Production & Growth Agenda (2011 vs. 2016 vs. 2026) RISI Forecast 2016 2.4% 2.2% 0.7% 1.6% � 1 � 1 Dry Strength Market Update Dry Strength Market Update 75 58 GDP 60 2.6% 2.6% 48 50 54 Growth � Positive drivers � 2 Dry Strength Theory Paper 2.7% are related to GDP 2.3% 2011 2016 2026 Growth 2011 2016 2026 (population and 307 income growth, 235 globalization) 210 � 3 � 3 Luredur Introduction and Chemistry Luredur Introduction and Chemistry 3.3% 3.1% � Trend growing 155 1.7% 3.3% e-commerce, some 112 96 light weighting 18 12 13 � 4 � 4 On Site Generation Equipment On Site Generation Equipment 2011 2016 2026 2011 2016 2026 2011 2016 2026 SOUTH AMERICA � 5 � 5 Case Studies in Containerboard Grades Case Studies in Containerboard Grades Packaging Paper grows in line with GDP � 6 � 6 Questions & Discussion Questions & Discussion 3/9/2017 INTERNAL 3

Paper Chemicals Paper Chemicals Fiber Contact Area Technology Overview Optimal Contact Area Luredur Plus 555/HC is… A cellulose reactive cationic dry strength resin Chemically modified at customer site for optimal performance Bonded Area Most effective pure strength additive available BASF patent protected technology Practical Contact Area 9-Mar-17 10 Paper Chemicals Paper Chemicals Chemical bonds – associated strength Technology Overview � HYDROGEN BONDING Luredur Plus 555/HC does… � 4-6 kcal/mole � Cellulose, Starch, Mechanical Formation Aids Increase SCT, Burst, Concora, Tensile, and Ply Bond of paper and board � IONIC BONDING Raise productivity via faster wet end water removal and light-weighting � 10-30 kcal/mole � Dual Polymer Systems, Amphoteric Copolymers Provide a linear strength response to very high contribution level � COVALENT BONDING Deliver a very high return on investment � 60-80 kcal/mole � PAE Wet Strength Resins, Glyoxalated Polyacrylamide (g-PAM) 9-Mar-17 11 Paper Chemicals Paper Chemicals Luredur Plus 555/HC Application Performance Agenda Typical Containerboard High Strength Specialty � 1 � 1 Dry Strength Market Update Dry Strength Market Update Physical Test 1 – 3 kg 3 – 6 kg � 2 Dry Strength Theory SCT / Ring Crush (%) + 5 – 15 +15 – 35 � 3 Luredur Introduction and Chemistry Burst (%) + 8 – 15 + 15 – 40 + 12 – 25 Tensile (%) + 5 – 12 � 4 � 4 On Site Generation Equipment On Site Generation Equipment +10 – 25 + 25 – 40 CMT (Concora) (%) � 5 � 5 Case Studies in Containerboard Grades Case Studies in Containerboard Grades Productivity Gain (%) + 4 – 10 + 8 to 15 Weight Reduction (%) - 4 to 8 N/A � 6 � 6 Questions & Discussion Questions & Discussion 9-Mar-17 12

Paper Chemicals Paper Chemicals On-site Generation Overview Mechanism of Strength Development Luredur Structure Liquid Glyoxal cPAM 40% active Turbidity 30% active Cationic, cross-linked, cellulose reactive PAM Base g-PAM Luredur forms covalent bonds with cellulose fiber make-down Acid 2% active Finished Product Fresh Water Bulk Storage 9-Mar-17 13 Paper Chemicals Paper Chemicals Generator Control Skid Comparison to Competitive g-PAMs Feature Delivered g-PAMs BASF g-PAM Mw of Base cPAM 10 – 15K 10-20 times greater Polymer bound aldehyde 1.0 1.98 Delivered Active Content 8 to 12% 30% (cPAM), 40% (glyoxal) Shelf Life in Summer 2 to 3 weeks 3 months PLC controlled with touch screen HMI and remote monitoring capability Dim: 2.44m L x 2.21m H x 1.40m W Luredur process facilitates: Building a more effective molecule Ease of use for the customer More secure supply to customer 17 Paper Chemicals Paper Chemicals Luredur Plus 555/HC Mix Tank Agenda Dimensions � 1 Dry Strength Market Update � 2 Dry Strength Theory � 3 Luredur Introduction and Chemistry Note: Measurements are to the base of the adjustable pads. � 4 On Site Generation Equipment 108” 128” 144” (275 cm) (325 cm) (365 cm) � 5 Case Studies in Containerboard Grades 8” � 6 Questions & Discussion 89” 18

Paper Chemicals Paper Chemicals Luredur Plus 555/HC Turbidity Meter and Eductors Agenda Turbidity Meter � 1 Dry Strength Market Update Light detector Light source � 2 Dry Strength Theory Sample tube Eductors � 3 Luredur Introduction and Chemistry Overflow � 4 On Site Generation Equipment line Fill line � 5 Case Studies in Containerboard Grades Drain line Caustic Acid eductor � 6 Questions & Discussion eductor 19 Paper Chemicals Paper Chemicals Luredur Plus 555/HC Case Studies Pumps CPAM Glyoxal � Results of Luredur applications in: Diaphragm pump used to pump � High Performance Linerboard viscous fluids, reliability, ease of maintenance, and familiarity � High Performance Medium Transfer/Recir. � Assumptions for Value Calculations � Incremental productivity is valued at $250 USD per ton Goulds centrifugal pump � Fiber savings is valued at $150 USD per ton 9-Mar-17 Confidential 23 Paper Chemicals Paper Chemicals Linerboard / Medium pH Probes North America Overview Objectives on 171g Liner Grades: Liner & medium 1. Reduce dry strength additive cost/T Furnish: Recycled; 75% PCW / 25% OCC 2. Lower basis weight pH probes Ash: 11-15% - from waste paper 3. Increase productivity Buffer lines pH: Neutral BASF Approach Retractable Production: 370K TPY Pneumatic lines housing Basis weight: 112 – 195 g/m² 1. Addition of 3 kg/T Luredur Plus 555 PM: 2 ply gap former, ENP 2. Remove competitive g-PAM Surface: Size press PM V : 750 - 980 m/min Results Wet-End before Luredur 1. Lower basis weight from 178 to 171g/m2 (4%) 2. Raise PM speed from 860 to 895 m/min (4%) Retention Dry cPAM – 0.5 kg/T 3. $12/T savings on dry strength Dry Strength: Competitive g-PAM – 6 kg/T 4. Medium produced with single sided size press 30 – 40 kg/T pearl starch at size press Buffer pump – Automatically provides 10 pH buffer to calibrate Customer Benefit probes at 0.3 differential Net Value: $16/T (added production and fiber savings) $15 - 20/T (estimated DSR savings) 24

Recommend

More recommend