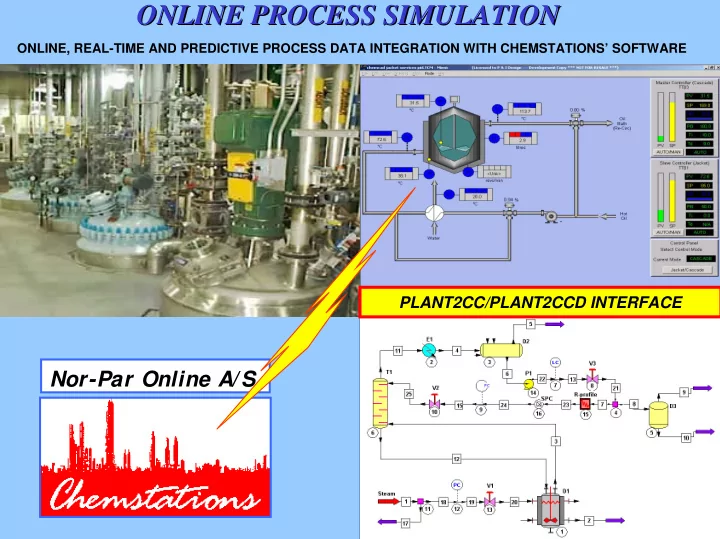

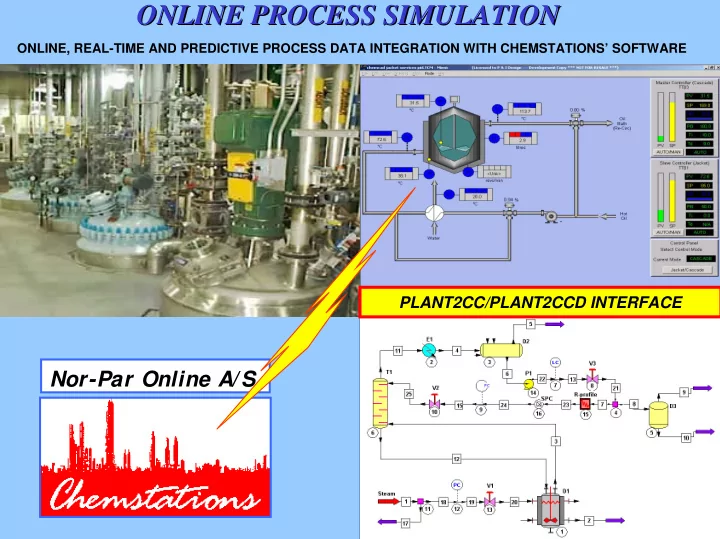

ONLINE PROCESS SIMULATION ONLINE PROCESS SIMULATION ONLINE, REAL-TIME AND PREDICTIVE PROCESS DATA INTEGRATION WITH CHEMSTATIONS’ SOFTWARE PLANT2C C/PLANT2CCD INTERFACE Nor-Par Online A/S 1

All the terms below mean exactly the same thing • SCADA = Supervisory Control And Data Acquisition • HMI = Human-Machine Interface • Process Visualization software • DCS console software • Real Time Database (RTDB) SCADA/HMI/Visualization/DCS console/RTDB is a class of software that presents data available at DCS (Distributed Control System) or PLC (Programmable Logic Controller) in a form that a human can understand. The plant personnel can also manipulate the settings of DCS/PLC directly from such SCADA systems, as a modern alternative to a traditional control room. 2

Samples of SCADA systems Modern SCADA systems are all Windows-based, run on a PC, and are compatible with Microsoft Excel. Independent SCADA DCS vendor SCADA Intellution FiX Honeywell PHD, FiX Oil Systems PI Foxboro IA Series Inc. Wonderware InTouch Omron SCS AspenTech Aspen Process Siemens Simatic WinCC Explorer US Data Factory Link Rockwell RS View 3

Online, Real-Time and Predictive Process Simulation from Nor-Par Online A/S • PLANT2CC runs online process simulation driven by true production data in CHEMCAD • PLANT2CCD runs real-time and predictive process simulation driven by true production data in CC-ReACS and/or CC-DCOLUMN • You need to have a SCADA/HMI/Process Visualization/DCS console/RTDB software compatible with Excel as well as respective Chemstations’ software to use the PLANT2CC/PLANT2CCD solution 4

What SCADA (or) HMI (or) Visualization (or) DCS Console (or) Real-Time Database does your Plant use? Before we continue, let’s have this matter clear ☺

SCADA/HMI/VISUALIZATION /HMI/VISUALIZATION SYSTEM STRUCTURE SYSTEM STRUCTURE SCADA OPERATOR WORKSTATIONS PLANT INFORMATION MANAGEMENT SYSTEMS PIMS CLIENT PROCESS CLIENT MODEL ETHERNET DATA HIGHWAY DATA DATA SERVER SERVER FIELDBUS OPC SERVERS PLC’S DCS CONTROLLER CONTROLLER CONTROLLER HARDWARE HARDWARE HARDWARE FIELD FIELD FIELD DEVICES DEVICES DEVICES 6 VALVES & SENSORS

OFFLINE DATA HANDLING OFFLINE DATA HANDLING HOW DO YOU DO IT? HOW DO YOU DO IT? SCADA/HMI/ /HMI/ SCADA ! ! ! ! ANALYSIS DECISION ANALYSIS DECISION VISUALIZATION VISUALIZATION DATA OVERLOAD INADEQUATE UNCERTAINTY TIME!!!! FLIES!!!! TIME!!!! FLIES!!!! 7

CHEMCAD CHEMCAD The Process Simulation Engine The Process Simulation Engine • Process models (flowsheets) are built and solved in a process simulator . The process simulator works as a mathematical engine for solving mass and heat balances, fluid property and equipment parameter calculations, as well as equipment sizing • We support the superior process simulation software from Chemstations Inc , which is powerful, easy to use, and has the most modern integration capabilities • CHEMCAD is Steady State process simulator. CC-ReACS, CC-DCOLUMN and CC-POLYMER are Dynamic process simulators 8

SOFTWARE STRUCTURE SOFTWARE STRUCTURE Client’s Client’s SCADA SCADA System System ReACS ** ** CC- -ReACS CHEMCAD ** ** CC CHEMCAD Batch Reactors Batch Reactors Steady State * PLANT2CC * PLANT2CC PLANT2CCD * * PLANT2CCD POLYMER ** ** DCOLUMN ** ** CC- CC -POLYMER CC- CC -DCOLUMN Polymer Reactors Dynamic Column *) From Nor-Par Online A/S **) From Chemstations Inc. 9

PLANT2CC 2CC(D) (D) SYSTEM ARCHITECTURE SYSTEM ARCHITECTURE PLANT SCADA THE PC STEADY STATE PROCESS MODEL: CHEMCAD CLIENT PLANT2CC ETHER NET DATA SERVER DYNAMIC PROCESS MODEL: CC-REACS, CC-DCOLUMN Heat Transfer Oil 4 CONTR- 5 Return 2 9 8 OLLER 7 TC T 49 3 W 13696 11 5 6 TC 10 PLANT2CCD 1 T 49 15 W 45000 T 138 W 45000 T 49 W 31304 17 8 12 10 13 6 Heat Transfer Oil 7 Supply 18 13 4 3 12 FIELD 2 1 T 138 W 0 T 300 16 DEVICES T 138 W 13697 W 45000 T 138 Coolant W 45000 11 NOR-PAR ONLINE A/S CUSTOMER 10

ONLINE STEADY STATE PROCESS ONLINE STEADY STATE PROCESS OPTIMIZER OPTIMIZER C SCADA VISUALIZATION MIMIC U PROCESS S T PLANT O ! " ! " M E R S SCADA C A SYSTEM D A ! " N PLANT2CC AND CHEMCAD ! " O R P A R PLANT2CC O N ! " ! " L I N CHEMCAD E A MODEL / S 11

STEADY STATE OR DYNAMICS STEADY STATE OR DYNAMICS Steady State SCADA integration Dynamic SCADA integration " Based on Online Process Simulation " Based on Real Time or Predictive Dynamic Process Simulation principle principle, modeling the plant behavior by continuous series of steady state " Takes into account true dynamic approximations behavior of the plant, including equipment size, accumulation, and " Requires least effort to construct and control system unit operations calibrate the flowsheet " Ideal for troubleshooting, control loop " Ideal for economic analysis and online tuning and real time optimization optimization " Requires CC-ReACS or " Requires CHEMCAD only CC-DCOLUMN " Can only be applied to process units between intermediate and storage tanks 12

ONLINE DYNAMIC PRODUCTION OPTIMIZER ONLINE DYNAMIC PRODUCTION OPTIMIZER SCADA VISUALIZATION MIMIC C PROCESS PLANT U S ! " T ! " O M E R SCADA SYSTEM S C ! " ! " A D A PLANT2CCD N O DYNAMIC PROCESS MODEL R PLANT2CCD P A Heat Transfer Oil 4 5 Return 2 9 8 R 7 TC T 49 3 W 13696 11 ! " ! " 5 O 6 TC 10 1 T 49 N 15 W 45000 T 138 W 45000 L T 49 W 31304 17 I 8 12 10 13 6 Heat Transfer Oil 7 N 3 Supply 18 13 12 4 CC-ReACS 2 1 T 138 E W 0 T 300 16 T 138 W 13697 W 45000 T 138 Coolant A W 45000 CC-DCOLUMN CC-REACS, 11 / CC-DCOLUMN S 13

TRAINING & EDUCATION & EDUCATION SIMULATOR SIMULATOR TRAINING TRAINING SIMULATOR CUSTOM MIMIC OFFLINE PLANT N SCADA O R MIMIC P A ! " ! " R O N T & E Simulator L I Controller N E T & E Simulator Controller/Scenario Database Scenario Database A DYNAMIC PROCESS MODEL / ! " ! " S 4 Heat Transfer Oil D 5 Return 2 8 9 E 7 TC T 49 3 W 13696 11 A 5 6 TC 10 1 L T 49 CC-ReACS 15 W 45000 T 138 E W 45000 T 49 W 31304 R CC-DCOLUMN 17 8 12 10 S 6 13 7 Heat Transfer Oil 3 Supply 18 13 12 4 2 1 T 138 W 0 T 300 16 T 138 W 13697 W 45000 T 138 Coolant W 45000 VIRTUAL CC-REACS, 11 CC-DCOLUMN PLANT 14

ONLINE SIMULATION BENEFITS ONLINE SIMULATION BENEFITS INTEGRATED PRODUCTION SOLUTION INTEGRATED PRODUCTION SOLUTION MONITORING OPERATIONS DATABASE MAINTENANCE ECONOMIC Integration with client’s TRAINING own Production Management System HISTORY like SAP 15

MONITORING BENEFITS MONITORING BENEFITS CHEMCAD “Virtual Plant” Soft sensor (no instrument installed or available) PROCESS Component composition prediction MODEL Prediction of inferred measurements Estimation of unmeasured process conditions INTERFACE Component concentrations in reactor PLANT2CC Temperature profiles in reactors and columns Concentration profiles in the columns SCADA SYSTEM Heat transfer coefficients,fouling,specific heat Study interactions of dependent variables Estimation of physical properties PROCESS PLANT All calculated stream properties in CHEMCAD can be returned to Excel for analysis 16

OPERATIONAL BENEFITS OPERATIONAL BENEFITS Allows calibration of process model CHEMCAD “Virtual Plant” Using true data from the production PROCESS Calibration of process and control models MODEL Aids prediction of optimum performance Tool for speeding up troubleshooting INTERFACE PLANT2CC Predict the onset of production problems Identify problems from SCADA and model history Learn to start up and shut down the plant for increased safety SCADA SYSTEM Provide help for improving the process model Model inaccuracy easier to detect and correct PROCESS Online optimization based on true data PLANT Cost savings Historical data 17

MAINTENANCE BENEFITS MAINTENANCE BENEFITS CHEMCAD “Virtual Plant” Fault diagnosis & Data reconciliation PROCESS Fouling and scaling monitoring MODEL Condition monitoring of expensive equipment Instrument fault diagnosis Instrument calibration frequency INTERFACE PLANT2CC Maintenance planning Use of historical data for process and SCADA mechanical maitenance planning, integrated SYSTEM with SAP or other Process Information Management Systems PROCESS PLANT 18

TRAINING & EDUCATION & EDUCATION BENEFITS BENEFITS TRAINING Improve production efficiency SCADA SCADA operator interface is identical to real plant model Mimic Engineers understanding of the process enhanced Engineers can study effect of control settings Engineers can study parameter interactions T & E S Controller Scenario Database Downtime due to operator error reduced Learning start-up and shutdown procedures Consequences of operator actions to environment (Environmental Impact factors by WAR technology) PROCESS MODEL Improve production safety CC-ReACS Operational plant safety improved CC-DCOLUMN “Virtual Plant” Learning without the consequences of risk/damage 19

Recommend

More recommend