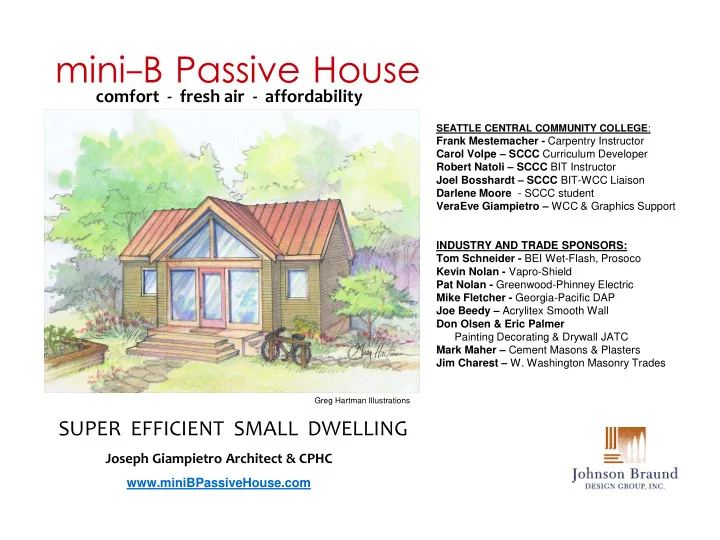

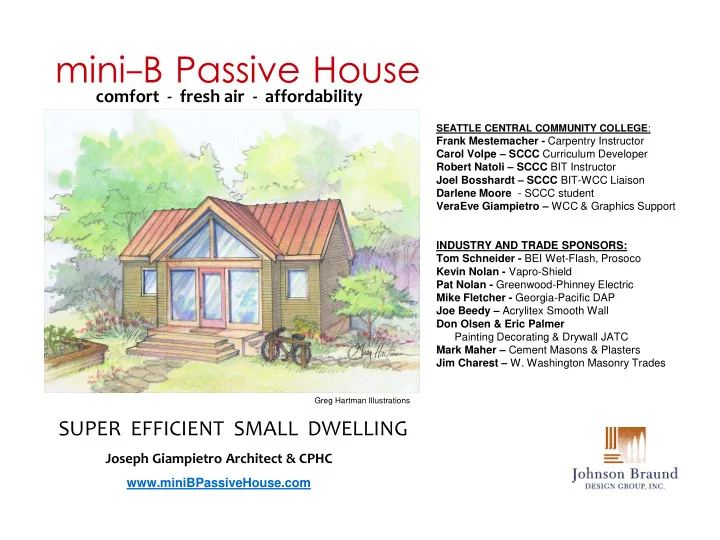

mini-B Passive House comfort - fresh air - affordability SEATTLE CENTRAL COMMUNITY COLLEGE : Frank Mestemacher - Carpentry Instructor Carol Volpe – SCCC Curriculum Developer Robert Natoli – SCCC BIT Instructor Joel Bosshardt – SCCC BIT-WCC Liaison Darlene Moore - SCCC student VeraEve Giampietro – WCC & Graphics Support INDUSTRY AND TRADE SPONSORS: Tom Schneider - BEI Wet-Flash, Prosoco Kevin Nolan - Vapro-Shield Pat Nolan - Greenwood-Phinney Electric Mike Fletcher - Georgia-Pacific DAP Joe Beedy – Acrylitex Smooth Wall Don Olsen & Eric Palmer Painting Decorating & Drywall JATC Mark Maher – Cement Masons & Plasters Jim Charest – W. Washington Masonry Trades Greg Hartman Illustrations SUPER EFFICIENT SMALL DWELLING Joseph Giampietro Architect & CPHC www.miniBPassiveHouse.com

Outline 1. Design Concept – Why a PH – DADU? 2. Passive House Challenges 3. Construction Process 4. Tested Results / Projected Energy Use 5. Lessons Learned – What works, or not 6. What next?

1. Design Concept Drawings COMFORT Temperature -- Radiation – Air Movement FRESH AIR Clean – Filtered – Draft Free AFFORDABILITY First Cost – Life Cycle Cost -- Sustainable Demonstrating Simple & Affordable Passive House (living in a warmer climate zone)

Design Intent of Interior Bed Loft - Kitchenette - ¾ Bath - 12 x 16 Living Area

Passive House Standard 1. Heat Loss Demand = 4.75 kBTU/sf-yr 4. Thermal Bridge Free Construction (calculate negative & positive bridges) “HEAT WITH A HAIR DRYER” 2. Primary Energy = 38.00 kBTU/sf-yr 5. Triple-Pane Glazing (recommended) 3. AIR TIGHT 6. HRV/ERV Efficiency = 75%+ Blower Door Test = 0.60 ACH50 (Heat/Energy Recovery Ventilation)

2. PH Challenges 1. Envelope to Floor Area Ratio of 5.7:1 = High Heat Loss 2. Lots of penetrations relative to Floor Area = More Infiltration 3. Primary Energy Use – all the functions of a larger home

Maxing Out the Options 1. Windows focused on south elevation – 43% of floor area 2. Thermal mass in concrete topping slab & 5/8 in GWB 3. Summer Shading to limit overheating 4. Evaluate Thermal Bridges of Intersections 5. Solar Hot Water Evacuated Tubes for Domestic Hot Water 6. No dishwasher – No Washer – No Dryer

Thermal Bridge Inputs Thermal Subtrac- User tion Input of Y Deter- User- Thermal Length l Group # Qty mined Determin Bridge [BTU/(hr. Bridges [ft] Length ed Heat Loss ft.F)] [ft] Length Coefficient [ft] 90deg wall 90deg wall corner 21 4 7.40 -0.050 1 29.60 corner exterior exterior Roof Eave at 21 1 38.00 -0.011 2 38.00 Wall Roof Eave at Wall Roof at Gable 21 4 8.00 -0.050 3 32.00 End Roof at Gable End Roof at Ridge 21 1 31.00 -0.026 Roof at Ridge 4 31.00 Perimeter at 22 2 36.00 -0.033 5 72.00 Ground Perimeter at Ground 6 7 8 Therm Results for 2D Assembly Therm Results for Combined 1D Assemblies Resulting Psi 2D model 1D model A 1D model B Psi U L dT ULdT error U L dT ULdT error U L dT ULdT error PsidT dT Psi (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f) (K) (Btu/h-f-F) 90 degree corner at Mini-B 0.0202 5.75 36 4.1814 3.81 0.0208 4 36 2.9952 0.8 0.0208 4 36 2.9952 0 -1.809 36 -0.05025 Ridge of Roof 0.0232 6.089 36 5.085533 5.34 0.0193 4.348 36 3.0209904 2.04 0.0193 4.348 36 3.02099 2.04 -0.95645 36 -0.02657 Eave at Roof/Wall 0.0222 6.946 36 5.551243 3.31 0.0205 4 36 2.952 0.1 0.0208 4 36 2.9952 0.84 -0.39596 36 -0.011 Perimeter at Ground 0.0168 6.896 36 4.170701 9.9 0.0205 5.896 36 4.351248 0.61 0.0146 3.875 18 1.01835 4.76 -1.1989 36 -0.0333 6 in wall glazing Light Shelf above Door 0.0481 6.156 36 10.65973 8.15 0.0189 0.5625 36 0.382725 6.01524 -0.17092 36 -0.00475 na 0.11 1.519 36 na 0.3 0.333 36 3.5964 36 0.83628 and big windows na 0.023 1.01 can be ignored wind frame spacer

Floor Portion of Perimeter Condition

Wall Portion of Perimeter Condition

Two D Therm Analysis – 0.033 BTU/hr.ft.F

Temperature Gradient at Perimeter

Wall Corner – 1 D Therm Result

Wall Corner – 2 D Result – 0.050 BTU/hr.ft.F

Wall Corner – Temperature Gradient

Wall Corner – Energy Flow – 0.050 BTU/hr.ft.F

Wall/Roof – Energy Flow – 0.011 BTU/hr.ft.F

Roof Ridge – Energy Flow – 0.026 BTU/hr.ft.F

Roof Ridge – Temperature Gradient

Light Shelf – 2D Analysis +0.00475 BTU/hr.sf.F

Thermal Bridge Inputs Thermal Subtrac- User tion Input of Y Deter- User- Thermal Length l Group # Qty mined Determin Bridge [BTU/(hr. Bridges [ft] Length ed Heat Loss ft.F)] [ft] Length Coefficient [ft] 90deg wall 90deg wall corner 21 4 7.40 -0.050 1 29.60 corner exterior exterior Roof Eave at 21 1 38.00 -0.011 2 38.00 Wall Roof Eave at Wall Roof at Gable 21 4 8.00 -0.050 3 32.00 End Roof at Gable End Roof at Ridge 21 1 31.00 -0.026 Roof at Ridge 4 31.00 Perimeter at 22 2 36.00 -0.033 5 72.00 Ground Perimeter at Ground 6 7 8 Therm Results for 2D Assembly Therm Results for Combined 1D Assemblies Resulting Psi 2D model 1D model A 1D model B Psi U L dT ULdT error U L dT ULdT error U L dT ULdT error PsidT dT Psi (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f2F) (f) (F) (Btu/h-f) (%) (Btu/h-f) (K) (Btu/h-f-F) 90 degree corner at Mini-B 0.0202 5.75 36 4.1814 3.81 0.0208 4 36 2.9952 0.8 0.0208 4 36 2.9952 0 -1.809 36 -0.05025 Ridge of Roof 0.0232 6.089 36 5.085533 5.34 0.0193 4.348 36 3.0209904 2.04 0.0193 4.348 36 3.02099 2.04 -0.95645 36 -0.02657 Eave at Roof/Wall 0.0222 6.946 36 5.551243 3.31 0.0205 4 36 2.952 0.1 0.0208 4 36 2.9952 0.84 -0.39596 36 -0.011 Perimeter at Ground 0.0168 6.896 36 4.170701 9.9 0.0205 5.896 36 4.351248 0.61 0.0146 3.875 18 1.01835 4.76 -1.1989 36 -0.0333 6 in wall glazing Light Shelf above Door 0.0481 6.156 36 10.65973 8.15 0.0189 0.5625 36 0.382725 6.01524 -0.17092 36 -0.00475 na 0.11 1.519 36 na 0.3 0.333 36 3.5964 36 0.83628 and big windows na 0.023 1.01 can be ignored wind frame spacer

3. Construction Team WCC - Seattle Central Community College Frank Mestemacher Carpentry Instructor South Seattle Community College Georgetown Campus In Association with the SCCC Business Information Technology Department – Robert Natoli Instructor

BEI Training for R-Guard Installation

BEI Joint/Seam Filler at window joint

Cat-5 Wall Treatment at Window

Cat-5 Wall Treatment at North Wall

Floor Framing in place

Walls up – ready for Roof

BEI - Prosoco - Envelope Air Tight Layer – 0.60ACH50 Will STUDENTS pass the test? R-Guard / Wet-Flash Products Fast Flash – window wrap Joint/Seam Filler – cracks/joints Cat-5 - Weather Resistive Barrier Air Dam – window caulking 1 - VAPOR PERMEABLE 2 - SELF - HEALING 3 - AIR BARRIER Seals pipe & electrical penetrations Exterior sheathed & weather sealed

Window Install with Air Dam

EPS continuous exterior insulation

Closing in the “Beer Cooler”

Vapro-Shield over EPS Insulation “Slope Shield” on the Roof “Wall Shield” on Walls Sheds Water Vapor Permeable Serious 925 Windows U-11 Glazing U-18 Assembly 1x4 Cedar Furring Straps (secured with 12 SIPS screws)

Summer Siding (& Roofing) Crew Hardie Panel 12-inch Exposure Over Vented Rain Screen Air Gap 5/4 by 10 Cedar Trim Champion Standing Seam Metal Roofing (over 1x4 furring)

Summer crew enjoying the view

Insulation & Drywall Finish Continuous Ext. Insulation equals No Thermal Bridging Paperless Drywall by GP equals No Mold Potential (on GWB) Inside GP paperless drywall completes the Insulation Sandwich = R-53 3.5-inches of Blown-in Fiberglass & 9-inches of EPS foam

Plumbing & Electrical in stud walls

With Blown-in-Blankets

w/ Wall Board & floor prepped for concrete topping

Crew ready the Blower Door test

Is the door well sealed?

16 cfm = 0.38 ACH50

4. Design Energy Use / Tested Results 2009 WA Energy Code . Mini-B Passive House . Roof R-38 Roof R-53 Walls R-21 Walls R-53 Floor R-30 Floor R-74 Windows U-0.30 Windows U-0.18 Airtightness 5.25 ACH50 . Airtightness 0.60 ACH50 . Total Heat Demand / Year = 10,320 kBTU Total Heat Demand / Year = 1,256 kBTU at Seattle City Light rate = $ 240.00 at Seattle City Light rate = $ 30.00 “HEAT WITH A HAIR DRYER” COMFORT FRESH AIR LONG TERM AFFORDABILITY Blower Door Test #1 0.58 ACH50 (at framing stage) 0.38 ACH50 (finished) Blower Door Test #2

Recommend

More recommend