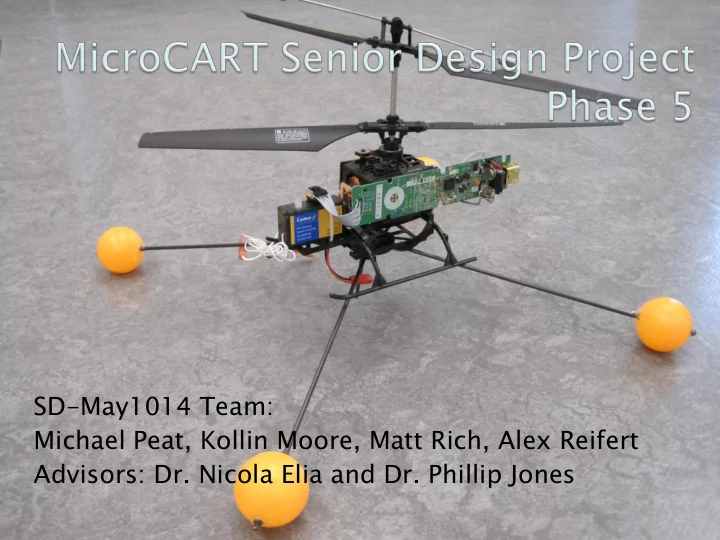

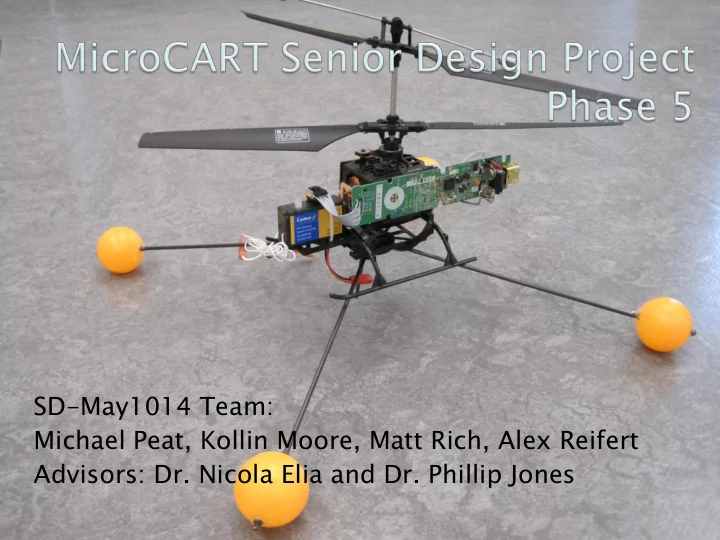

SD-May1014 Team: Michael Peat, Kollin Moore, Matt Rich, Alex Reifert Advisors: Dr. Nicola Elia and Dr. Phillip Jones

Problem: ◦ To create a small electrically powered autonomous flying vehicle capable of takeoff and landing from horizontal surfaces as well as stable indoor hover without human assistance. Ideally this should include onboard sensors for orientation and acceleration along all three rotational axes as well as altitude and overall position relative to known reference points. Solution: ◦ In order to achieve our goal, we researched platforms fitting of the above outlined description. ◦ We also researched the most light weight sensors available to us and cut out any that we did not absolutely need for basic takeoff, hover, and landing. ◦ Once a platform was firmly established and tested for capabilities we researched and attempted to create mathematical/computer simulation models for it in order to aid us in the process of designing our control system. ◦ We also established effective and reliable Bluetooth and RF communication with a computer ground station for overall flight instructions.

The operating environment for our system will be climate controlled university buildings without any obstacles (dynamic or otherwise) in the intended flight path. The vehicle shall have enough room to takeoff, hover, and land without any probable danger of collision with its surroundings. Environment will be constrained by the camera limitations of the sensor system seen below.

The base platform we are using were to malfunction and become unusable. When we are trying to write software for our control system we do not have the necessary programming knowledge to complete it. The project is too large for the time constraints we were given. Lack of funds to purchase necessary parts. Due to the complexity of the electronics and other systems that are needed for this project, some necessary components may be unavailable. Since we will be using different parts from different manufacturers, they may not be compatible for some reason and we will not be able to integrate them.

Mechanical Constraint: ◦ Our vehicle is small enough to operate indoors ◦ Our vehicle is able to carry all of the necessary sensors stably Power Constraint: ◦ Our vehicle has a limited power supply for flight in the form of a battery ◦ This power supply is carried within the platform during flight ◦ This power supply allows at least five minutes of stable flight with all equipment attached ◦ This power supply is limited in capacity due to weight considerations

Capability of autonomous takeoff, flight, and landing Capability of making high frequency mid- flight stability adjustments Capability of communicating with computer ground station

Carnegie Mellon Georgia Tech 2009 Embry Riddle College of University Aerial Robotics Team Engineering Technische Universitaet Massachusetts Institute Berlin South Dakota School of Mines of Technology and Technology (SERV Robot)

Innovision Tracking Systems MaxTRAQBasic 3D System ◦ Either 60 Hz or 120 Hz ◦ $5000 to $5500 MaxPRO Upgraded Motion Capture Software ◦ Can reach 250 Hz ◦ $9000 -$28000 WorldVizPPT Very Precise and Fast ◦ Has option of additional sensors that measure roll pitch and yaw ◦ $10000 -$30000

Helicopter WII Remote Flight • IR Camera Controls • Accelerometer • Bluetooth Transmitter IR LED Power Converter Constellation Bluetooth • Converts 7.4VDC to 3.3VDC • Provides power to sensor RF Overall System system Transmitter Design Digital to Analog Ground Converter Station FPGA

The intended end use of our system will be continued research and development into the area of autonomous flight systems by knowledgeable engineering students and/or professors. User Interface

Power System ◦ Designed a step-down buck converter circuit to power the Wiimote sensors using the helicopter’s battery Required since the battery provides 7.4V and the Wiimote only requires 3.3V

We decided to use the controller in an unconventional way by directly changing the control voltages with a computer program We first measured the control voltages and recorded how they varied ◦ After carefully labeling the ◦ different control channels we stripped the controller of nonessential parts including the potentiometers First we tested our idea by ◦ connecting the controller to a controlled power source We finally connected the ◦ controller to a DAC and FPGA that allowed us to connect directly to our team laptop

Reading Xbox Controller ◦ Rewrote and adapted software being used by Korebot Project Reading Data from Wii Remote ◦ Altered existing Cwiid library Manipulating values appropriately ◦ Mapped Xbox inputs to helicopter throttle, pitch, roll and yaw values. ◦ Mapped sensor data to corresponding helicopter state values Autonomous Control System Sending data using RS232 Serial port ◦ Sends Channel Command followed by value to FPGA state machine. ◦ Found current maximum refresh rate of 2ms. ◦ Appropriate voltage levels are seen at the DAC outputs.

Set Points nts Physic ical al Θ s Y s X s Z s Beha havior vior Sensors Helico copte ter Sens nsor r Con ontroll roller ers Actuat uator ors Calcul ulati ations ns Inputs ts Yaw Ctrl Yaw Angle Yaw - P θ (t) t Ir 1:x Left/Right Ir 1:y Roll Ctrl Roll - Position PI PI Ir 2:x Y(t) Ir 2:y Pitch Forward/Back Ir 3:x Pitch - Ctrl Position Ir 3:y X(t) PI PI Ir 4:x Throttle Up/Down Ir 4:y Ctrl Position - Throttle PD PD Z(t)

Wii data analysis function completely re- written ◦ Improved efficiency (run time, memory usage…) , overall analysis capabilities (4 IR sets), expandability, and commenting significantly. Fabricated a cradle attaching Wii-mote to helicopter ◦ Modified existing Aluminum brackets and a portion of original Wii- mote case (This design proved difficult to work with and was discarded) ◦ Current mounting system utilizes Velcro to attach all additional components to the base platform Completed further sensor testing ◦ Constellations, data resolutions, disturbance spectrum characterization

IR Sensor Data vs Time Accelerometer Data vs Time Testing the Wii Remote sensors was a large part of determining how we could best use them to provide feedback to our control system and fly our helicopter. Above are two examples of some of the data from our sensors. The accelerometer plot also shows the effects of filtering out the disturbance/noise from the helicopter’s vibrations.

Flight testing was performed to determine how our control system reacted in real-time. Many adjustments were made in order to ensure the smoothest flight dynamics possible.

A presentation giving a general overview of the current technology involved in non-ISU UAV projects, both at other universities and in the general marketplace. A written report detailing: ◦ The capabilities of our platform. ◦ The sensors used in our systems operation. ◦ The overall processes and means by which our system operates. ◦ A summary of the development process. Our end product itself.

15% 15% Research Design 20% 25% Testing Documentation Implementation 25%

Cost Estimate for MicroCART-Phase 5 Cost Equipment Base Platform Donated Additional Platforms $ 180.00 Replacement Parts $ 10.00 Upgraded Batteries $ 20.00 Sensors Donated Tools and hardware $ 10.00 Reporting Project Poster $ 10.00 Bound Project/Design Plans $ 15.00 Labor 1324 hours at $20 per hour $ 26,480.00 Subtotal (without labor): $ 245.00 Total: $ 26,725.00

Position and orientation will rely less on IR communication More on-board portable sensors will be used ◦ accelerometers for roll and pitch ◦ sonic range finders for altitude ◦ magnetometers for heading ◦ GPS for absolute positioning Future research will be done to make the helicopter able to move to different points on a grid and able to fly outside

Recommend

More recommend