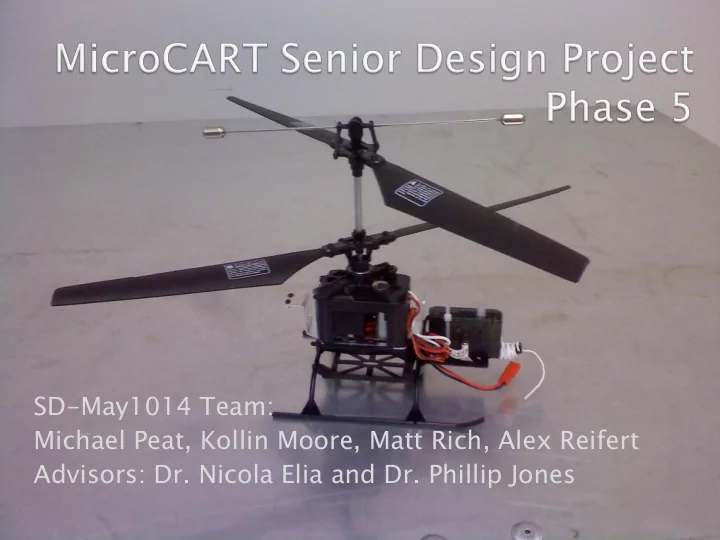

SD-May1014 Team: Michael Peat, Kollin Moore, Matt Rich, Alex Reifert Advisors: Dr. Nicola Elia and Dr. Phillip Jones

History ◦ MicroCART has been an active project since 1998. ◦ The project has been plagued by a: Lack of testing availability (weather, pilot, safety issues, etc…) Lack of cooperation between successive teams and passing on of undocumented knowledge Lack of consistent advising causing the lack of a systematic approach to designing a very complex end product Rationale for project restructuring ◦ Platform needed to be smaller. ◦ Platform needed to be more stable. ◦ Platform needed to be flown indoors. ◦ Control system needed to be simplified.

To create a small electrically powered autonomous flying vehicle capable of takeoff and landing from horizontal surfaces as well as stable indoor hover without human assistance.

Carnegie Mellon Georgia Tech 2009 Embry Riddle College of University Aerial Robotics Team Engineering Technische Universitaet Massachusetts Institute Berlin South Dakota School of Mines of Technology and Technology (SERV Robot)

Operating Environment: ◦ Indoors and Unobstructed Area ◦ Within Range of Position Tracking System End Use and Users: ◦ The intended end use of our system will be continued research and development into the area of autonomous flight systems. ◦ The intended users will be knowledgeable engineering students and/or professors.

The system will only be operated in the operational environment defined in the design document. Basic flight mechanics will be achieved by the base platform. There will be a ground station. Platform will have a limited payload capability. There will not be obstacles in the flight path.

The system shall be able to take off autonomously from a surface with no incline. The system shall be able to hover autonomously. The system shall be able to land autonomously on a surface with no incline. The system shall have a minimum battery life of 5 minutes under normal operation.

The system shall be no larger than 30”x30”x10” (LxWxH) The base platform shall be capable of carrying a payload of at least 0.125kg. The base platform shall be powered solely by batteries. The system shall be capable of wirelessly communicating with a ground station.

Onboard Sensors: Helicopter Flight • IR Camera • Accelerometer Mechanics • Wireless Transmitter Radio Controller Ground Station

Communication System Power System Software System UAV Mechanical Sensor System System

Communication System Power System Software System UAV Mechanical Sensor System System

Infrared Light Infrared Emitters Camera Onboard Bluetooth Microcontroller Transmitter 3 - Axis Accelerometer Minimal Option: Wii-mote sensors ◦ Infrared Camera Tracking System Single (per wii-mote)1024x768 Infrared Camera 4 Blob position tracking at 100Hz or more ◦ Inertial Measurement Unit 3 axis Accelerometer (ADXL330) 0.04g maximum acceleration resolution on all three linear axes Free fall frame of reference Normalized output readings (g=1)

Direct Wired Infrared Light Infrared Into Ground Emitter Cameras Station 6-axis Inertial Onboard Zigbee Measurement FPGA's and Wireless Unit Microcontroller Transmitter Optimal Option ◦ Infrared Camera Tracking System OptiTrac ™ optical motion capture system Six infrared cameras (lowest cost, larger numbers increase accuracy) Millimeter accuracy and resolution for the 3D location of markers depending on capture volume size and camera configuration. Currently Unavailable to us. ◦ Inertial Measurement Unit Highly accurate six degree of freedom accelerometer Still in production Likely ready for use mid next semester ◦ Other Options Researched: Indoor GPS, WIFI, RF Fingerprinting as well as several different IR camera systems

◦ Infrared Camera Tracking System Use: Accurate XYZ spatial coordinates over time Accurate Pitch Roll Yaw coordinates over time ◦ Inertial Measurement Unit Use: Fast response feedback on the dynamic movements of our platform More quickly than we would be able to achieve by position sensing alone Velocity and spatial coordinates for short intervals (option 2)

Communication System Power System Software System UAV Mechanical Sensor System System

Onboard UAV Power ◦ Base Platform 7.4V, 1000 mAh 2-cell Li-Po battery pack ◦ Power Conversion System Originally attempted to design simple voltage divider but ran into some critical flaws: Too much power wasted Changing load impedance Decided to implement a step-down DC-DC (buck) converter ◦ Power During Testing 0-40V, 0-10A DC power supply (Model 6267B by Hewlett-Packard) Ground Station Power ◦ Control System Power Wall plug-in for the PC/monitor ◦ Communications Power 8 AA batteries or optional AC/DC wall plug-in

Communication System Power System Software System UAV Mechanical Sensor System System

Information DAC to RC from On- Controller Board Sensors Computer UAV Control Processor System Sensor to Ground Station Communication ◦ Minimal Sensor System Option Broadcom 2042 HID Bluetooth ◦ Optimal Sensor System Option OptiTrack optical motion tracking Custom IMU Ground Station to UAV Communications ◦ Manipulation of 4-Channel Stock RC Controller Computer will send signals to a DAC which will send 4 separate voltages to the controller Use original 72.8 MHz FM transmitter to communicate with Base Platform Controller

Communication System Power System Software System UAV Mechanical Sensor System System

Output Data Controller Data Aquisition Data Input Data Transform Transform Transmission and Filtering • Outputs • Outputs • Outputs • Outputs: • Outputs • New Throttle • New Angular • Data Stream for • X, Y, Z positions • Actual Angular speed for Speed for both • New Yaw sending to the DAC both propellers. • X,Y,Z accelerations propellers described in the • New Pitch • Actual Blade Pitch for both • Pitch, Roll, and Yaw communications plan. • New Blade propellers. • New Roll Pitch for both propellers

Communication System Power System Software System UAV Mechanical Sensor System System

Sensor Mounting to Base Platform ◦ Minimal Sensor System Option Cradle system suspended below the battery cage Designed to produce no mid-flight instability ◦ Optimal Sensor System Option Will vary depending on sensor system physical dimensions and weight distribution Testing Platforms ◦ Anchoring System ◦ Damage Reduction System

4 screw locations for cradle mounting

Platform 1. Approximately 34 grams of unnecessary mass was removed from platform 2. Regular helicopter mass w/o battery is 190 grams 3. Stripped platform mass w/o battery is 156 grams 4. Current Battery (7.4V,1000mAh) mass is 50 grams \ 5. Flight ready regular helicopter mass is 240 grams 6. Flight ready stripped helicopter mass is 206 grams Minimal Sensor System Mass (Wiimote) 1. Original mass was of 82g lightened to 22g after removal of external casing and interface buttons Digital Scale 1. Capable of reading ounces or grams 2. Capable of negative mass readings (upward pull) 3. Maximum reading either way is 200 grams A detailed report and procedure are available on our website.

Outputs: Inputs: 1) Subplots of each acceleration for 1) Time each data set 2) x,y,z accelerations 2) Superimposed accelerations of all 1 st IR dot found (1 or 0) 3) data sets 1 st IR coordinates (‘x’, ‘y’) 4) 3) Subplots of pitch and roll calculated 1 st IR dot size (0 to 5) 5) from accels for each data set 2 nd IR dot found 6) 4) Superimposed pitch and roll for all 2 nd IR coordinates 7) data sets 2 nd IR dot size 8) 5) Subplots of each set of IR points coordinates (any length) X 12 OR (any length) X ◦ 4data sets 6) Superimposed IR coordinates for all data sets Up to 6 such sets at once ◦ Choice of including IR data or not (12 7) Superimposed xyz accelerations and ◦ pitch/roll for first data set or 4 cols) 8) Plots of the ‘x’ and ‘y’ coordinates *Will be extended to 4 IR input sets ◦ of each dot VS time when we can get WiiYourself source to compile 9) Optional: Vectors including the minimum step sizes for each acceleration as well as angle *Will be extended in the future ◦

◦ Accelerometer testing: 0.04g maximum resolution on linear axes ~2 degrees maximum resolution for pitch and roll, both by experiment and analysis Consistent outputs, though prone to some impulsive noise ◦ IR camera testing: 1 pixel resolution at distances up to 6 ft. Optimal range of operation greater than 4 ft. from IR Very consistent static outputs Highly noisy dynamic outputs (due to high sensitivity to vibration) Optimal filtering to be determined ◦ Large number of data sets as well as analysis function script available through our website

Recommend

More recommend