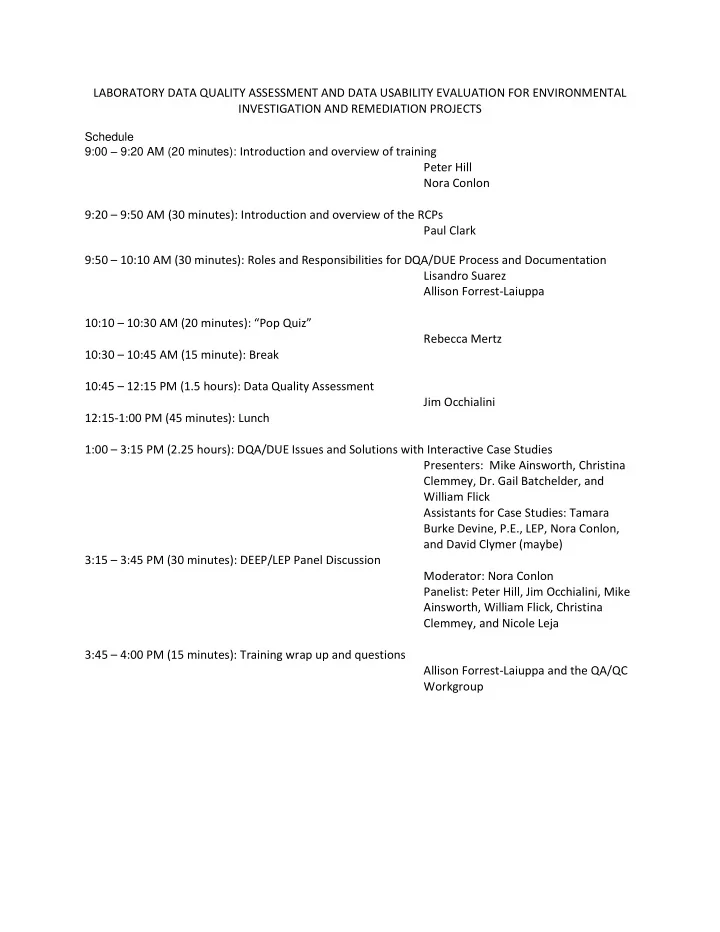

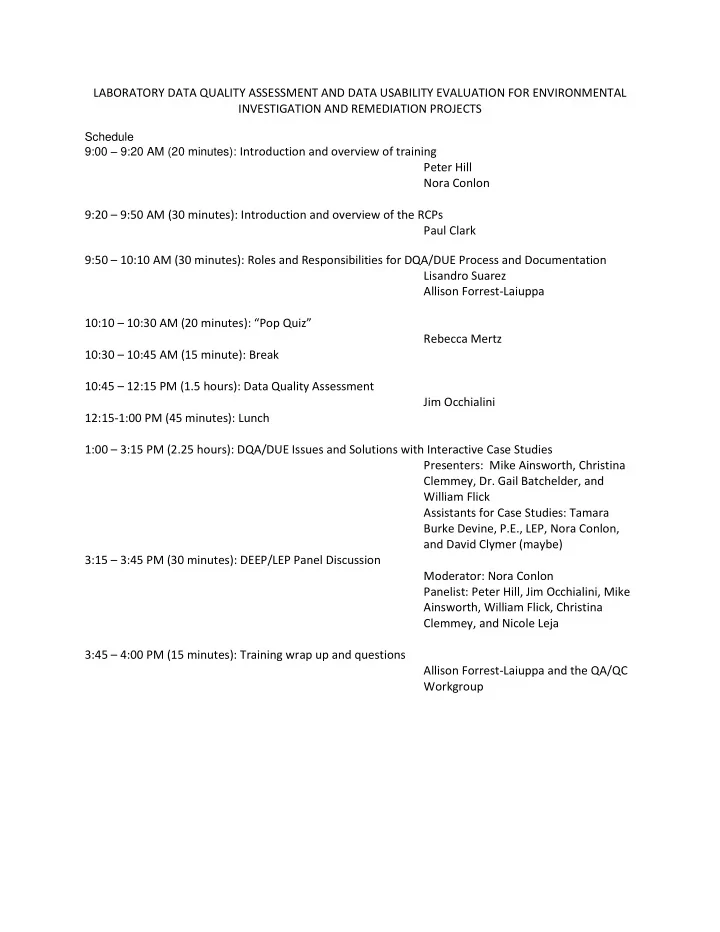

5/2/2017 “PARCCS” ‐ Data Quality Indicators • P recision • A ccuracy • R epresentativeness • C omparability • C ompleteness • S ensitivity Source: Ohio EPA • PARCCS parameters can be used to examine the quality of measurements and sampling efforts Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 2 Why Were the RCPs Developed? • SW ‐ 846 methods allow for flexibility with respect to QA/QC requirements. • QA/QC practices vary widely by laboratory – Undocumented QA/QC practices. – Inconsistency in QA/QC deliverables. – Inconsistency in laboratory performance. • RCPs based on Massachusetts Compendium of Analytical Methods. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 6

5/2/2017 Reasonable Confidence Protocols Key Concepts • RCPs were developed to standardize specific performance criteria for SW ‐ 846 Methods and to standardize deliverables from laboratory analysis • RCP methods provide analytical data of known quality Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 RCP Key Concepts • If Reasonable Confidence is achieved, the environmental professional can have “Reasonable Confidence” that the laboratory has followed the enhanced QA/QC procedures for analytical methods and reporting and has described non ‐ conformances. • “Reasonable Confidence” will form the basis for the review of the analytical data by the environmental professional to determine if the data is acceptable for the intended purpose. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 7

5/2/2017 Reasonable Confidence Protocols • Purpose – Data of Known Quality • LEPs MUST determine if that data of known quality meets their project objectives (Usable) – Alone, reasonable confidence is not enough – RCPs report non ‐ conformances that are evaluated as part of the DUE Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 Data Quality Assessment and Data Usability Evaluation The DQA/DUE process: • Provides confidence that the laboratory analytical data is of sufficient quality to support the decisions being made • Provides an accurate and consistent means to assess environmental impacts to land, water and human health • Reduces uncertainty and the risk (human health, financial, environmental) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 7 8

5/2/2017 Overview of the DQA and DUE Process Two ‐ step process: • 1st step is Data Quality Assessment (DQA) – identify and summarize QC non ‐ conformances. • 2nd step is Data Usability Evaluation (DUE) – determine whether or not the quality of the data is sufficient for the intended purpose. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 8 Data Quality Assessment • The DQA will identify and summarize any quality control problems that occurred during laboratory analysis. • The DQA should be performed throughout the course of the project. • The DQA must be performed prior to the DUE Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 9 9

5/2/2017 Data Usability Evaluation • The DUE is an evaluation by the environmental professional of the results of the DQA to determine if the analytical data are of sufficient quality, and are usable for the intended purpose. • A primary purpose of the DUE is to determine if any bias in the analytical results affects usability. • The affect of the bias can be evaluated by considering different types of laboratory QC information (multiple lines of evidence). Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 10 Data Usability Evaluation The environmental professional will also use the results of the DQA to evaluate the usability of the analytical data within the context of the project ‐ specific objectives and the conceptual site model (CSM). This includes considering: • volume of data available for the site • screening ‐ level data • field observations Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 11 10

5/2/2017 Types of Analytical Data Type of Data Description Data Quality Assessment Analytical data generated using the Evaluate precision, accuracy, RCP Data RCPs. and sensitivity. Analytical data generated from Demonstrate equivalency with samples collected after September 1, the Reasonable Confidence 2007 using a non ‐ RCP method where Protocols ‐ RCP Equivalency there is an existing RCP method (use Determination Request Form Reasonable Confidence Equivalency required. Evaluate precision, Non ‐ RCP Data Determination Form); OR, accuracy, and sensitivity. Analytical data generated from Evaluate precision, accuracy, samples collected after September 1, and sensitivity using QC data 2007 when no RCP method is equivalent to a similar RCP published. method. Use existing QC data to evaluate precision, accuracy, Analytical data generated prior to and sensitivity. September 1, 2007 that were not Pre ‐ RCP Data If precision and accuracy QC generated using an RCP method. data are not available, evaluate sensitivity. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 12 DQA and DUE Flow Chart Start Collect Additional Lab or Collect Additional Lab or Field Data Modify/Expand Field Data CSM Investigation Modify/Expand Investigation/Remediate Analytical Data, Field Sampling Plan, Field Observations, QA/QC, and Method Hydrogeological and Selection Physical Data Representativeness DQA – Identify Non ‐ Conformances Evaluation NO Does the Information/Data Represent the Site and Support the CSM? DUE ‐ Are the Analytical Data Adequate for the YES NO Intended Purpose Based on a Review of QC Non ‐ conformances YES and Information? Data is Representative and of Adequate Quality to Support Environmental Professional’s Opinion Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 13 11

5/2/2017 Questions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 14 Detailed look at The Reasonable Confidence Protocols Paul Clark DEEP paul.clark@ct.gov Connecticut Department of Energy and Environmental Protection 1 12

5/2/2017 What’s In the RCPs? • Performance criteria for laboratories regarding calibration, quality control, and reporting. • Guidance on what the laboratory should do if analytical problems are encountered. • Uniform target compound lists. • Required laboratory deliverables. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 2 General Description of the RCPs • Overview of Method: – Reporting to lowest calibration standard. – General QC performance criteria. • Sample Preparation Requirements. • Analysis Description. • Interferences. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 13

5/2/2017 Details of RCPs • Analyte List: – All compounds calibrated and reported unless directed differently by the environmental professional. • Reporting Specifications: – Batch MS/MSD not reported. – Results below RL reported as “ND”, No “J” flags. – Specific list of report deliverables. – Soils/Sediments on dry weight basis. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 Details of the RCPs • Holding Times. • Preservation. • Sample Container Types. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 14

5/2/2017 Importance of Table 1A • Each RCP method has a Table 1a • Summarizes the QC performance criteria Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 RCP Laboratory Certification Form • Performance criteria for labs to certify the data meets RCPs with exceptions noted in narrative. – 7 questions – Requires signature – Can’t be altered Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 7 15

5/2/2017 Laboratory Narrative • All reports must have a narrative. • Describe in detail all non ‐ conformances. • Provide all samples and analytes effected. • Narratives should be sample ‐ specific, as appropriate. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 8 Laboratory Communication • Often laboratory data does not meet intended use due to wrong compound list, incorrect method employed, reporting limits too high, etc. • Problems can be avoided by listing project data requirements before sampling, for example in a project QAPP or work plan. AND • Communicating the requirements to the laboratory. ‐ The Project Communication Form, or other similar document, can be used for this purpose. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 9 16

5/2/2017 What Methods Currently Have RCPs? • 8260 Volatile Organics • 8270 Semivolatile Organics • 8081 Pesticides • 8082 Polychlorinated Biphenyls (PCBs) • 8151 Chlorinated Herbicides • 8021 Volatile Organics • 1311 Toxicity Characteristic Leaching Procedure (TCLP) • 1312 Synthetic Precipitation Leaching Procedure (SPLP) • 7196 Determination of Hexavalent Chromium • ETPH Extractable Total Petroleum Hydrocarbons Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 10 What Methods Currently Have RCPs? • 6010 Inductively Coupled Plasma ‐ Atomic Emission Spectrometry • 6020 Determination of Trace Metals • 7470/7471 Determination of Mercury • 7000 Series Determination of Metals • 9010/9012/9014 Determination of Total Cyanide • T0 ‐ 13A PAHs • TO ‐ 15 Volatile Organics • TO ‐ 17 Volatile Organics • VPH Volatile Petroleum Hydrocarbons • EPH Extractable Petroleum Hydrocarbons • APH Air ‐ Phase Petroleum Hydrocarbons Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 11 17

5/2/2017 Questions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 12 Roles and responsibilities for DQA/DUE Lisandro Suarez DEEP lee.suarez@ct.gov Connecticut Department of Energy and Environmental Protection 1 18

5/2/2017 Guidance Document: DQA/DUE Communication Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 2 Environmental Professional’s Responsibility During Project Setup: – QAPP/RCPs – Project Objectives and CSM • Source and number of samples • Sampling methods, sample handling & QC requirements – Communicate with laboratory • Request appropriate sampling containers, preservation, holding times, and archiving of samples • Request appropriate reporting limits & RCP method – Provide a Chain of Custody and properly preserved samples within holding times Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 19

5/2/2017 Laboratory’s Responsibility • The Lab provides the Environmental Professional and others with: – Sample containers with preservative – Sign off on Chain of Custody – Laboratory Data with QA/QC information Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 Laboratory’s Responsibility • The Lab provides the Environmental Professional and others with: – Laboratory Analysis QA/QC Certification Form • 7 questions with signature – Narrative of non ‐ conformances – Answer questions when asked Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 20

5/2/2017 Environmental Professional’s Responsibility • Upon Receiving Data Package: – Review Laboratory Data Package for completeness in a timely manner • Review RCP Certification Form • Review Narrative and Chain of Custody and look for any QA/QC issues • Communicate with laboratory if there are any issues with the package – Review and evaluate the laboratory data and non ‐ conformances in a timely manner • Communicate with laboratory if there are any questions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 Environmental Professional’s Responsibility • Perform/Document DQA/DUE Process – Review QA/QC • Look beyond narrative and review laboratory data – Assess the quality of the data – Evaluate the usability of the data – Demonstrate and document an understanding of the quality and usability of the data for reporting purposes Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 7 21

5/2/2017 Questions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 8 Documenting the DQA/DUE Process Allison Forrest ‐ Laiuppa DEEP allison.forrest ‐ Laiuppa@ct.gov Connecticut Department of Energy and Environmental Protection 1 22

5/2/2017 Common problems with documentation • RCP method Laboratory narrative cluttered with extras, not just non ‐ conformances • DQA/DUE is not done at all • DQA/DUE is not well documented – Is not succinct – Does not show review beyond lab narratives • Incorrect use of method detection limit instead of reporting limit Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 2 Concepts of Good DQA/DUE Documentation • Well documented DQA/DUE • Understanding and appropriateness to the project objectives – Screening Characterization Compliance Verification? – Regulatory Criteria • Understanding of the Conceptual Site Model – History of site and previous environmental data – Representativeness and uniformity of samples collected Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 23

5/2/2017 Concepts of Good DQA/DUE Documentation • Discusses essential non ‐ conformances – Evaluates precision, accuracy, and sensitivity of the data and how they may impact the usability of the data – Considers multiple lines of evidence • Includes review of Chain of Custody • Explains possible impacts to data outside of laboratory analysis • Is concise Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 Example of DQA Worksheet Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 24

5/2/2017 Example of DUE Worksheet (page 1) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 Example of DUE Worksheet (page 1, continued) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 7 25

5/2/2017 Example of DUE Worksheet (page 2) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 8 Example of a DQA/DUE Text Summary One soil was collected at the Cleaners property at 967 Breadbaker Lane, Nowhere CT and submitted to a state ‐ certified analytical laboratory for volatile organic compounds (VOCs) using the Reasonable Confidence Protocol (RCP) Method 8260. This sample was collected to confirm the results of a previous investigation that concluded that a PCE release area is located near a location used for dry cleaning filter storage. The site was used a dry cleaners for at least 40 years from 1950 to 1990. A data quality assessment and data usability evaluation was performed for data generated in accordance with CT DEEP guidance and noted the following quality control nonconformances. Methylene chloride was found in a laboratory blank and in a sample at a concentration less than the class GA Groundwater Protection Criteria (GAPMC) as a result of laboratory contamination. Continuing Calibration, Laboratory Control Samples, and Matrix Spike/Matrix Spike Duplicates exhibited bias for poor performing compounds and several other compounds that are not constituents of concern at the release area. The sample was not frozen within 48 hours of collection and exhibits low bias for VOCs. Tetrachloroethene detected in sample at 400 μ g/kg well above GA PMC of 100 ug/kg. Groundwater data indicates that a PCE release has occurred at the site. Based on the above findings from the DQA and DUE, the analytical data is adequate quality and of sufficient accuracy, precision, and sensitivity to confirm that remediation of this release area is required. Further investigation will be conducted to characterize the extent this release area. DQA Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection and DUE worksheets are included in the appendix to this document. 9 26

5/2/2017 Reports should include • Discussion of your site decision and data usability statement • Laboratory Data and Narratives • RCP Analysis and RCP QA/QC Certification Form • Chain of Custody Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 10 Reports should include • DQA/DUE Worksheets or documentation of thought process • Summary of the evaluation all QA/QC issues and laboratory non ‐ conformances • Any other pertinent information Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 11 27

5/2/2017 Questions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 12 Quiz Time Multiple Choice A. Yes B. No C. It Depends Rebecca Merz Eurofins Spectrum Analytical, Inc. RebeccaMerz@EurofinsUS.com Connecticut Department of Energy and Environmental Protection 1 28

5/2/2017 Does the laboratory need to know that your project falls under the CT RCP program and this form should be included with your report? Connecticut Department of Energy and Environmental Protection 2 Surrogates Outside Criteria LEP Joe submitted two 1L ambers for 8270 analysis for standard TAT and notes SWPC criteria needs to be achieved. Acenaphthene is the COC (SWPC = 0.3ug/L). When you receive your lab report the narrative states that the surrogate recovery for this sample is outside of established control limits due to a sample matrix effect. The lab has re ‐ extracted and confirmed matrix interference, however, the re ‐ extraction was performed outside holding time. Acenaphthene reportable concentration (original) 0.26 ug/L (re ‐ extract) 0.29ug/L Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 29

5/2/2017 Chain of Custody 101 Does your chain need to match your labels for the following? sample ID, collection, date, time, and project name/site location? Do you need to be specific with your methods? Metals… If using container caps to write information should the same information must be on the label? Connecticut Department of Energy and Environmental Protection 4 Laboratory Blank Contamination associated to Metals samples Table 1A Specific QA/QC Requirements and Performance Standards for Method 6020 CASE NARRATIVE: SW846 6020A ‐ Arsenic The method blank contains analyte at a concentration above the MRL; however, concentration is less than 10% of the sample result, which is negligible according to method criteria. Connecticut Department of Energy and Environmental Protection 5 30

5/2/2017 • The result reported for PCE is flagged "E" or estimated because the result was above the calibration range of the instrument. The lab performed a dilution. – Should both sets of data be included in the lab report? – Which result should be used for ND concentrations? Connecticut Department of Energy and Environmental Protection 6 LCS/ LCSD Low Bias Barium percent recoveries (83/79) are outside individual acceptance criteria 85 ‐ 115. Results of the following samples are considered to have a potentially low bias. • Given the example below what are some DUE considerations? Connecticut Department of Energy and Environmental Protection 7 31

5/2/2017 What is wrong with this VOC Sample? What potential issues might the lab have during analysis? Connecticut Department of Energy and Environmental Protection 8 15 Minute Break Connecticut Department of Energy and Environmental Protection 32

5/2/2017 Data Quality Assessment (DQA) Jim Occhialini Alpha Analytical jocchialini@alphalab.com Connecticut Department of Energy and Environmental Protection 1 Topics for Discussion • Overview • Quality • Data Quality Assessment (DQA) • Data Usability Evaluation (DUE) • Data Management • Lab Report Review Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 66 2 33

5/2/2017 Why is Data Usability Important?? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 It’s all about managing uncertainty… and incorporating that uncertainty into your decision making risk of wrong decision CERTAINTY Risk Tolerance Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 34

5/2/2017 Relationship Between Risk Tolerance & Uncertainty • Do you evaluate all your data the same way? – Final clean up verification samples vs. initial site screening? • Level of scrutiny applied to laboratory data commensurate with what it will be used for – Risk assessment? – Locate “hot spots”? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 Sources of Uncertainty Field / Sampling Lab = + calibration contaminant distribution / preparation homogeneity performance sample location rationale QA program ‐ QUALITATIVE sampling method + ‐ QUANTITATIVE preservation & handling Total Uncertainty Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 35

5/2/2017 Regulatory Approaches to Managing Uncertainty • EPA – Program wide approach • CERCLA (“superfund”) – Contractor laboratory program (CLP) - PRESCRIPTIVE – Project specific approach • RCRA – SW-846 GUIDANCE – Quality Assurance Project Plans (QAPPs) – Data Quality Objectives (DQOs) for RI/FS ~1984 • States – Program wide approach • CT Reasonable Confidence Protocols (RCP) ~2006 – RCP DQA/DUE • MA Compendium of Analytical Methods (CAM) ~2003 – MCP REDUA 2007 • NJ DEP Technical Guidance 4/2014 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 71 7 Wait a minute…aren’t labs CERTIFIED? 72 8 36

5/2/2017 CERTIFIED MEANS: YES, you’re qualified… Certification is provided through a formal process of application, audit and approval of a laboratories' quality system. Certification must be renewed annually Com prehensive, w ell thought-out process, based on approval of a “laboratories’ quality system ”… Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 73 9 ... so lab certification means everything is in place to produce “data of known quality” Doesn’t mean that all data generated by the lab is of known quality …or the data in your report 10 37

5/2/2017 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 11 LABORATORY QA/QC OVERVIEW Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 12 38

5/2/2017 QA & QC Separate Functions • Quality Control – (2 components) 1. “QC infrastructure” 2. Continuing monitoring / documenting data quality 1. Internal lab system control & project ‐ specific DQI info • Quality Assurance • Assures the QC is performed, “enforcer” • Systematic & performance audits • Does the lab perform internal audits? • Follow up on corrective actions? Quality System Connecticut Department of Energy and Environmental Protection 13 “Reasonable Confidence Process”… – Data Quality Assessment (DQA) – Identify non ‐ conformances – Data Usability Evaluation (DUE) – Impact of non-conformances on your use of the data 78 14 39

5/2/2017 …so what do we mean by “data quality”? The degree of qualitative & quantitative uncertainty that exists in the data set 79 15 How Do You Evaluate PARCCS Data Quality? P recision – Expression of Variability, how reproducible is the data? A ccuracy – Expression of Bias, observed versus true value R epresentativeness – Does the data provide a true reflection of the actual site conditions? C ompleteness – do I have enough usable data to support decision making? Valid data for identified critical samples? C omparability – “apples to apples” Are multiple data sets valid comparisons? S ensitivity – do the reporting limits support regulatory criteria? 80 16 40

5/2/2017 What is data of known quality??? Known PARCCs From the laboratory perspective – The accuracy, precision and sensitivity is ascertainable What it isn’t necessarily … 81 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 18 41

5/2/2017 How Do You Get Data of Known Quality Level of uncertainty is known … HOW? 1. Data generated & reported in accordance with an ”RCP” protocol 2. Data generated & reported with a full data deliverables package Incorporating a comprehensive QAPP & complete data validation 3. Lab followed SPECIFIC, WELL DOCUMENTED methods With detailed performance, QC requirements and corrective actions Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 19 Data Quality Assessment ‐ Starting the Process RCP compliant data and… • – QUESTION 4 “Were all QA/QC performance criteria specified in the DEEP Reasonable Confidence Protocol documents achieved? ” “YES” • Further data quality assessment may not be necessary – LEP should still review the data – Known quality data, WITH NO NON-CONFORMANCES • Data usable as is for all applications – Still need to review reporting limits versus regulatory criteria Unfortunately… Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 20 42

5/2/2017 There are usually some non-conformances… Document them as part of the DQA Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 21 Data Quality Assessment • Where do I start? – LAB NARRATIVE (list of non-conformances) • Includes all issues of significance to data user: method performance problems, QA/QC outliers, etc. – Lab report BATCH QC summary data section – Lab report SAMPLE SPECIFIC QC data pages • What do I need to know? – Data quality indicators (info for usability purposes) • Accuracy • Precision • Sensitivity (reporting limits) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 22 43

5/2/2017 Accuracy – Evaluation of Bias that Exists in the Measurement System • Is there bias? – Lab measurement system in control? – Sample - specific interferences? Spike recovery: MV X 100 = %R TV Where MV = Measured Value & Data quality indicators ‐ TV = True value measurement tool: blanks & spikes %R can indicate positive or negative bias Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 23 Accuracy ‐ Lab Data Quality Indicators Lab Batch QC • Lab control sample (LCS) if done in duplicate … (LCS / LCSD) – Baseline accuracy determination, entire target analyte list – Potential POSITIVE or NEGATIVE bias • Matrix spike/matrix spike duplicate (MS/MSD) • Same as LCS/LCSD w/spike added to actual sample • Laboratory method blank – False positive indicator, potential POSITIVE bias Sample Specific QC • Surrogate Spikes Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection – Chemically similar subset of analytes • Added to every sample (organics analysis) 24 44

5/2/2017 Accuracy – Additional Data Quality Indicators Sample Specific QC • Surrogate Spikes – Chemically similar subset of analytes • Hold times (sample & parameter specific QC element) – False negative indicator, potential NEGATIVE bias Field QC • Matrix spike/matrix spike duplicate (MS/MSD) * • Same as LCS/LCSD w/spike added to actual sample • Field, trip, and/or equipment blank (field QC samples) – False positive indicator, potential POSITIVE bias Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 25 Evaluating Accuracy Where does the criteria come from? What’s in your report? Example Example Acceptance Recommendation %R Criteria 55 70 - 130 Negative bias 147 70 - 130 Positive bias • %R used for surrogates, LCS/LCSD & MS/MSD – Don’t do the math! Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 26 45

5/2/2017 Interpreting Accuracy Bias result spike %R action level acceptance criteria 50 22% 55 75 – 110 % 50 47% 1 75 – 110 % Interpretation: Positive / negative bias vs . Relationship of data point to the action level vs. Specific use of the data Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 27 VOC Surrogate Spike Data report data page Reported for each sample at the end of the target compound list Surrogate %R does not automatically indicate that a QC issue exists for a specific compound – MS can be used to evaluate performance of a specific compound Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 28 46

5/2/2017 Precision – Expression of Reproducibility & Variability • How reproducible is the lab measurement system? • Sample homogeneity? |R 1 – R 2 | X 100 = %RPD (R 1 + R 2 ) /2 Precision measurement tool: replicate analyses % RPD = the absolute value of the range divided by the mean times 100 E valuated using relative percent difference (RPD) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 29 Precision ‐ Expression of Reproducibility & Variability Laboratory generated precision information: • (LCS / LCSD) – Two analyses –> results compared (%RPD) for precision – • Laboratory batch duplicates Field generated precision information: • Field duplicates, co-located samples, MS/MSD – Submit “blind”, calculate RPD Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 30 47

5/2/2017 Evaluating Precision Example Example Acceptance Recommendation Criteria (%RPD Upper Limit) RPD 14 25 Precision with within acceptable range 35 25 Precision outsi outside acceptable range • %RPD acceptance criteria represents an upper limit – Greater the RPD, more variability (less precision) • %RPD used for LCS/LCSD, MS/MSD, lab/field duplicates Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 31 Interpreting Precision Information • Sources of variability 1. measurement system performance (lab & field) reproducibility issues 2. sample non-homogeneity, media variability (field) representativeness issues • Evaluating replicate non-agreement – Field / lab duplicate samples (conservative, use > result) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 32 48

5/2/2017 VOC LCS / LCSD Data 97 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 33 IF LCS %R indicated LOW BIAS accuracy (biased low) If LCS/LCSD RPD was 43% precision 3 4 5 6 7 8 9 10 11 12 13 Reported result - “9” Highest allowable variability (25% RPD) of associated LCS/LCSD Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 34 49

5/2/2017 Sensitivity (Laboratory Reporting Limits) Reporting Limit What action levels do Sample Response: you need to meet? 17500 May not be attainable with routine methods Sample Concentration: 17 PPM lowest cal std Elevated RLs due to dilutions: • High target (or non ‐ target) compound concentration • Difficult sample matrix, spikes diluted out? MDL* MDL Preparative Analysis 1000 mL aqueous Sample Extraction sample • “winnowing down” process extraction 300 mL – isolate (extract) & concentrate organic • exploit solubility difference solvent concentration • primary source of method sensitivity 1 mL organic and…method performance problems solvent extract 1 mg/L (instrument RL) 1000x concentration factor = 1 ug/L method sensitivity 36 50

5/2/2017 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 37 So You’ve Documented the “Non-Cons”… Do the DUE Is the data usable? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 38 51

5/2/2017 Data Collection Process Objective: Collect Data of Known Quality Suitable for its Intended Use • Planning – project set up • Involve all data users • Field staging / lab set up • Execution • Collect & analyze samples • Data management project follow up • DQA / DUE • Meet my needs? Is it usable? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 39 You’ve Completed the DQA Are the Data Usable? Focus… • Why did the report get a “NO” on Question 4 (RCP) ? • What else did your DQA find? – Isolate analysis • Isolate analytes – This is the data that needs to be evaluated • Everything else is OK to use “as is”… – Still need sensitivity evaluation Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 40 52

5/2/2017 Data Usability Evaluation Process • Completed DQA – Summary of non ‐ conformances DUE – what does it mean for my project? • Evaluate relevancy – Contaminant of concern? Sample location? Significance? • Bias: +, ‐ or indeterminate? • Relationship of result to regulatory criteria • Incorporate uncertainty into decision ‐ making – Does this non ‐ conformance impact my use of the data? – RISK TOLERANCE Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 41 DUE: Additional Considerations • Multiple lines of evidence – Batch QC DQIs / sample specific DQIs • Additive or contradictory effect? – Bring in info beyond current lab report • Historical data, field data, other samples, CSM, etc. • Trade offs – Non-conformance severity (17% R or 70% R) • Importance of this data point / risk tolerance? – Is the non-conformance tempered by facts? • (dilution, co-elution, obvious sample matrix issues…) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 42 53

5/2/2017 Evaluating Significant QA/QC Variances • Excessive QC non ‐ conformances – Rejected data – Intended use & risk tolerance dependent – Would require substantial justification Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 43 So…Is the Data Usable? Can you justify it? Can you make the case for using qualified results for your project application? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 44 54

5/2/2017 Managing Usability Information • Summarize your data qualifications – Table summary (Exception Report NON-CONFORMANCES? ) – Integrate into project data base • Use data usability -qualified data for all decision making • Reminder – you really should have an understanding of data limitations ongoing as decisions are made Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 45 I ‐ 2 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 110 46 55

5/2/2017 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 47 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 48 56

5/2/2017 Data Usability Table Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 49 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 50 57

5/2/2017 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 51 www .epa.gov/superfund/programs/clp/download/somnfg . pdf Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 52 58

5/2/2017 www.epa.gov/oswer/riskassessment/datause/pdf/datause ‐ parta.pdf Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 53 Laboratory Report Review • You are the LEP of record • Site history • Currently truck maintenance facility • Post ‐ remediation analytical data • DQA/DUE to support decision ‐ making Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 54 59

5/2/2017 55 DQA DUE Data • Review RCP certification form • Review non-conformance narratives & QC information QC “non ‐ Data use cons” – Accuracy, Precision & Sensitivity Results, reporting limits good fit? COCs, Reg Criteria Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 120 56 60

5/2/2017 CONCEPT DQA: Find non ‐ conformances DUE: Evaluate impact of non ‐ conformances Triage – what’s important? • COC…or not? • What are we looking for? • Sample location…significant? • Other project specific driver… – “No” answers on Questionnaire – Narrative comments – QC outliers • QC summary sections • Data pages for sample ‐ specific QC Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 57 58 61

5/2/2017 RCP Summary Questionnaire Any “No”s? QUESTION 4: NO QUESTION 5b: NO Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 59 Question 5b: Were these reporting limits met? NO • Why the “NO” answer? – Check the narrative, use data table • 1,2 ‐ Dibromo ‐ 3 ‐ chloropropane – Run by Method 8260 (RL 2.5 ug/L) • Alternative Polluting Substance Criteria 0.2 ug/L – Alternative methods not requested • Not contaminant of concern at this site Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 60 62

5/2/2017 Question 4: Were all QA/QC performance criteria specified in the DEEP Reasonable Confidence Protocol documents achieved? NO (not a big surprise) • For most projects, you should not expect a “YES” to this question… • Proceed to narrative Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 61 VOC Surrogate Spike %R Non ‐ Conformance (page 14) Sample ‐ specific QC (only applies to Sample L1704848 ‐ 02) Surrogate spike % Recovery Acceptance Criteria (%R) Compound 57% 70 – 130% 1,2-dichloroethane-d4 Sample was re ‐ run (pages 15 ‐ 17) similar surrogate performance (54%R) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 62 63

5/2/2017 VOC Sample L1704848 ‐ 02 Low Surrogate %R • Data usability impact? – Negative bias • Actual results could be greater than reported value – Data reported could be less conservative • Implications – This sample only, applies to entire TCL – Re ‐ run confirms sample ‐ specific matrix effect – BTEX hits, rest of TCL ND (both runs) • SERIOUS ISSUE, BTEX COCs w/ negative bias indicated – DUE implications Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 63 VOC LCS / LCSD Non-Conformances LCS / LCSD (over-recoveries - compound specific) • Analytical Batch QC (applies to all samples run in this batch) Compound LCS %R LCSD %R Acceptance Criteria %R 155 155 70 - 130 4-methyl-2-pentanone 2-butanone 153 153 70 - 130 2-hexanone 154 154 70 -130 (Pages 24 - 27) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 64 64

5/2/2017 VOC LCS / LCSD Non ‐ Conformances (over ‐ recoveries) • Data usability impact? – Batch QC: Applies to all samples run in this batch – Positive bias scenario • Actual result could be less than reported value – Data for these compounds is more conservative • Implications? – ND reported for each compound, w/positive bias – Cmpds are not contaminants of concern – Cmpds are considered poor performers • NO ISSUE, no DUE implications Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 65 VOC LCS/LCSD Non ‐ Conformances (under ‐ recoveries – compound specific) Analytical Batch QC (applies to all samples run in this batch) LCS %R LCSD %R Acceptance Compound Criteria 98 70 – 130 Benzene 47 RPD 70% 70% RPD 20% (Page 24) Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 66 65

5/2/2017 LCS / LCSD Recoveries (benzene under ‐ recovery) • Data usability impact? – Batch QC: Applies to all samples run in this batch – Negative bias • Actual result could be greater than reported value • Data reported could be less conservative • Implications? – Cmpd is a contaminate of concern – Multiple lines of evidence supporting negative bias for sample ‐ 02 Benzene result {surrogate & LCS} • SERIOUS ISSUE, Benzene a COC w/ negative bias indicated – DUE implications Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 67 68 66

5/2/2017 VOC DQA Non ‐ Conformances of Concern Sample Samp le ID ID or or CMPD CMPD Initia itial Re- e- De Decision / sion / rationale onale QC elemen QC element Analysis Analysis Benzene low bias, applies LCS %R Benzene 47% NA to both samples Low %R L1704 L170484 848-02 All cmpds 57% 54% 1,2-DCA d4 All TCL Probable low bias Surrogate Benzene LCS low %R L1704848-01 Benzene <0.5 ug/L NA Probable low bias Benzene LCS low %R L1704848-02 Benzene 0.7 ug/L NA Probable low bias L1704848-02 Benzene 0.7 ug/L 0.7 ug/L Surrogate low %R probable low bias, all cmpds L1704848-02 Surrogate low %R probable All cmpds All “hits” & All “hits” & low bias, all cmpds NDs NDs Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 69 VOC Data Usability Evaluation (DUE) Summary • Sample L1704848 ‐ 02 initial & re ‐ analysis – Both 0.7 ug/l benzene , GW Quality Criteria: 1.0 ug/L • MLE indicate negative bias (surrogate, LCS) – Both results just below reg criteria – Action? • Sample L1704848 ‐ 01 – Benzene ND at 0.5 ug/L • With low bias indicated (LCS) – is it really ND? • Samples ‐ 01 & ‐ 02 positive bias – 4 ‐ methyl ‐ 2 ‐ pentanone, 2 ‐ butanone, 2 ‐ hexanone – Positive bias w/all NDs, not COCs, No data usability impact Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 70 67

5/2/2017 SVOC Non ‐ Conformances (Page 50 ‐ 51) LCS / LCSD Recoveries and RPDs DQA Review Analytical Batch QC (applies to all samples run in this batch) Compound LCS LCSD %RPD %R RPD Acceptance %R %R Criteria Criteria Benzo(a)anthracene 33 41 22 40 – 140 30% 33 27 20 30 – 130 30% 2,4-Dimethylphenol Benzo(a)pyrene 30 40 29 40 -140 30% Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 71 SVOC LCS / LCSD Recoveries DUE Thought Process • Data usability impact? – Negative bias • Actual results could be greater than reported value • Data reported could be less conservative • Implications? – All 3 cmpds “slightly below” acceptable %R range • SERIOUS ISSUE (?), COCs w/ negative bias indicated – DUE implications • Need to evaluate results in relation to action levels Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 72 68

5/2/2017 SVOC DUE Thought Process MLE • PAHs ‐ benzo(a)anthracene, benzo(a)pyrene – “OUT”: Low bias (LCS) • Impacts all 3 samples – “IN”: LCSD, MS/MSD, surrogates, blank acceptable & FD – Sample ‐ 03 ND (<110 / 140 ug/Kg) – FD results • BAA: 200 / 180 hit versus 1,000 regulatory criteria – OK? • BAP: 500 / 470 hit versus 1,000 regulatory criteria – OK? • CONTEXT? COC, use of data, “body of work”, EPC? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 73 SVOC DUE Thought Process (multiple lines of evidence) • Dimethylphenol – “OUT”: Low bias (LCS, “just out”) • Impacts all 3 samples – “IN”: LCS, MS / MSD, surrogates, blank, FD acceptable – DMP: all 3 samples <180 ND versus 2,800. regulatory criteria • OK? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 74 69

5/2/2017 SVOC MS/MSD Non ‐ Conformances (DQA summary) – Analytical Batch QC (but applies to sample ‐ 01 only) – (Page 55 ‐ 58) Compound MS MSD %RPD %R RPD Acceptance %R %R Criteria Criteria 38 48 23 40 – 140 30% Bis(2chloroethyl)ether Benzo(k)fluoranthene 38 48 23 40 – 140 30% 20 32 46 30 -130 30% Pentachlorophenol Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 75 SVOC MS/MSD Data DUE Thought Process… Action ? • Data usability impact? – Negative bias • Actual results could be greater than reported value • Data reported could be less conservative • Implications? – Similar situation as with LCS data • COCs w/ negative bias indicated, DUE implications • Need to evaluate results in relation to action levels Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 76 70

5/2/2017 SVOC Data Usability Evaluation Summary (DUE multiple lines of evidence) • PAHs ‐ Benzo(k)fluoranthene – “OUT”: Low bias (MS/MSD, “just out” ) – “IN”: LCS / LCSD, surrogates, blank acceptable & FD – ‐ 03 ND (<110 ug/Kg), ‐ 04 (0.12 & ND) vs 1,000 ug/kg criteria – FD identical result • BKF: [120 hit / <110] versus 1,000. regulatory criteria – OK? – CONTEXT? COC, use of data, “body of work”, EPC? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 77 SVOC Data Usability Evaluation Summary (DUE multiple lines of evidence) • Bis 2 ‐ chloroethylether – “OUT”: Low bias (MS/MSD, “just out” ) • soil samples all ND (<180) – “IN”: LCS / LCSD, surrogates, blank acceptable & FD • FD identical result (<180) • BCEE: <180 result versus 1,000 regulatory criteria – OK? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 78 71

5/2/2017 SVOC Data Usability Evaluation Summary (DUE multiple lines of evidence) • Pentachlorophenol – “OUT”: Low bias (MS/MSD, “way out”), FD %RPD – “IN”: LCS / LCSD, surrogates, blank acceptable • # ‐ 03 : <140 hit versus 1,000 regulatory criteria (low MS) • #s ‐ 04/FD: 700 / 2,200 versus regulatory criteria 2,200 ‐ 04 & ‐ 05 FDs? 103% RPD 700 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 79 SVOC DUE Summary CMPD CMPD MS/MSD MS/MSD -03 -03 -04 -04 -05 05 Crite Criteria LCS/ LCS/LCSD mg/Kg mg/Kg (FD -04) (FD -04) Mg/K Mg/Kg (-03) (-03) 1.0 low bias <0.110 0.200 0.180 Benzo(a)anthracene <0.180 <0.180 <0.180 2.8 low bias 2,4-Dimethylphenol OK OK 1.0 low bias <0.14 0.500 0.470 Benzo(a)pyrene <0.180 Bis 1.0 low bias <0.180 <0.180 (2chloroethyl)ether <0.110 1.0 Low bias 0.120 <0.110 Benzo(k)fluoranthene OK OK “significant” 1 <0.140 0.700 2.2 Pentachlorophenol low bias Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 80 72

5/2/2017 EPH Non ‐ Conformances (pages 62 ‐ 63) • EPH COD extraction surrogate – Sample ‐ specific QC (L1704848 ‐ 03) Surrogate spike % Recovery Acceptance Criteria (%R) (%R) Compound 248% 40 – 140% Chloro-octadecane Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 81 Extraction surrogate high – seriousness? • Chloro ‐ octadecane ‐ monitors extraction performance – “of aliphatic extraction only” • Positive bias – Actual results could be less than reported value – Data reported could be more conservative WHY IS THE SURROGATE RECOVERY SO HIGH? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 82 73

5/2/2017 Chromatographic interference, co ‐ elution? COD Surrogate Chromatogram should be included with report Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 83 EPH DUE Summary (multiple lines of evidence) • EPH – “OUT”: COD surrogate high bias ( “co ‐ elution” ) – “IN”: LCS / LCSD, OTP surrogate, MS/MSD, & blank – Field duplicate – 57% RPD – TPH (sample ‐ 03): 10, 14, 9 range hits (20 mg/Kg criteria) • If any bias present, it would be high bias – Actual result less than reported value • OK? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 84 74

5/2/2017 PCB Non ‐ Conformances (Page 74) Sample ‐ 03 TCMX surrogate – Sample specific QC Surrogate Surr Co Col l 1 Col 2 Col 2 % R % R Acceptance Accepta % R % R % R % R Crit Criteria eria 2,4,5,6-tetrachloro- 8 9 30 – 150 m-xylene 33 37 Decachlorobiphenyl 30 – 150 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 85 PCB DUE Summary (multiple lines of evidence) • Sample ‐ 03, contradictory MLE – “OUT”: TCMX surrogate – “IN”: LCS/LCSD, MS/MSD, DCB surrogate • Guidance: MS %R can overrule surrogate %R – Sample ‐ specific – Always a judgment call • But in this case… with surrogate %R <10% Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 86 75

5/2/2017 Surrogate recovery <10%, a” significant QA/QC variance (Appendix E) Data can be deemed unusable Rejection means it Dependent on intended use of data, never happened… Given our clean up verification application… For training purposes only (i.e. “no sample left”) in real life laboratory would/should have re-run or otherwise notify you if that wasn’t possible Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 87 PCB 1260 Field Duplicate Data -04 -04 -05 05 RPD RPD % RPD Cri RPD Criteri eria 30% 740 1230 49% 49% Not to exceed FDs indicate poor precision – is it laboratory performance, sampling technique or sample non ‐ homogeneity? All other DQIs acceptable for these samples, from a MLE perspective you could “over look” FD %RPD performance, EXCEPT… Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 88 76

5/2/2017 PCB Data Usability Evaluation Summary Samp Sample le ID ID or or Res Result lt Criteria Cr eria Bias Bi as / / Decision / De sion / rationale onale QC elemen QC element Qualifier alifier R Ignore result L1425103-03 <0.037 1,000 NA FD-RPD L1425103-04 740 1,000 indeterminate FD – RPD L1425103-05 1230 1,000 indeterminate FD Field duplicate discussion Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 89 Method Parameters Lab Sample ID Result RL Units CT ‐ GW Matrix QC Non ‐ %R / Valid DQ Assessment PMC Conformances %RPD Range 8260C 2 ‐ BUTANONE L1704848 ‐ 01 ND 5.0 ug/l 400 WATER LCS High 153 63 ‐ 138 potential high bias 8260C 2 ‐ BUTANONE L1704848 ‐ 01 ND 5.0 ug/l 400 WATER LCSD High 153 63 ‐ 138 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 01 ND 5.0 ug/l WATER LCS High 154 70 ‐ 130 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 01 ND 5.0 ug/l WATER LCSD High 154 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 01 ND 5.0 ug/l 350 WATER LCS High 155 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 01 ND 5.0 ug/l 350 WATER LCSD High 155 70 ‐ 130 potential high bias 8260C BENZENE L1704848 ‐ 01 ND 0.5 ug/l 1 WATER LCS Low 47 70 ‐ 130 potential low bias 8260C BENZENE L1704848 ‐ 01 ND 0.5 ug/l 1 WATER LCSD RPD 70 <=30 non ‐ directional bias 8260C 1,2 ‐ DICHLOROETHANE ‐ D4 L1704848 ‐ 02 ‐ ‐ ‐ WATER Surrogate Low 57.0 70 ‐ 130 potential low bias 8260C 2 ‐ BUTANONE L1704848 ‐ 02 ND 5.0 ug/l 400 WATER LCS High 153 63 ‐ 138 potential high bias 8260C 2 ‐ BUTANONE L1704848 ‐ 02 ND 5.0 ug/l 400 WATER LCSD High 153 63 ‐ 138 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 02 ND 5.0 ug/l WATER LCS High 154 70 ‐ 130 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 02 ND 5.0 ug/l WATER LCSD High 154 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 02 ND 5.0 ug/l 350 WATER LCS High 155 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 02 ND 5.0 ug/l 350 WATER LCSD High 155 70 ‐ 130 potential high bias 8260C BENZENE L1704848 ‐ 02 0.7 0.5 ug/l 1 WATER LCS Low 47 70 ‐ 130 potential low bias 8260C BENZENE L1704848 ‐ 02 0.7 0.5 ug/l 1 WATER LCSD RPD 70 <=30 non ‐ directional bias 8260C 1,2 ‐ DICHLOROETHANE ‐ D4 L1704848 ‐ 02 R ‐ ‐ ‐ WATER Surrogate Low 54.0 70 ‐ 130 potential low bias 8260C 2 ‐ BUTANONE L1704848 ‐ 02 R ND 5.0 ug/l 400 WATER LCS High 153 63 ‐ 138 potential high bias 8260C 2 ‐ BUTANONE L1704848 ‐ 02 R ND 5.0 ug/l 400 WATER LCSD High 153 63 ‐ 138 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 02 R ND 5.0 ug/l WATER LCS High 154 70 ‐ 130 potential high bias 8260C 2 ‐ HEXANONE L1704848 ‐ 02 R ND 5.0 ug/l WATER LCSD High 154 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 02 R ND 5.0 ug/l 350 WATER LCS High 155 70 ‐ 130 potential high bias 8260C 4 ‐ METHYL ‐ 2 ‐ PENTANONE L1704848 ‐ 02 R ND 5.0 ug/l 350 WATER LCSD High 155 70 ‐ 130 potential high bias 8260C BENZENE L1704848 ‐ 02 R 0.7 0.5 ug/l 1 WATER LCS Low 47 70 ‐ 130 potential low bias 8260C BENZENE L1704848 ‐ 02 R 0.7 0.5 ug/l 1 WATER LCSD RPD 70 <=30 non ‐ directional bias 8082A 2,4,5,6 ‐ TETRACHLORO ‐ M ‐ XYLENE L1704848 ‐ 03 ‐ ‐ ‐ SOIL Surrogate Low 8.00 30 ‐ 150 potential low bias 90 77

5/2/2017 Lunch 45 Minutes Connecticut Department of Energy and Environmental Protection Laboratory Case Narratives Michael Ainsworth HRP Associates, Inc. mike.ainsworth@hrpassociates.com Connecticut Department of Energy and Environmental Protection 1 78

5/2/2017 Laboratory Case Narratives Connecticut Department of Energy and Environmental Protection 1 Laboratory Case Narrative Key component of lab – EP communication: • States whether data meets RCP standards. • Lists non ‐ conformances and issues related to matrix interferences, sampling, lab analyses, quality control, etc. • Provides additional information regarding the samples and analytical results. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 2 79

5/2/2017 Case Narrative Examples General topics/categories : • Matrix Interferences • Reporting Limits • Analyte Issues • Physical Characteristics of Sample • Sampling Procedures • Lab Method Issues • Lab Quality Control/Acceptance Criteria/Surrogates • Lack of RCP Criteria Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 3 Case Narrative Examples “There were no anomalies associated with the reported data.” Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 4 80

5/2/2017 Case Narrative Examples Physical Characteristics “The VOA vials preserved with deionized water were received frozen upon custody transfer to laboratory representative.” • Sample is valid as long as: Seal is not broken Vial is not cracked Vial was frozen by the client or lab within 48 hrs Holding times have not been exceeded • Review the COC for time of collection and freezing Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 5 Case Narrative Examples Sampling Issues “The methanol VOA vial was cracked. We have extracted in house.” • RCPs were not met. • Is the data usable? Depends on stage of investigation High results may be usable for screening Use with multiple lines of evidence Resample if more accurate results are required Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 6 81

5/2/2017 Case Narrative Examples Sampling Issues “ The MeOH vial contained a large amount of soil as compared to the extractant (greater than the 1:1 ratio referenced in EPA Method 5035). The results reported from the diluted aliquot are therefore based on the sample as received.” • Result: data did not meet RCP criteria • Low bias • Is the data usable? Stage of investigation Levels detected CSM Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 7 Case Narrative Examples Matrix Interferences “ Due to matrix interferences, selected samples were analyzed for certain analyses on a diluted basis. In such cases, the reporting levels have been raised accordingly.” • Are contaminants of concern involved? • Are samples being used to meet RSR criteria? • Can the lab clean up and re ‐ run the sample within holding time? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 8 82

5/2/2017 Case Narrative Examples Sample Dilution “Sample dilution was required for high concentrations of target analytes to be within the instrument calibration range.” • Sample dilution is often required • Are raised Reporting Levels over RSR criteria? • Review diluted and undiluted results – may help Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 9 Case Narrative Examples Estimated Values “The result reported for TCE is an estimated value (“E”) because it was greater than the highest calibration standard analyzed.” • Results meet RCPs • Can data be used for quantitative purposes? • Results are only accurate within the calibration range and limitations of the equipment and method. • If there are two sets of data due to dilution, are both out of calibration range? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 10 83

5/2/2017 Case Narrative Examples QA/QC Blanks “Analyte is found in the associated blank as well as in the sample.” Significance depends on: • Which blank was it found in (lab, trip, or field blank)? • What substance and concentration? 10 X rule. • Contaminant of concern? • Certain compounds are common laboratory contaminants: Methylene chloride Acetone MEK Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 11 Case Narrative Examples Potentially Difficult Compounds “According to CTDEEP RCP Quality Assurance and Quality Control Requirements for VOCs by Method 8260, Table 1A, recovery for some VOC analytes has been deemed potentially difficult.” • RCPs list any compounds that are potentially difficult to quantify. • Methods 8260 and 8270 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 12 84

5/2/2017 Case Narrative Examples Potentially Difficult Compounds EPA Method 8260 Acetone Bromomethane Chloroethane Dichlorodifluoromethane Dibromochloromethane Hexachlorobutadiene 2 ‐ butanone (MEK) Trichlorofluoromethane 4 ‐ methyl ‐ 2 ‐ pentanone Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 13 Case Narrative Examples Potentially Difficult Compounds EPA Method 8270 Dimethyl phthalate 4 ‐ nitrophenol Phenol 4 ‐ methylphenol 2 ‐ methylphenol 2,4 ‐ dinitrophenol Pentachlorophenol 4 ‐ chloroaniline Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 14 85

5/2/2017 Case Narrative Examples Analytical Method Issues “This sample was analyzed for VOCs outside the EPA recommended holding time of 14 days per client request.” • How long after? 1 day? 10 days? • Data could possibly be used for screening or with multiple lines of evidence. • Not usable for RSR compliance • PCBs less prone to degradation after 14 days Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 15 Case Narrative Examples Laboratory Calibration Issues “ The following analytes do not meet RCP criteria in the SVOC initial calibration (ICAL) with Response Factors of <0.05: 2,4 ‐ Dinitrophenol, 4,6 ‐ Dinitro ‐ 2 ‐ methylphenol, Hexachlorocyclopentadiene and Pentachlorophenol.” • Results based on low response factors (RF) for initial calibration (ICAL) are estimated values. • Impact depends on: Compounds contaminants of concern? Use of data RLs over RSR criteria? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 16 86

5/2/2017 Case Narrative Examples Lab Method Issues “For Method 6010, only RCRA 8 metals were requested and reported.” • Similar for PAHs (part of Method 8270) or any other methods. Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 17 Case Narrative Examples Method Acceptance Criteria “Benzidine percent recovery (30%) is outside individual acceptance criteria (40 ‐ 140%), but within overall method allowances. Results of the following samples are considered to have a potentially low bias.” “Chloroethane percent recovery (138%) is outside individual acceptance criteria (70 ‐ 130%), but within overall method allowances. Results are considered to have a potentially high bias.” Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 18 87

5/2/2017 Case Narrative Examples Method Acceptance Criteria • 20% of total number of compounds can be outside of acceptance criteria for method compliance • Contaminants of concern? • Use of results? • RSR criteria? Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 19 Case Narrative Examples Surrogates ‐ SVOCs “ Acid surrogate recovery outside of control limits. The data was accepted based on valid recovery of remaining two acid surrogates.” Surrogate recovery for SVOC analysis Surrogate % Recovery Within Limits? 2, 4, 6 ‐ Tribromophenol 11% Terphenyl ‐ d14 86% Phenol ‐ D5 78% Acceptable Limits are 30% ‐ 130% Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 20 88

5/2/2017 Case Narrative Examples Surrogates ‐ VOCs “ Surrogate recovery outside of control limits. The data was accepted based on valid recovery of the remaining surrogates with three required by program methods.” Surrogate Recovery for VOC analysis Constituent Surrogate Recovery Within Limits? Dibromofluoromethane 62% 1, 2 ‐ Dichloroethane ‐ d4 112% Toluene ‐ d8 106% 4 ‐ Bromofluorobenzene 101% Acceptable Limits are 70% ‐ 130% Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 21 Case Narrative Examples Acceptance Limits for Duplicates RPD “The Relative Percent Difference (RPD) of the sample duplicate exceeded the QC control limit of 20%; however precision is demonstrated with acceptable RPD values for MS/MSD.” RPD within limit? Constituent MS/MSD Duplicate Nickel 5 21 4 Lead 57 Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 22 89

5/2/2017 Case Narrative Examples No RCP Criteria “There are currently no RCP criteria for one or more analytes or methods requested, however QC data has been reported and meets the requirements of each non ‐ RCP method.” • Information statement • Some metals, waste characterization tests, etc. • Understand your project’s objectives and laboratory SOPs • If any listed analytes are important to the Site: Request additional QA/QC information is necessary Document that equivalent QA/QC was performed Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 23 Case Narrative Examples “This compound was over the instrument calibration range and was not re ‐ analyzed from the Methanol vial because a minimum 50x dilution factor is required. The dilution factor combined with reporting limit would mean the final concentration would be BRL.” If a comment is unclear, Contact the lab! Connecticut Department of Energy and Environmental Protection Connecticut Department of Energy and Environmental Protection 24 90

5/2/2017 Case Study #1 Tina M. Clemmey Gail L. Batchelder, Ph.D., P.G., L.E.P. Ensafe Inc. HRP Associates, Inc. tclemmey@ensafe.com Gail.Batchelder@hrpassociates.com Connecticut Department of Energy and Environmental Protection 1 Case Study #1 Objectives Provide an opportunity to go through the DQA/DUE process for a specific site. The focus on this case study is the DQA. • The DQA will be guided • The DUE will be presented 2 91

5/2/2017 Case Study #1 Scenario • Release from an in ‐ ground wastewater treatment sump. • Release investigated and remediated. • Evaluate groundwater data to determine if remediation was successful. • For purposes of this exercise, the analytical results will be compared to the GWPC. 3 DQA/DUE Process DQA Identify nonconformances and summarize. DUE Evaluate the effects of nonconformances on usability of sample data in relation to the intended purpose or alternative decision ‐ making purposes. 4 92

5/2/2017 Step 1: Perform the DQA • Reminder: Appendix C of the DQA/DUE Guidance lists the information to be reviewed during a DQA. • Summarize nonconformances on a DQA Worksheet. 5 Guided DQA • Review laboratory report – Is the report complete? (The report for this case study is complete) • Laboratory Analysis RCP QA/QC Certification Form. • Chain of Custody Form. • Case Narrative Report. • Analytical Results. • QC Results. – Cross ‐ reference batch numbers with sample numbers. • Complete a DQA Worksheet – Note nonconformances only. 6 93

5/2/2017 About DQA Worksheets • Example worksheets may be modified. • The example worksheets provided include RSR criteria, results, and preliminary DUE findings; ‐‐ this may work for smaller projects, but could be too cumbersome for large projects. • Complete as you go through case narrative, lab QC information, other DQA tasks 7 Example DQA Worksheet • Electronic versions, databases, or spreadsheets may be used. • Contact your lab to see if they can provide a DQA or if they have a portal that allows you to pull and compile the data along with the respective QC samples. 8 94

5/2/2017 Example DQA Worksheet • For the purpose of this training, we will go through the DQA process MANUALLY 9 Example DQA Worksheet CASE STUDY 1 RCP DQA Laboratory: JGBT SDG: 08R-2469.0 Date Samples Collected: 4/17/2008 RCP Certification Form Included: Yes Laboratory Case Narrative Included: Yes Sample # Lab # Location # Compound QC % Rel. Results GWPC Comments Outlier Rec. % (ug/L) Diff. This part can be entered in advance This part is entered as you find issues 10 95

5/2/2017 Data Package Review Become Familiar with your Data Package CASE STUDY 1 – DATA DELIVERABLES RCP Certification Form – page 1 of 54 JGBT Case Narrative – page 2 and 3 of 54 Environmental Inc. Sample Summary – page 4 of 54 Data Lab Reports – page 5 through 33 of 54 Deliverables QC Report – page 34 through 50 of 54 Batch Association – page 51 and 52 of 54 Method Summary – page 53 and 54 of 54 Chain of Custody Form – Last page of data package 11 Review of Laboratory Report Package Review Laboratory Analysis RCP Certification Form (LCF): – Are all the questions in the LCF answered? – Note which questions are answered “NO.” Are these “NO” responses fully explained in the Case Narrative Report? – Laboratory should not have made any changes to Form 12 96

Recommend

More recommend