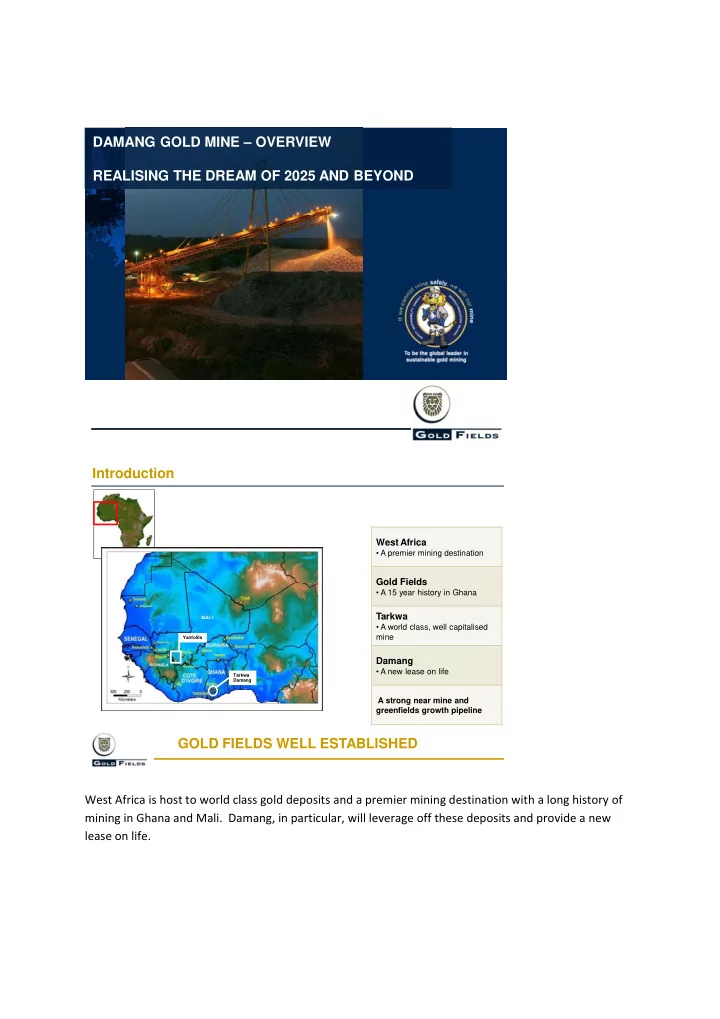

DAMANG GOLD MINE – OVERVIEW REALISING THE DREAM OF 2025 AND BEYOND Introduction West Africa • A premier mining destination Gold Fields • A 15 year history in Ghana Tarkwa • A world class, well capitalised mine Yanfolila Damang • A new lease on life Tarkwa Damang A strong near mine and greenfields growth pipeline GOLD FIELDS WELL ESTABLISHED West Africa is host to world class gold deposits and a premier mining destination with a long history of mining in Ghana and Mali. Damang, in particular, will leverage off these deposits and provide a new lease on life.

Regional Strategy • “If we cannot mine safely, we will not mine” Secure The Future • Stakeholder relationships • Maintain stable power supply • Tarkwa CIL Build-up, HPGR Project • Tarkwa South Heap Leach Reprocessing Opportunity Sweat the Assets • Damang Secondary Crusher Installation • Business Process Re-Engineering • Regional exploration focus • Damang: Near Mine Exploration Grow Gold Fields • Mali: Komana-Sankarani Project • Growing towards 1 Moz attributable in 5 years FOCUSED ON GHANA AND MALI HISTORICAL OVERVIEW - DAMANG • 1990 to 95 – Discovery and exploration of the Damang ore body; • 1996 to 97 – Construction of Damang mine and mill; • Aug to Nov 97 – Commenced mining in August with first gold pour in November; • January 2002 – Change of ownership to Gold Fields Ltd (71.1%) and IAMGOLD (18.9); Government of Ghana owns 10%; • 2004 to 2006 - US$55M paid in dividend The Damang Ore body was first discovered between 1990 and 1995 when Ranger Gold entered the area to mine the tailings of the Abosso Gold Mine. In 1997 the construction of the Damang mine and mill was completed and mining commenced in August with the first gold pour in November. In January 2002, Gold Fields acquired a stake in the Damang gold mine. Gold Fields owns 71.1% of this asset while IAMGOLD and the Ghanaian government each own 18.9% and 10%, respectively.

OUR VISION Damang A leading Ghanaian gold mine delivering ongoing optimized returns to its stakeholders whilst excelling in sustainable development 1. 1. Rated as the safest operating mine in Ghana in 2004 (Ghana Chamber of Mines); 2. GF Chairman’s Safety Shield for 2008; 3. Best Mine in Ghana in 2009 based on Occupational Injury Statistics (Minerals Commission) 4. Environmentally Most Committed Company in the Mining Sector in 2004&5 (EPA award). GLOBAL LEADER IN SUSTAINABLE GOLD MINING Damang’s vision is strongly aligned with the Group vision of being the global leader in sustainable gold mining. To this end, Damang has upheld Gold Fields’ number one value of safe production and was recognized as the safest operating mine in Ghana in 2004. It was also awarded the Chairman’s safety shield in 2008 as well as the award for Best Mine in Ghana in 2009 based on Occupational Injury Statistics as defined by the Minerals Commission. Damang has also upheld the environmental management standard and was awarded the EPA award for the most environmentally committed company in the mining sector in 2004 & 2005.

SENIOR MANAGEMENT General Manager Alfred Baku Metallurgical Manager Charles Amoah Expatriates & Senior Officials Engineering Manager Christo Vilj oen 35 30 30 30 30 30 30 30 Mining Manager 30 26 26 Gareth Phillips 25 Local Affairs Manager 28 26 25 24 R obert S iaw 20 21 21 19 Environmental Manager 15 18 16 Francis Nyame 10 Group Security Manager 5 0 8 9 13 20 21 24 25 28 Dries Hugo 0 HR Manager 2002 2003 2004 2005 2006 2007 2008 2009 2010 Charles Kwasi Klutse Group IT Manager Expat Quota Expats Senior Officials S teve Larbi MR Manager Marcus Brewster F&A Manager Gabriele Decina Safety Manager Andre von S olms Damang has a strong management structure. More importantly, concerted efforts to improve the mix of expatriates and local management has been extremely successful resulting in local senior official appointments increasing from zero to 28 in the last 8 years, an achievement we’re very proud of. ENVIRONMENTAL EXCELLENCE ENVIRONMENTALLY MOST COMMITTED MINE IN GHANA

In line with the vision of sustainability, Damang is committed to maintaining the environment through responsible mining as well as various outreach programmes that enhance the environment as well as uplift local communities. KEY PERFORMANCE INDICATORS F2010 F2010 Description Unit F2007 F2008 F2009 Plan Outlook Ore Mined Mt 3.1 4.1 4.4 3.9 3.8 Tons Milled Mt 5.3 4.5 5.0 5.2 5.0 Head Grade g/t 1.20 1.43 1.34 1.42 1.39 Capex US$M 32 28 17 25 30 Operating % 26 26 25 31 44 Margin Damang has had a commendable history of solid operating performance in terms of key performance indicators. Worth noting is that it has managed to increase operating margin by almost 70% in the last 3 years.

DAMANG PROFILE Steady State: Production (koz) Production - 240 koz per annum. 300 Cash cost - US$590/oz 250 NCE - US$690/oz 200 150 Crushing facilities upgrade for higher grade hard ore. 100 • Significant potential for margin improvement. 50 0 F2007 F2008 F2009 F2010 Plan F2010 Steady Optimization of mining and processing costs. Outlook State Strong near mine exploration focus to extend LOM from 2018 to 2025 and beyond. “Super” pit opportunities. • Mine Huni and Juno pits concurrently with DPCB. • Ensure consistent supply of high grade fresh ore. Resources 74.9Mt @ 1.8g/t = 4.3 Moz Reserves 36.1Mt @ 1.6g/t = 1.8 Moz LOM Strip Ratio 3.3 TARGETING A 15 YEAR LIFE OF MINE The secondary crusher was commissioned at the end of April which strategically alters the future of this operation. The secondary crusher will enable the mining and processing of fresh, higher grade ore. This has prompted a second strategic imperative i.e. in the area of exploration for fresh ore. The focus will be on core exploration across the lease area, targeting fresh, high grade sources of Damang style hydrothermal mineralization along the entire 18km strike length of the Damang ore body. The initial focus is on opportunities more proximal to the plant, starting in the vicinity of the existing Greater Damang Pit, where there’s an opportunity to create a super pit, and in the Amonada ‐ Tomento corridor. More detail is provided in the Damang exploration presentation. Damang currently has 4.3 million ounces of resource and 1.8 million ounces of reserves and strip ratio of 3.3.

MINING OPERATIONS • Mining via contractor (AMS) under AGL supervision, • Daily production 50kt; Yearly Production 18.0Mt, • Currently mining in three pits: DPCB, Tomento East and Rex • Current mining fleet: 4 x 984 Liebherr Excavators, and 17 x CAT777 100t Dump trucks, • Grade Control ‐ 12m benches (hydrothermal pits only), • Drill & Blast – 6m benches and Mining – 3m flitches, • Ore haulage from Satellite pits ~25km from ROM undertaken by Ghanaian contractor (Engineers & Planners), • Mining operation: 2 shifts (day & night) with 3 crews, • AMS workforce is 343 (7 Expatriates and 336 Nationals), and • E&P workforce is 153 (1 Expatriate and 152 Nationals). In terms of mining operations, Damang is currently contractor mined by Australian mining contractors AMS under AGL supervision. Daily production is at 50,000 tons and yearly production is at 18 million tons. We are currently mining in three pits, namely the Damang Pit Cut Back, Tomento East and Rex. The fleet is comprised of 4 Liebherr Excavators and 17 777 CAT Dump trucks. Grade control is conducted by means of 12m benches while drill and blasting is by means of 6m benches and mining through 3m flitches. Hauling is conducted by a Ghanaian contractor and distances are approximately 25km.

DAMANG – OPERATIONS PLAN HUNI DPCB JUNO TOMENTO NORTH LIMA SOUTH TOMENTO EAST BONSA NORTH AMOANDA 12KM REX ABOSSO UNDERGROUND T CONTRACTORS & FUEL STORAGE AEL Magazine AMS Office & Workshop E&P Shell Fuel Storage

PROCESSING FACILITY PROCESS FLOW ROM Pad Gyratory Pebble CV05 CV06 Crusher Crusher CV02 FE01 Reclaim Stockpile CV04 CV07 CV01 Scats CV08 Stockpile SAG Mill FE01 Lime FE02 FE03 FE04 CV03 SN020 SAG u/s Gold Room Ball Mill Dore Bullion AW & Elution Column Loaded Carbon Barren Carbon Ball Mill d/c Recirculated AARL Strip load Carbon Safety Trash Screen Screen o/f Cyclones u/f Cyanide Oxygen Thickener CIL Tanks Hydrogen Peroxide Knelson Concentrator Decant Recycled to Gemeni Table Process Pond Gravity Concentrate

ROM & COS CRUSHING • Primary Crusher - Krupp 54” x 74” Gyratory Crusher - 600kW Hyundai 12pole 3300V, 492rpm motor - Capacity of 2000tph - Feed F80 = 600mm, Product P80 = 140mm • Krupp variable speed apron feeder - AF18 x 6.361/D4 model, 6.361m x1.8m wide,D4 bulldozer tracks & rollers. 2500tph capacity & speed variance from 0-.29m/sec. • Conveyor belt - Discharge conveyor (CV01) – 1600mm x 236m with speed of 1.5m/s & capacity up to 2400tph - Reclaim conveyor (CV02) – 1600mm x 261m - mill feed conveyer (CV03) – 1000mm x 600m with speed of 1.02 m/s

MILLING SAG mill – 5,8 MW currently run at 6,2 MW, Ball mill – 5,8MW (slipper pad mills/Combi flex Flender gearbox) GENERATING PLANT • 24 Diesel Driven Generators – 17.5MW. Additional generators will ordered to cater for the Secondary crusher. •LPG Storage facility

Recommend

More recommend