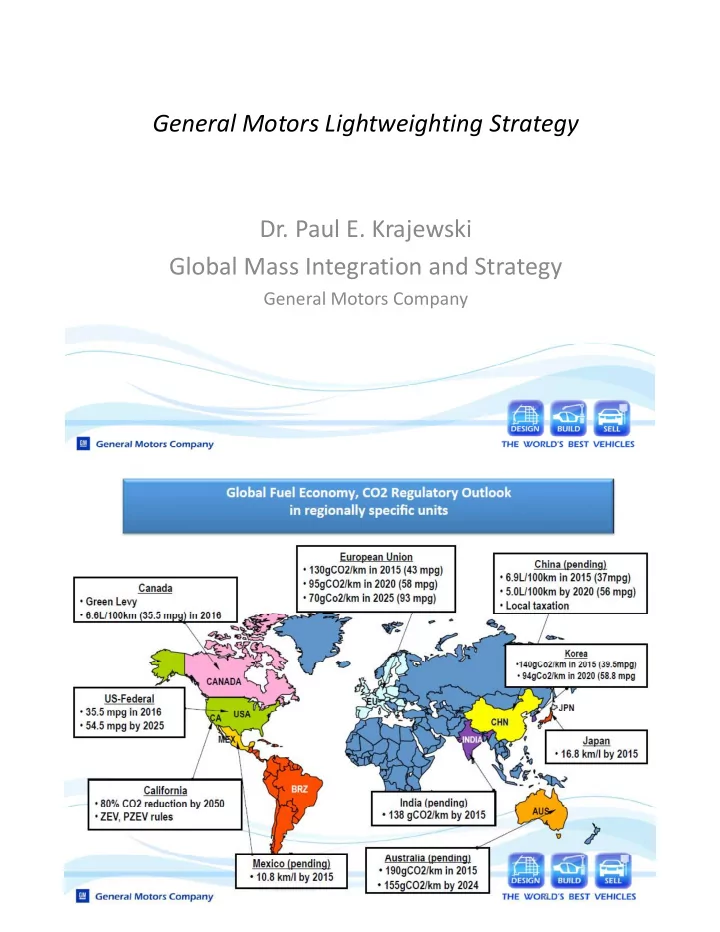

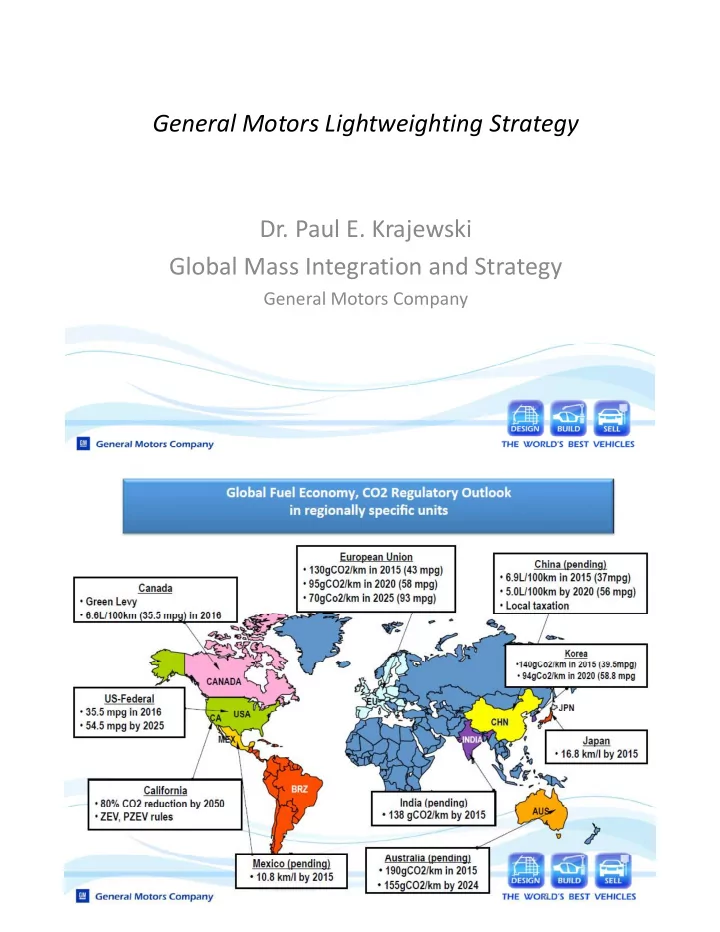

General Motors Lightweighting Strategy Dr. Paul E. Krajewski Global Mass Integration and Strategy General Motors Company

Vehicle Lightweighting Global CO 2 / Fuel Economy requirements will necessitate significant vehicle lightweighting. Expect 1-2 TWC reduction in mass for most vehicles. Lightweight materials will play a significant role in enabling mass reduction. GM Has Long History of Lightweight Materials Innovation 1961 Magnesium Instrument Panel 1953 Fiberglass Body Panels 1969 Chevy Aluminum Big Block

Recent Lightweight Materials Innovations Press Hardened Steel Magnesium Decklid Aluminum Shock Towers Aluminum Doors Carbon Fiber Hood Aluminum Body Structure Lightweighting Strategy Efficient Fundamentals Premium Matls & Mfg Processes Cost (Applied Independent of Material CFRP + Aluminum + Up type to Minimize Mass & Cost) Magnesium PHS + Aluminum AHSS/UHSS/PHS Baseline 20% 0% 5% 10% 30% 40% Material Percent Below Industry Material Utilization Regression Line Right Selection Customer Sizing Requirements Cost Down

Customer Focus Means understanding what the customer expects. Delivering a vehicle that exceeds their expectations Vehicle must be priced / sized consistent with competition Provide best customer driving experience low operating costs and outstanding quality. Camaro Z28

Understanding the Customer increase speed on the Camaro Z28, Chevrolet jettisoned just about everything that added weight but wasn't critical. That includes carpeting in the trunk, insulation and every speaker but one Vehicle mass reduced by 140 kg. Efficient Fundamentals Topology Optimization Material Selection Gage Selection Material Utilization Independent of material type or vehicle platform

ATS Every Gram, Every Engineer, Every Day ATS Material Utilization (Lightening holes & scalloped flanges) 2.8 kg eliminated

Premium Materials Strategic Application Efficient Design Cost Effective Manufacturing Enabled CTS Aluminum Door Saved 18kg/vehicle from the most mass efficient steel door systems in the industry.

Summary All vehicles will required significant lightweighting to meet post 2020 CO 2 / FE targets. Lightweighting will be achieved through a combination of efficient fundamentals and premium lightweight materials. Need strategic focus to ensure that the enterprise and supply base are ready for these materials.

Recommend

More recommend